Rock creep rupture measuring method after peak strength

A test method and technology for rock samples, applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve the problems of not considering the increase of confining pressure, not considering the creep re-rupture, unable to reflect the creep effect, etc. To achieve the effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

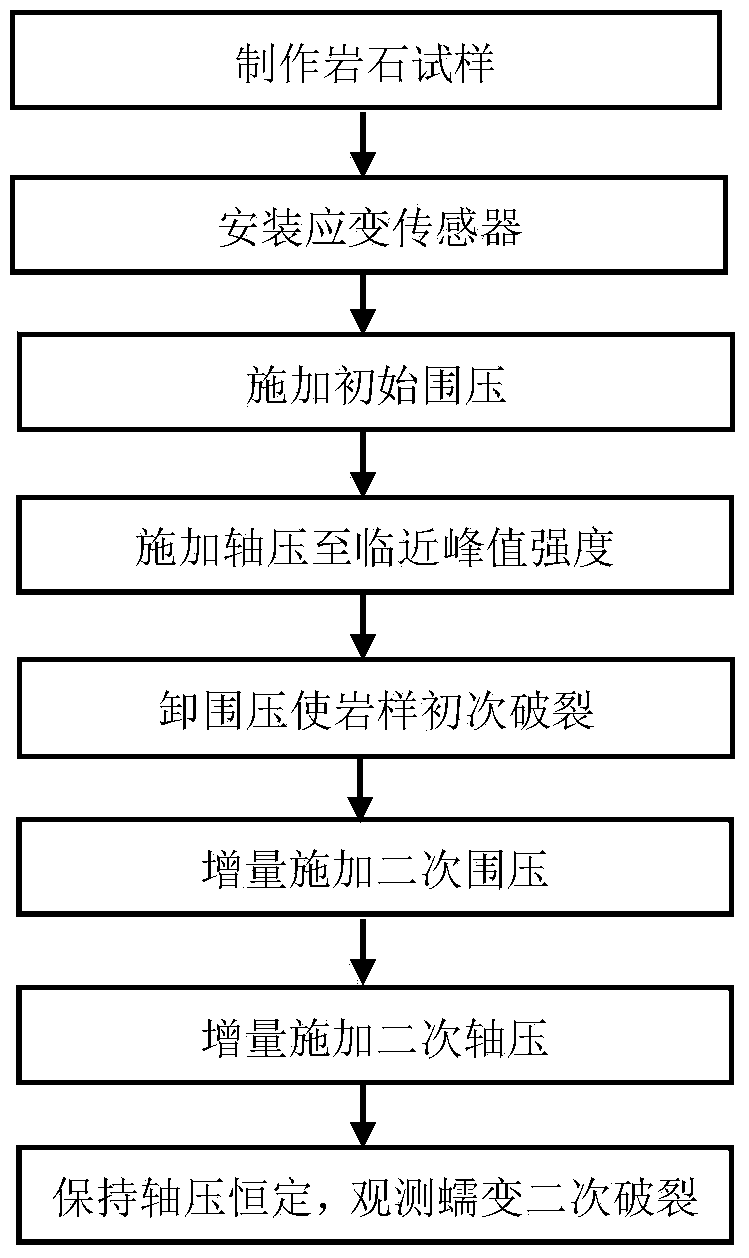

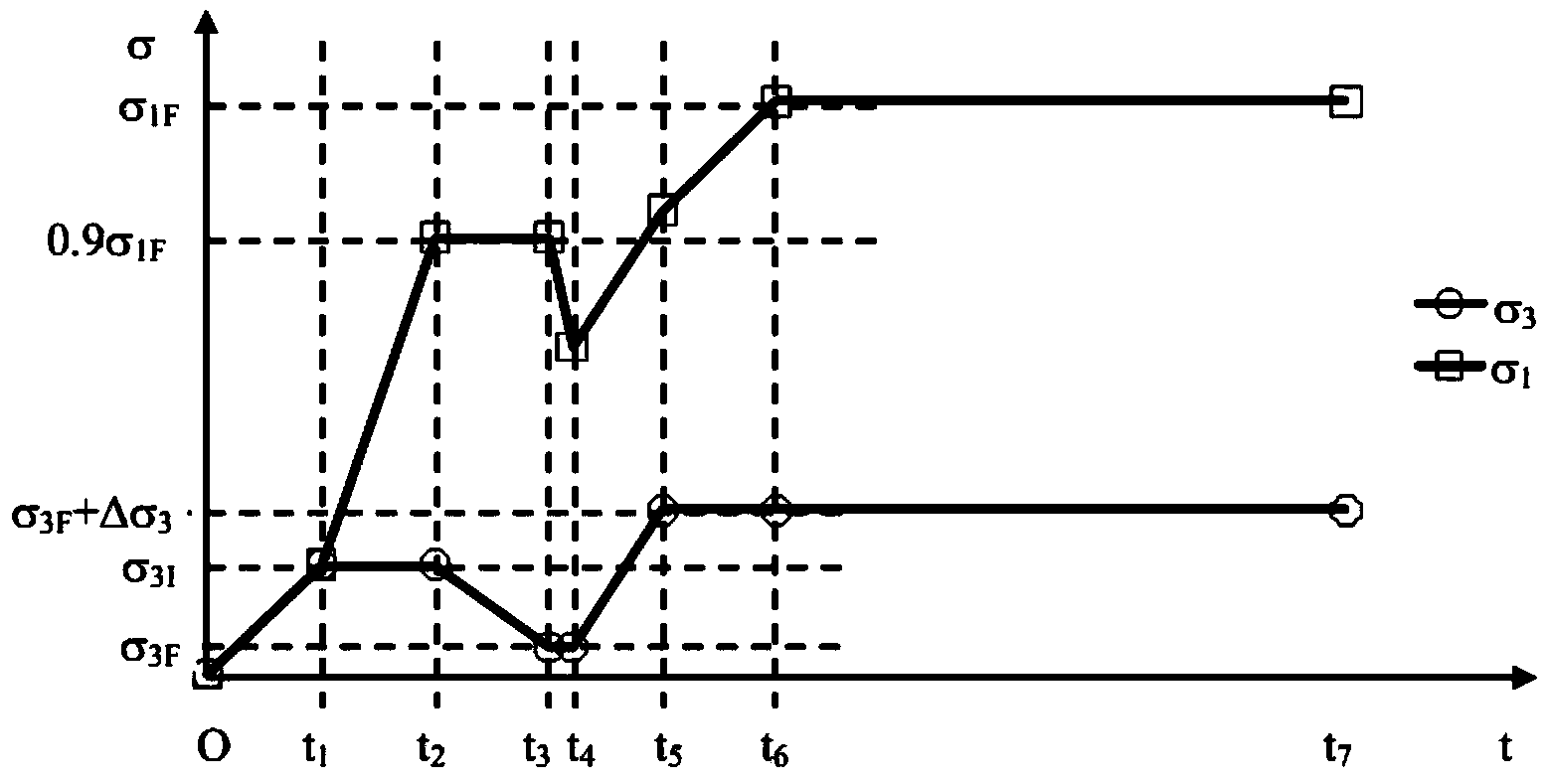

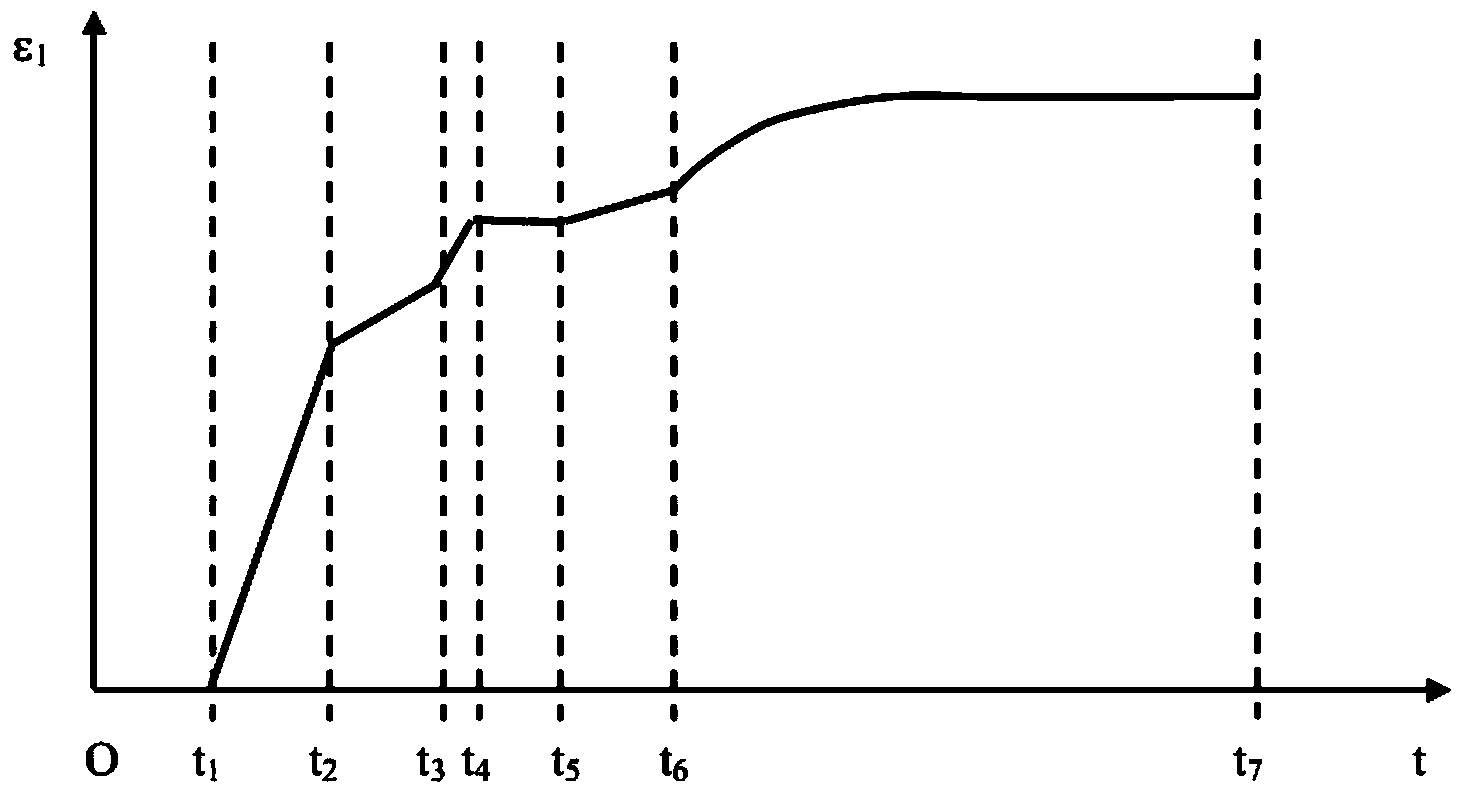

[0028] After the excavation of the surrounding rock of the underground cavern, on the basis of the original in-situ stress, the radial stress increases and the normal stress unloads. This method adopts the same stress path as that of engineering rock mass excavation, the confining pressure simulates the normal stress, and the axial pressure simulates the radial stress. The failure of the engineering rock mass after excavation is mainly caused by the unloading of the normal stress. Therefore, this method breaks the sample into the post-peak deformation stage by unloading the confining pressure under the initial stress state, and then adds the confining pressure to simulate the stress in the engineering rock mass. Support and reinforcement measures such as lining, and finally apply axial pressure to conduct creep tests to simulate long-term deformation and rupture laws of engineering rock mass. Therefore, the loading path of this method truly reflects the stress state and force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com