Optimum design method of replacing steel with plastic for auto parts based on CAE simulation technology

A technology of auto parts and optimization design, applied in the field of optimization design of mechanical products, in the field of optimization design of auto parts with plastic instead of steel, it can solve the problems of conservative optimization design, insignificant effect of light weight, increase production cost, etc., and achieve optimized assembly. Craftsmanship, the effect of lightweighting is remarkable, and the effect of improving rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

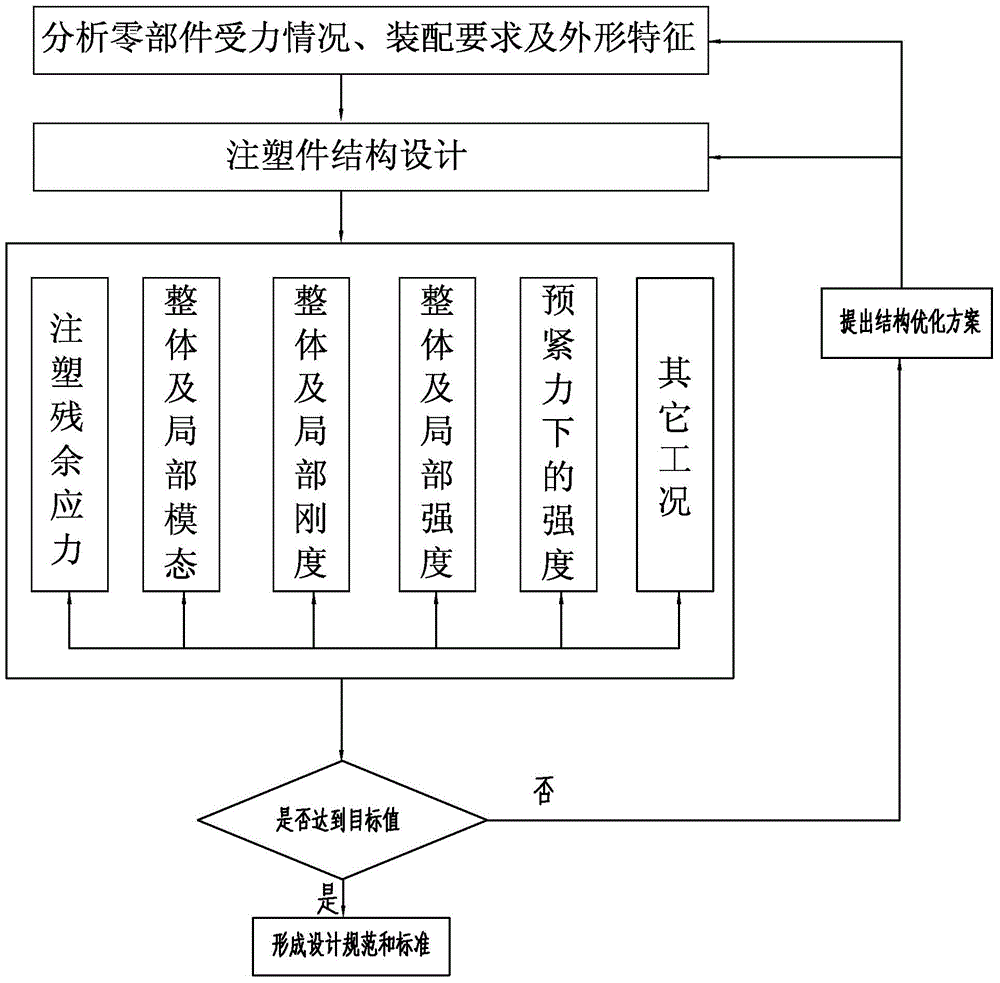

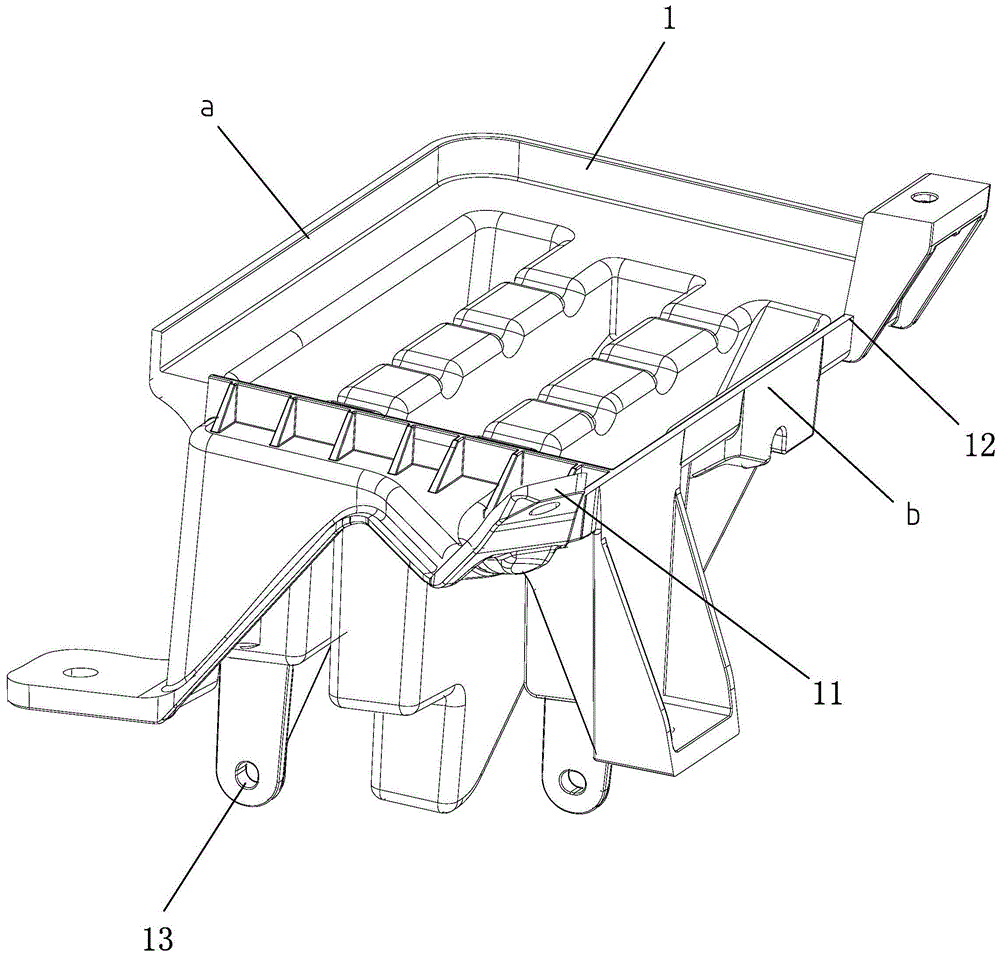

[0023] Such as figure 1 As shown, in this embodiment, the stamped part bracket of the automobile battery is selected for optimal design with plastic instead of steel, and the shape, wall thickness, layout and arrangement of the plastic battery bracket 1 of the battery are preliminarily designed according to the stress of the stamped part bracket of the battery and the assembly position. According to the analysis requirements, establish a finite element mesh model and set materials, properties, boundaries, load conditions, etc., and use CAE analysis to perform the following analysis and simulation on the battery plastic bracket 1 that has completed the preliminary design. The allowable target value considers the design safety Coefficient, stiffness, and strength analysis consider the influence of residual stress of injection molding process.

[0024] (1) Injection moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com