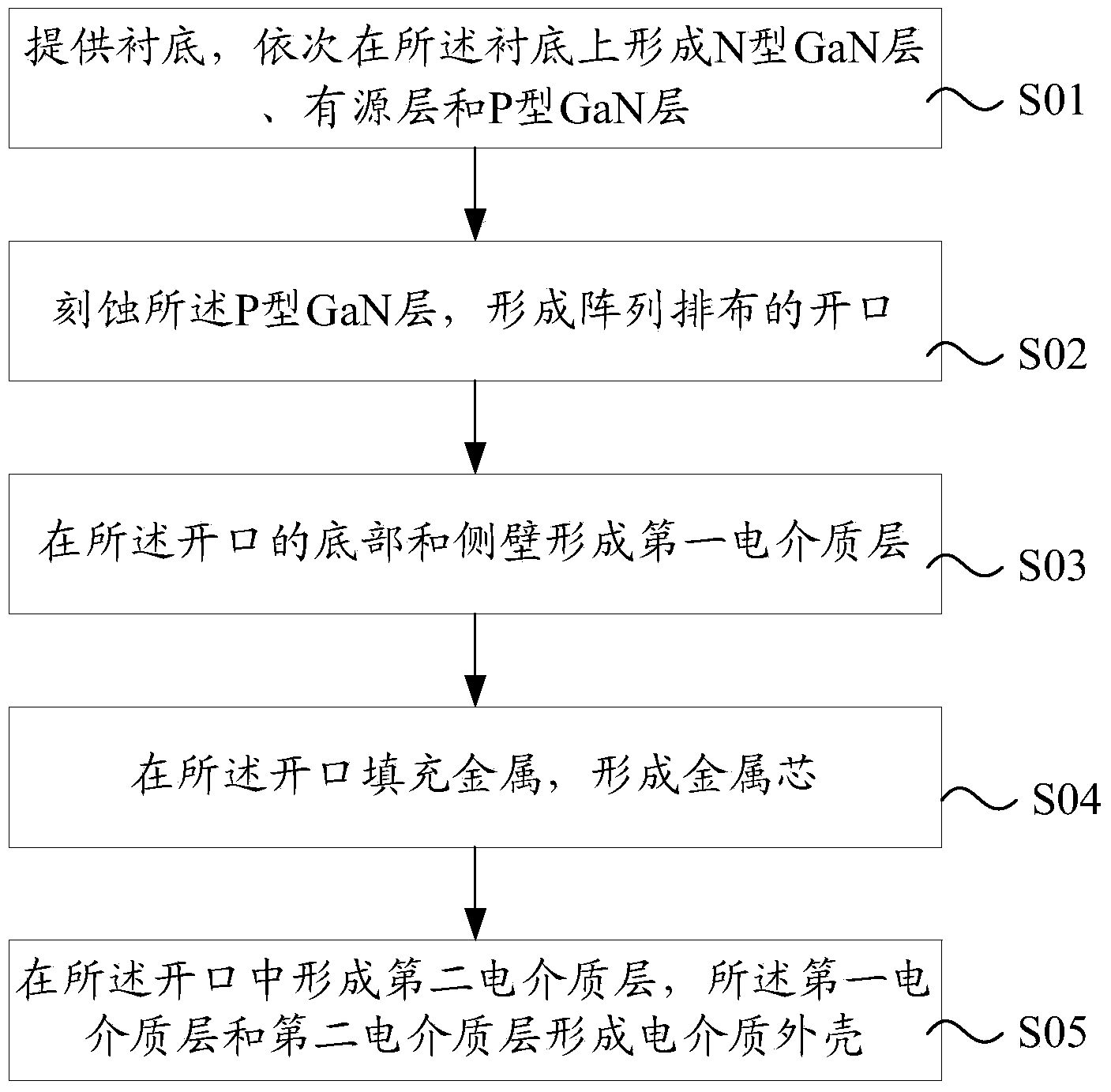

LED (Light Emitting Diode) chip and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

