Trench-type MOS rectifier and manufacturing method thereof

A manufacturing method and ditch technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high leakage current, reduced reliability, and reduced forward and reverse surge capabilities of Schottky diodes , to achieve the effect of low forward bias voltage and small reverse leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

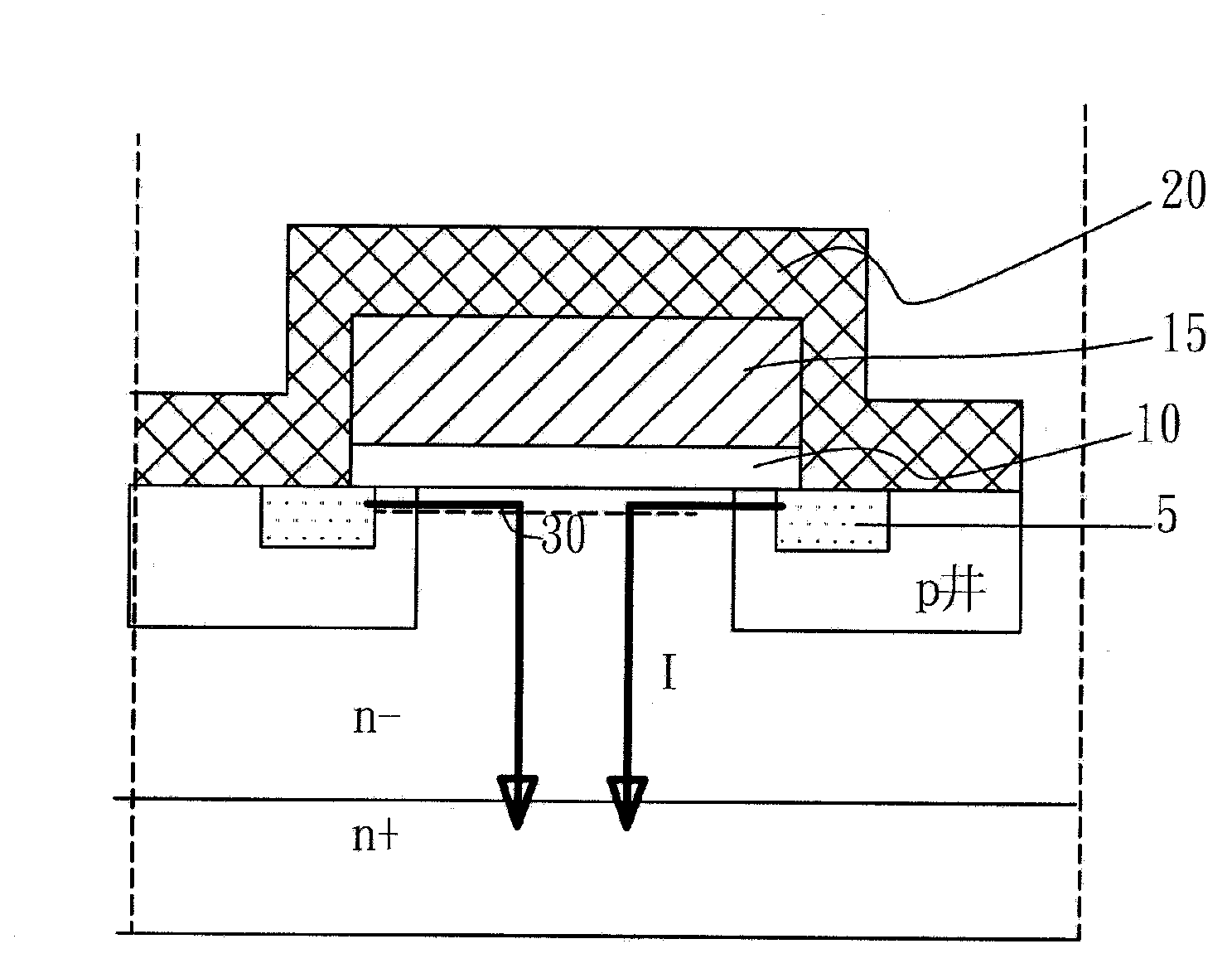

[0046] The present invention discloses a trench-type MOS device structure, comprising: a planar MOS structure is formed on a platform of an active region, and an adjacent side of the platform has a trench in the active region. The active region trench is formed in the n- epitaxial layer on the heavily doped n+ semiconductor substrate. The active region trench has a trench gate oxide layer formed on the bottom and sidewalls of the trench and a p-type doped polysilicon layer formed thereon. A top metal layer is formed on the active region, connecting the gate and source of the planar MOS structure and the polysilicon layer of the active region trench.

