Solenoid type difference inductor based on silicon through hole

A differential inductance and through-silicon via technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as low occupied area and Q value of planar differential inductors, and can not fully meet the performance requirements of monolithic RF integrated chips. , to enhance the magnetic field coupling, reduce the size of the inductor, and improve the overall inductance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

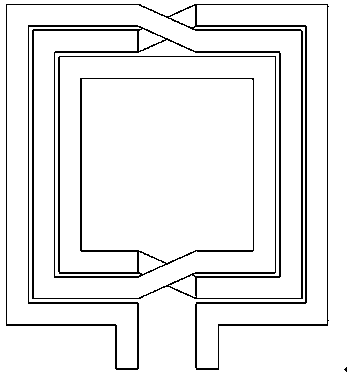

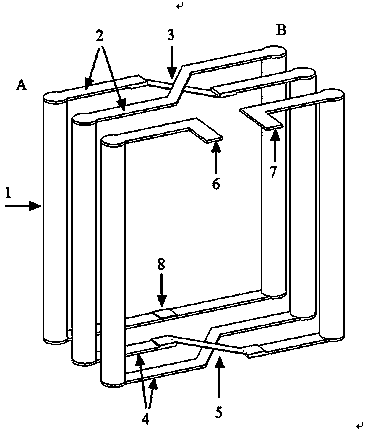

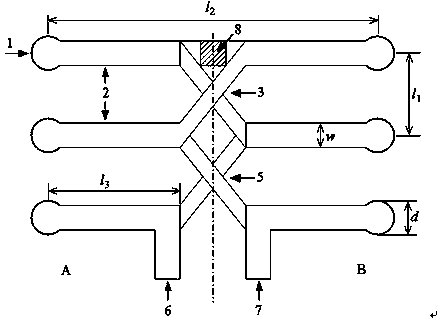

[0015] The technical solution provided by the present invention is: it is composed of horizontal metal lines in the top and bottom metal layers of the silicon substrate and through-silicon holes vertically penetrating the silicon substrate, using the via-first through-silicon hole process Firstly, metal vias are etched in the silicon interposer, and then horizontal interconnect lines are built on the top and back of the silicon interposer and electrically connected to the through silicon vias to form a coil. In order to realize a completely symmetrical structure, there are several groups of crossing wires on the metal lines in the horizontal direction, which are realized by using metal vias and two metal layers.

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] like figure 2 , 4 As shown, the differential inductor of the present invention includes metal lines in the top and bottom metal layers of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com