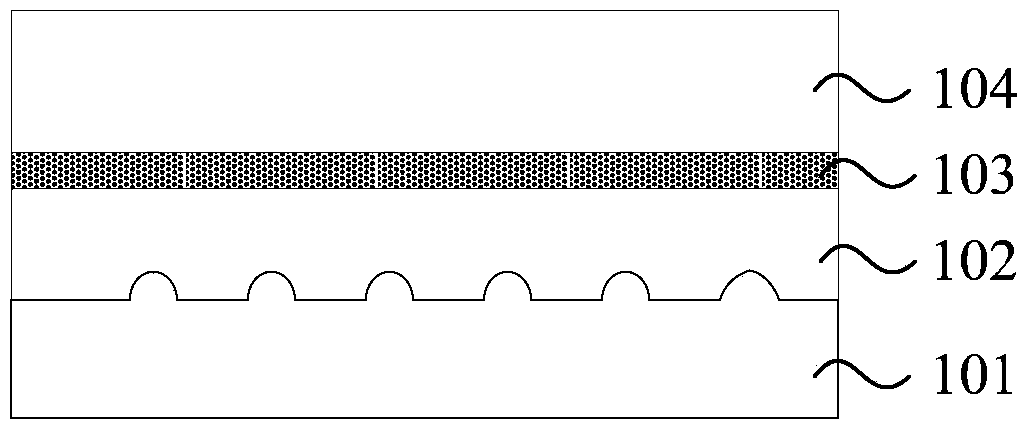

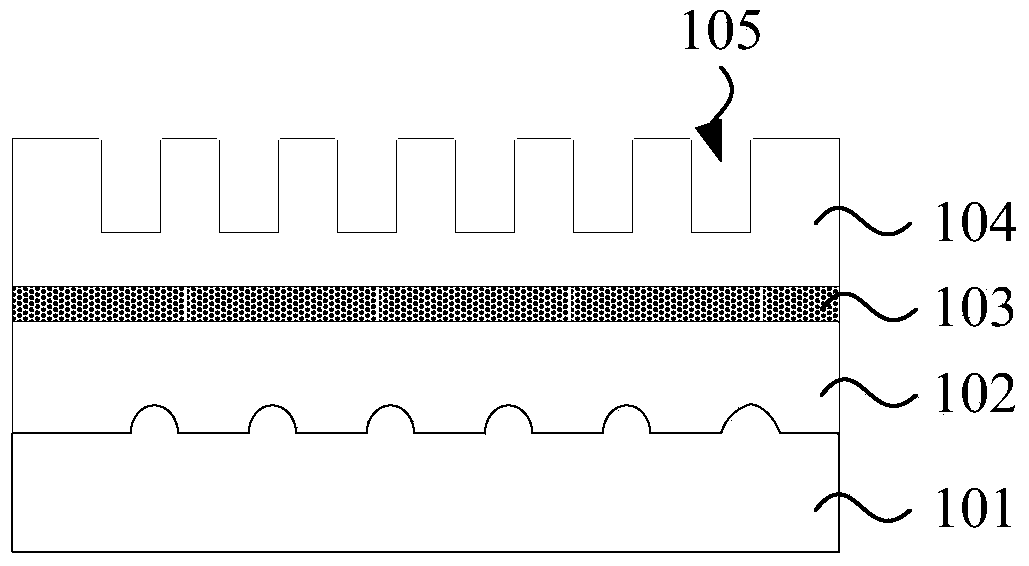

[0034] As mentioned in the background art, improving the luminous efficiency of LED chips is a direction of continuous exploration and improvement in the industry.

[0035] For this reason, the present invention provides a kind of LED chip and its manufacturing method, described LED chip is formed with metal nano-array in P-type GaN layer, and described metal nano-array comprises metal core and dielectric shell, can improve the internal quantum efficiency of LED And light extraction rate, thereby improving the luminous efficiency of LED.

[0036] The present invention will be described in more detail below with reference to the accompanying drawings, wherein preferred embodiments of the present invention are shown, it should be understood that those skilled in the art can modify the present invention described herein and still achieve the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those ski...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com