High-barrier SiC JBS device and preparation method thereof

A device and high-potential technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large chip reverse leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

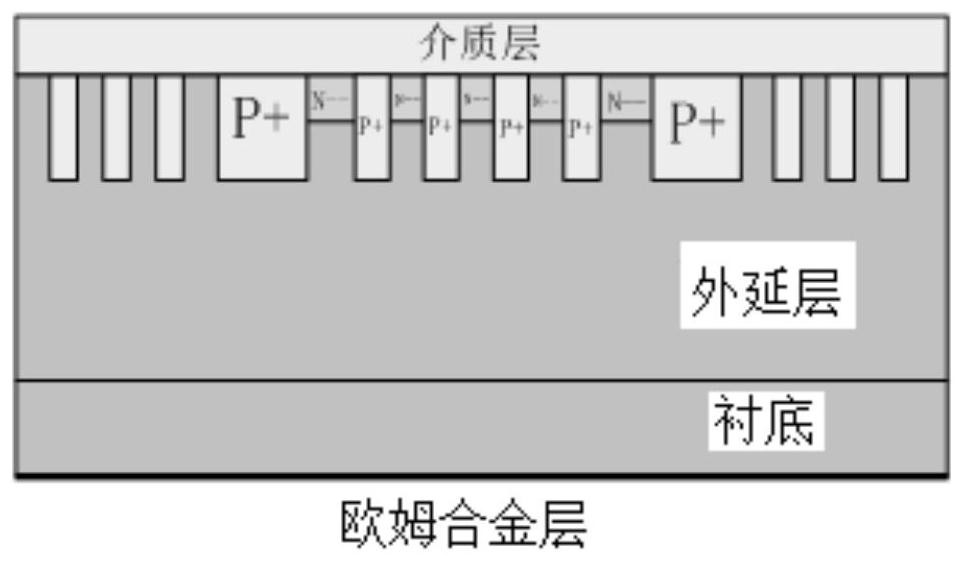

[0102] Such as Figure 1f As shown, the high barrier SiC JBS device provided in this embodiment includes a first electrode layer, a SiC substrate, an N-SiC epitaxial layer, a second electrode layer, a dielectric layer and a PI layer arranged from top to bottom.

[0103] Among them, the first electrode layer uses Ni as the SiC ohmic alloy layer, and the Ti / Ni / Ag back metal layer is thickened, with a thickness of 1.0um-1.2um; the thickness of the SiC substrate is 250um-350um; the N-SiC epitaxial layer The thickness is 6um-30um, which is doped with nitrogen ions and phosphorus ions, and the doping concentration is 1e15cm -3 -3e16cm -3 ; The second electrode layer is a Ti metal layer with a thickness of 150nm-200nm; the dielectric layer is SiO 2 The thickness of the layer is 0.8um-1.0um; the thickness of the PI layer is 10um-30um.

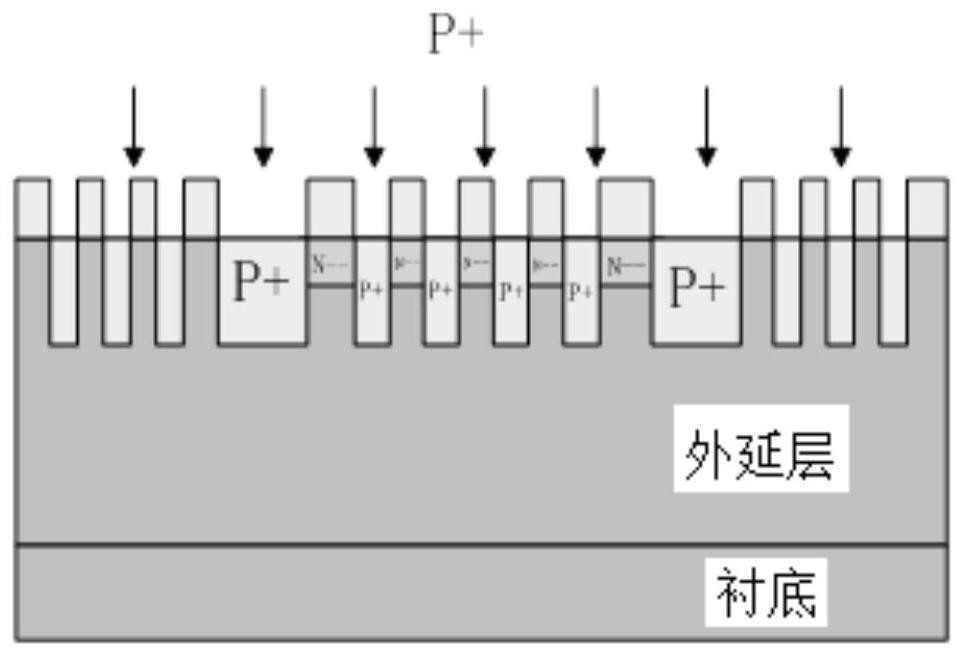

[0104] The N-SiC epitaxial layer includes a junction barrier region extending from the upper surface of the epitaxial layer into the epitaxial laye...