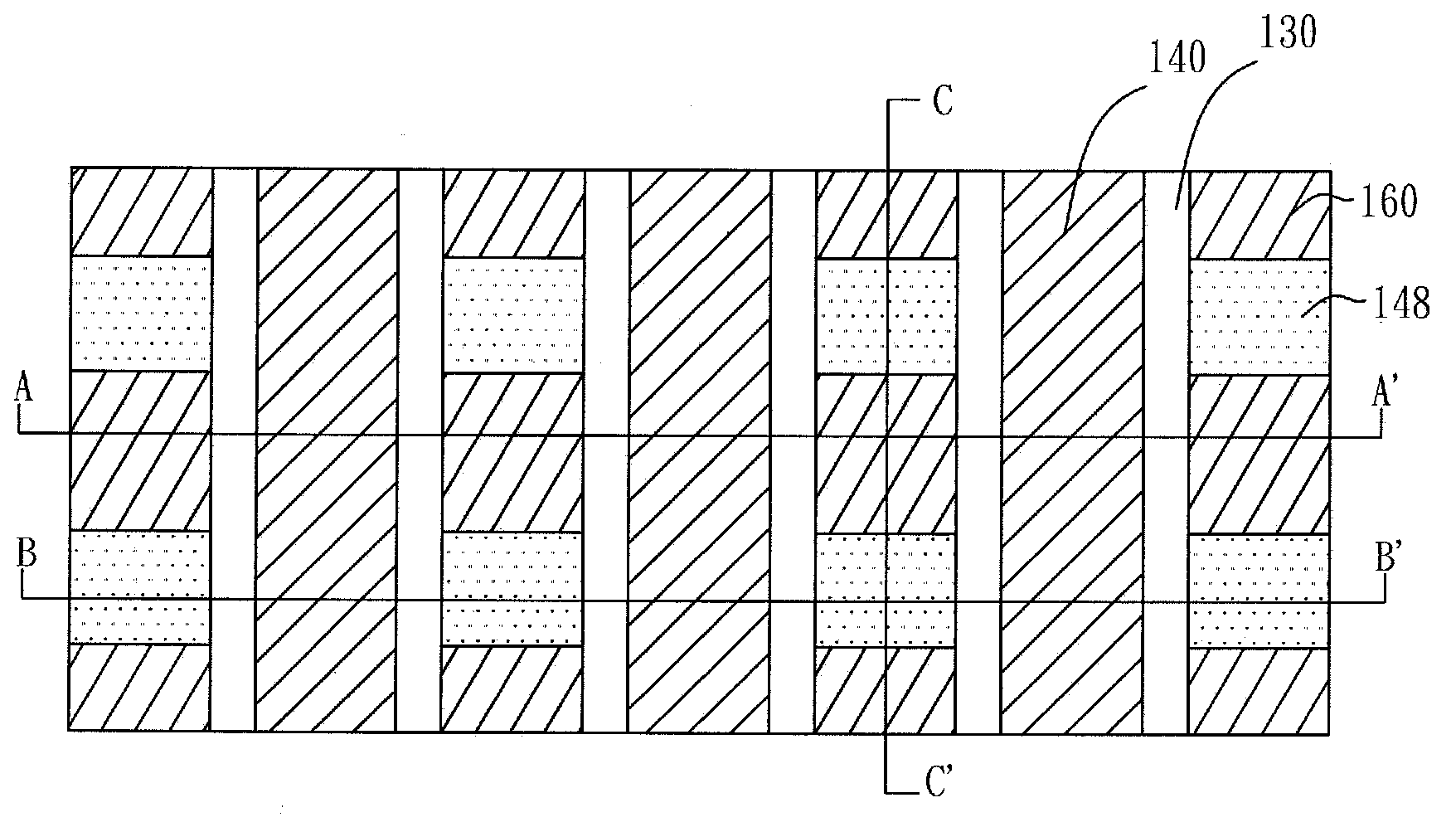

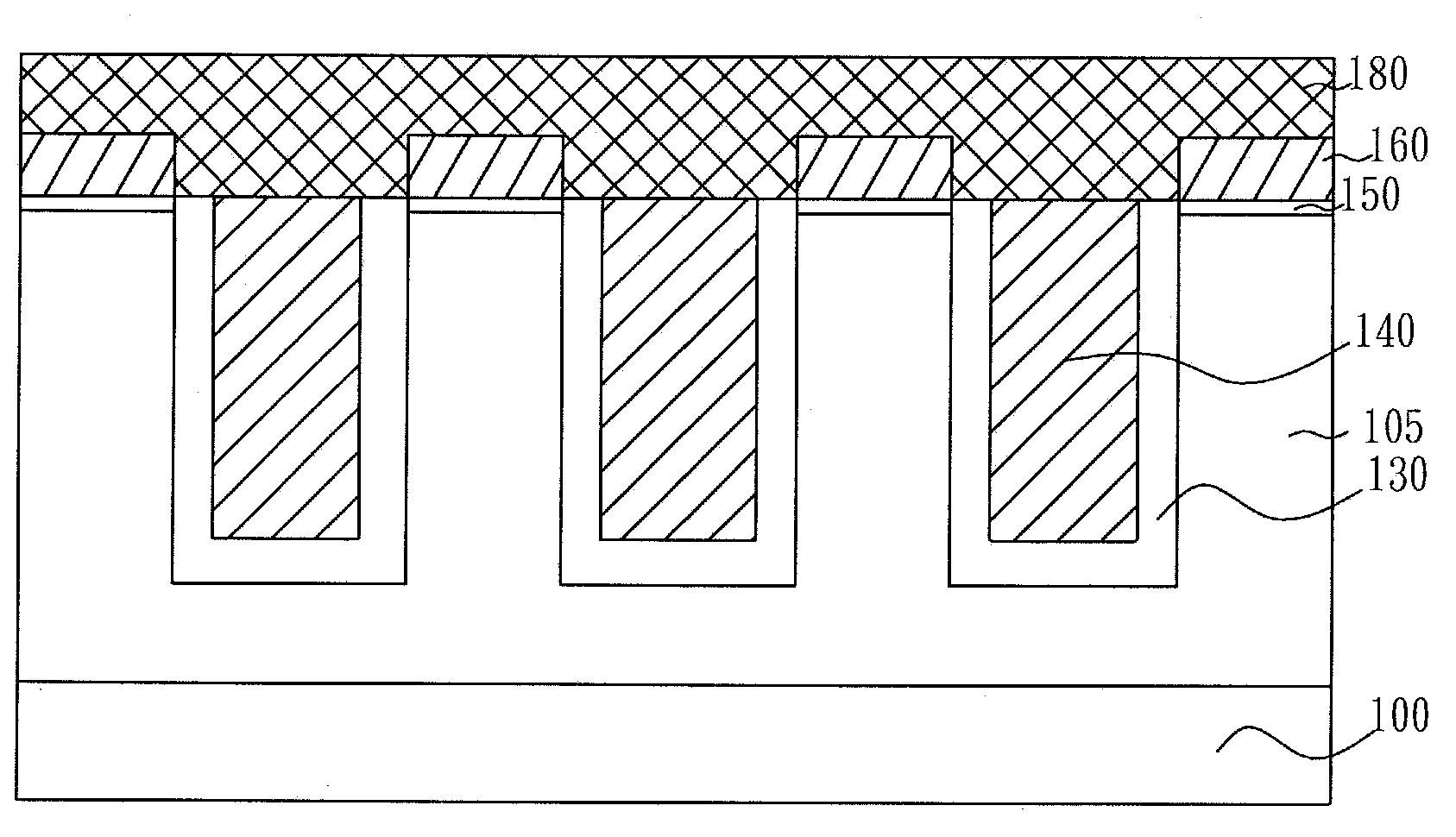

[0047] The structure of the trenched MOS device structure (excluding the top metal layer) of the present invention with multi-platform and multi-active region trenches, please refer to Figure 2A Top view shown. Figure 2B show edge Figure 2A A schematic diagram of the cross-section of the trench MOS device on the A-A' line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com