Trench type MOS rectifier and manufacturing method thereof

A manufacturing method and ditch technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced reliability, high leakage current, and reduced forward and reverse surge capabilities of Schottky diodes, etc. , to achieve the effect of small reverse leakage and low forward bias voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

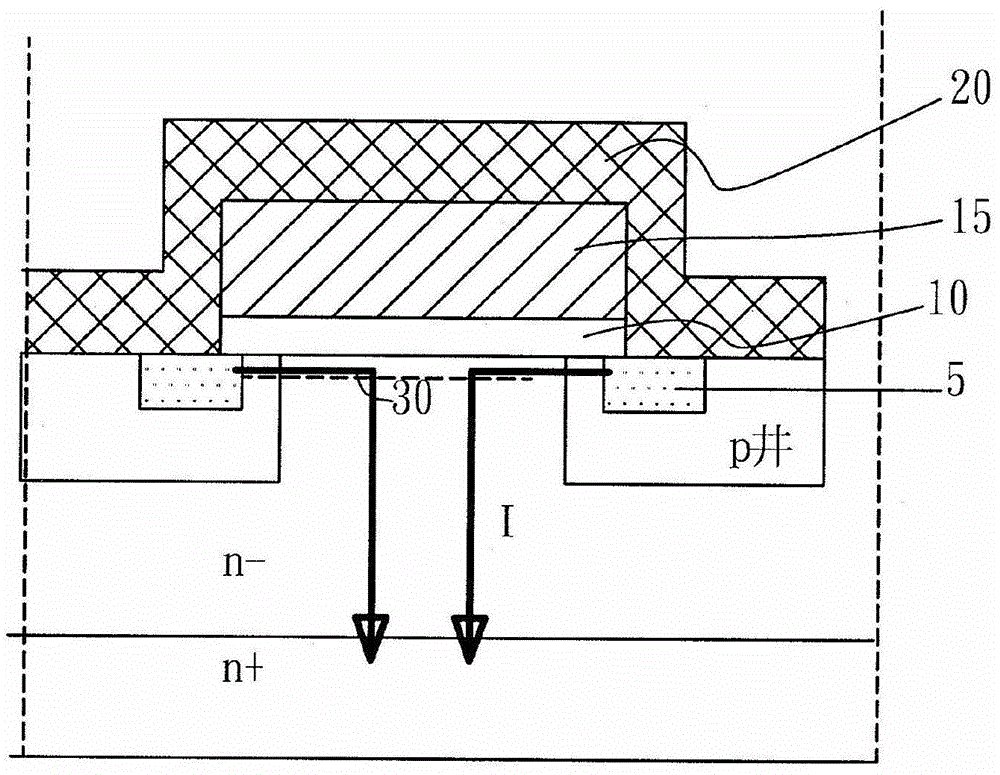

[0046] The present invention discloses a trench type MOS device structure, including: a planar MOS structure is formed on the platform of the active area, and there is a trench in the active area on the adjacent side of the platform. The trench in the active region is formed in the n- epitaxial layer on the heavily doped n+ semiconductor substrate. In the ditch of the active region, a ditch gate oxide layer is formed on the bottom and side walls of the ditch and a p-type doped polysilicon layer is formed thereon. A top metal layer is formed on the active area, connecting the gate, the source of the planar MOS structure and the polysilicon layer on the trench of the active area.

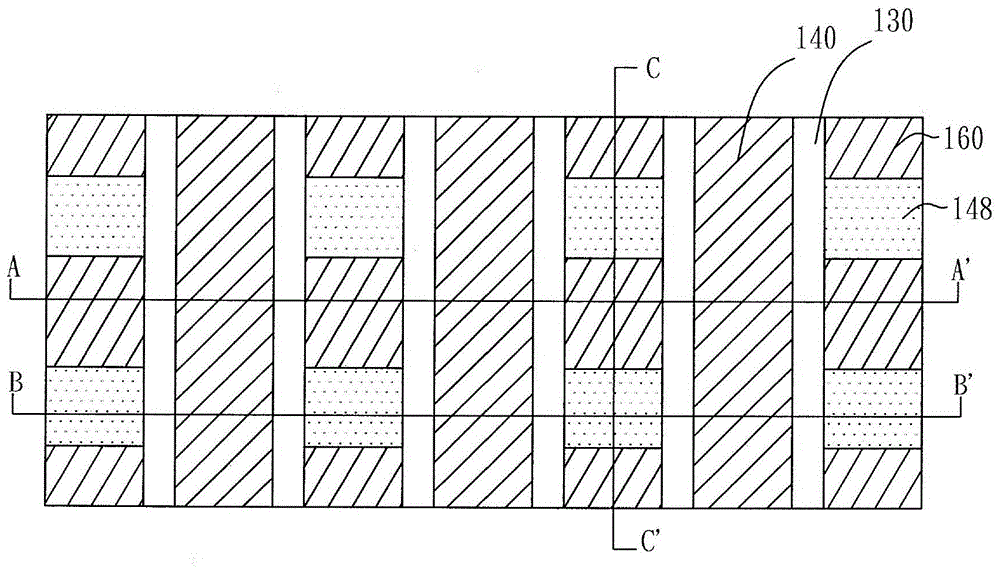

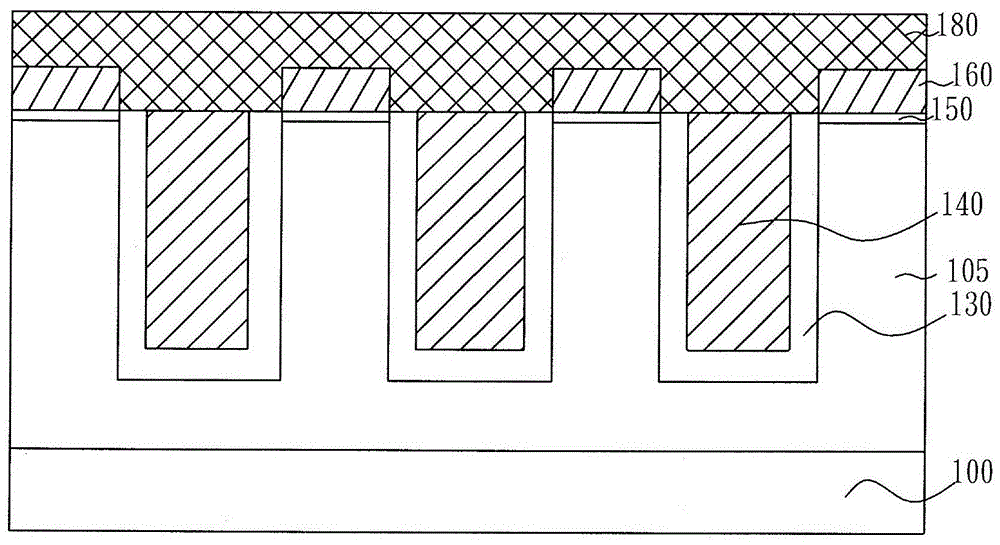

[0047] The trench type MOS element structure of the present invention (excluding the top metal layer) multi-platform and multi-active area trench structure, please refer to Figure 2A The top view shown. Figure 2B Show edge Figure 2A The cross-sectional schematic diagram of the trench MOS device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com