Embodiment 2

[0123] The structure of the high barrier SiC JBS device provided in this example is the same as that of Example 1, and its preparation method is as follows:

[0124] Step 1: providing a SiC substrate and an N-SiC epitaxial layer on the SiC substrate;

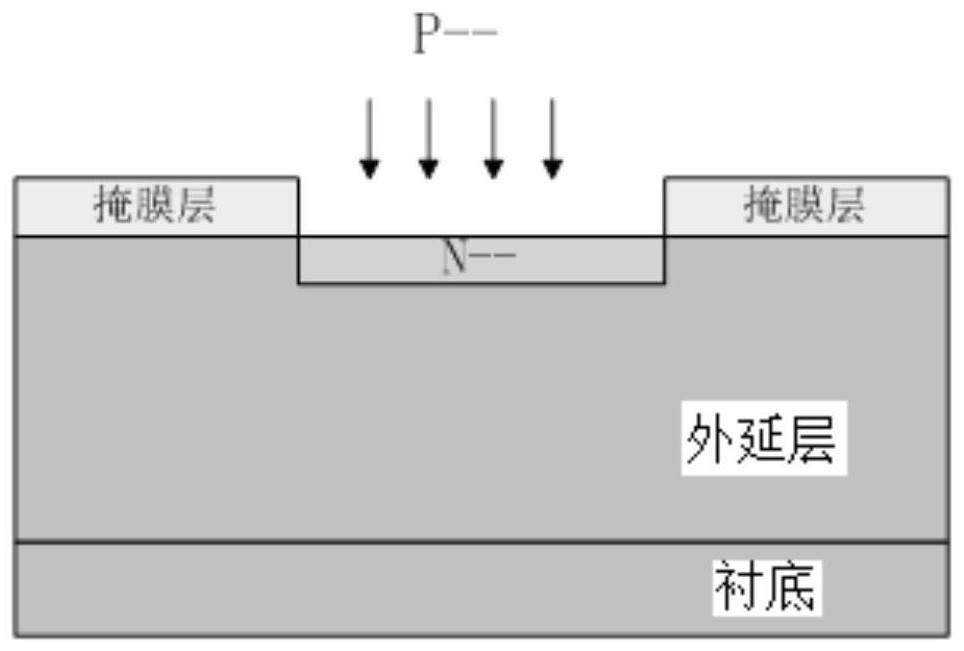

[0125] Step 2: forming a junction barrier region and a terminal region on the upper surface of the epitaxial layer:

[0126] (1) Cleaning the N-SiC wafer;

[0127] (2) An etching mask is grown on the surface of the SiC wafer, and a second mask is used to perform photolithography and etching to form a second implant mask, and a deep implantation of P-type impurities (P+ implantation) is performed on the etched area, The depth of injection is 1.0um, and the injection concentration is 1e19cm -3 -5e20cm -3 , forming a JBS structure;

[0128] (3) Remove the mask and clean the wafer;

[0129] (4) An etching mask is grown on the surface of the wafer in step (3), and the active region is photolithographically and etched using the f...

Embodiment 3

[0133] The structure of the high barrier SiC JBS device provided in this example is the same as that of Example 1, and its preparation method is as follows:

[0134] Step 1: providing a SiC substrate and an N-- / N-SiC epitaxial layer on the SiC substrate;

[0135] Step 2: forming a junction barrier region and a terminal region on the upper surface of the epitaxial layer:

[0136] (1) Clean the N-- / N-SiC wafer;

[0137] (2) Growing an etching mask on the surface of the SiC wafer, using the second mask plate, performing photolithography and etching to form a second implant mask, and performing deep implantation of P-type impurities (P+ implantation) into the etched area, The depth of injection is 1.0um, and the injection concentration is 1e19cm -3 -5e20cm -3 , forming a junction barrier region in the active region and forming a terminal region at the same time;

[0138] (3) Remove the mask, clean the wafer, and perform annealing treatment.

[0139] Step 3-6: Same as Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com