Integrated magnetic core framework of induction cooker and machining method of integrated magnetic core framework

A processing technology and technology of induction cooker, applied in the field of induction cooker, can solve the problems of increased labor cost, equipment cost and material cost, troublesome installation of wire plate and magnetic core of induction cooker, poor uniformity of induction heating, etc. The installation process and the effect of enhancing the magnetic field coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the magnetic circuit for induction heating of traditional induction cookers, the magnetic core is a plurality of separate rectangular monomers, which are installed in the groove of the engineering plastic skeleton. The installation and maintenance process is complicated, and the strength to withstand mechanical impact is poor. The magnetic circuit coupling between the pots is not tight enough. Due to the limitation of the structure and shape of the magnetic core, it is difficult to optimize the magnetic circuit of the traditional induction cooker.

[0024] In this embodiment, a microcrystalline alloy magnetic core material is selected, and the integrated die-casting process is adopted to manufacture an integrated induction cooker magnetic core skeleton in which the magnetic core and the skeleton are combined into one, and the outer surface of the magnetic core is encapsulated with epoxy resin.

[0025] The microcrystalline alloy utilizes ultra-rapid cooling and solid...

Embodiment 2

[0029] The design of the magnetic circuit of the traditional induction cooker is limited by the shape of the magnetic core, the structure is simple, the leakage of the magnetic field is relatively large, and the uniformity of the induction heating is not good. The areas at the center of the bottom and the outer edges of the pan are cooler.

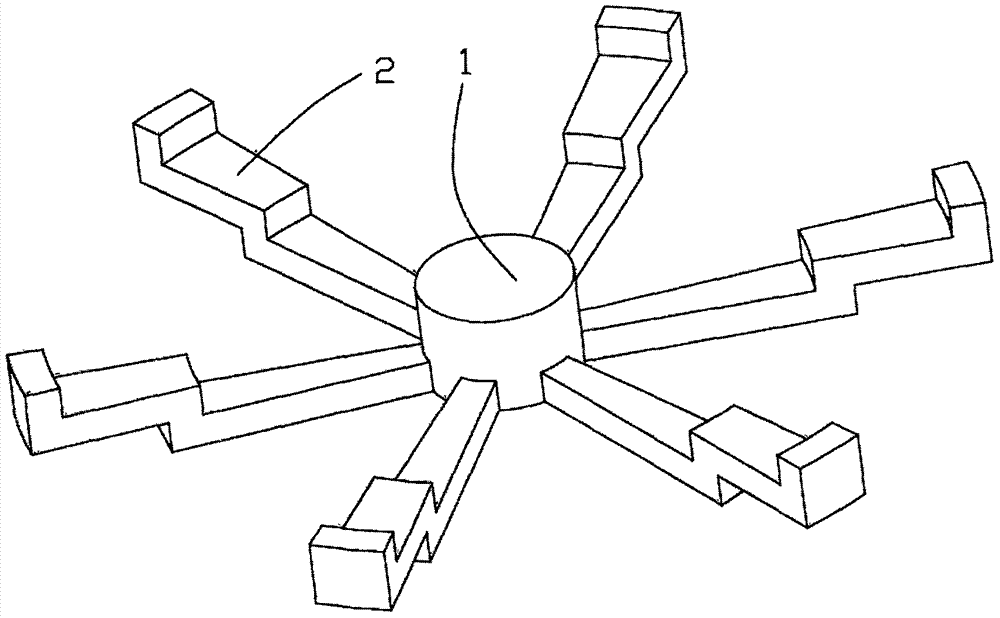

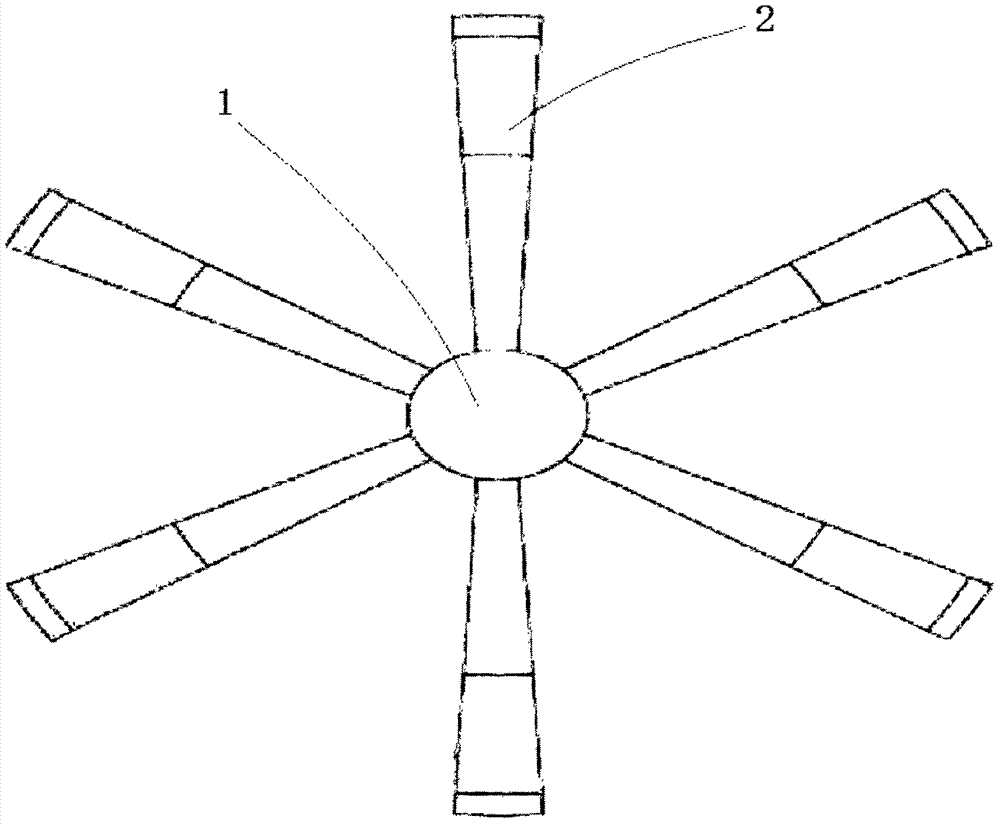

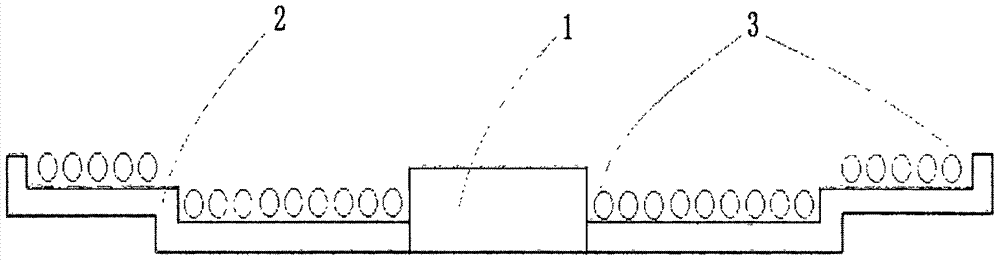

[0030] This embodiment adopts the optimized design of the skeleton structure of the integrated induction cooker magnetic core, which includes two major parts, a central cylinder 1 and a plurality of fan-shaped parts 2 uniformly distributed along the outer surface of the central cylinder. The fan-shaped portion 2 is a stepped structure rising from the inside to the outside, and the step surface of the ladder extends outward and upward in three stages along the bottom surface of the central column. The stepped fan-shaped magnetic core structure can reduce the distance between the coil plate and the pot body, strengthen the coupling of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com