Machine for scraping kelp roots on seedling rope

A technology of kelp root and seedling rope, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high cost, environmental pollution, huge human and material resources, etc., and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

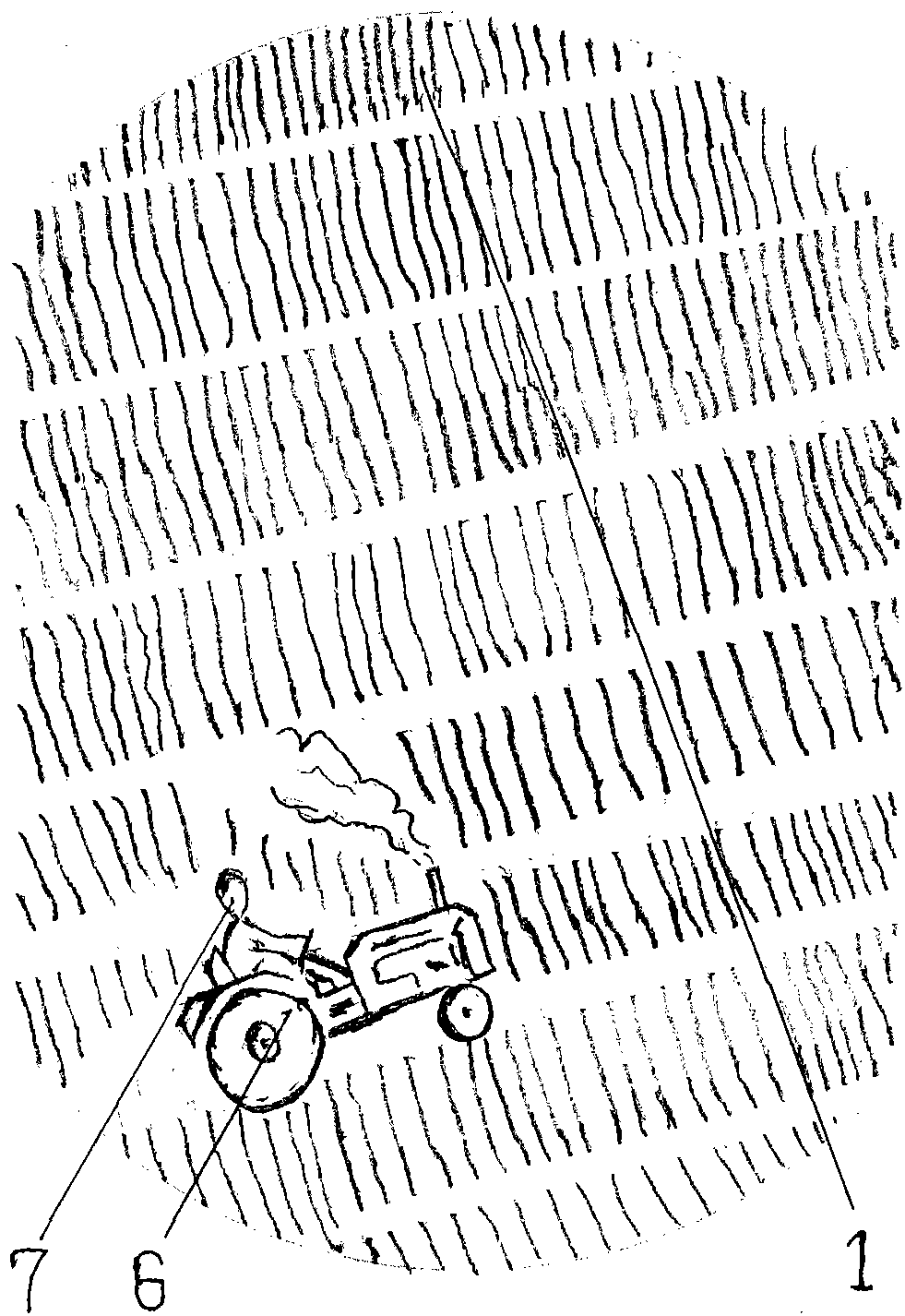

[0038] Based on practical experience, design and draw drawings, and then entrust professional manufacturers of machinery manufacturing to mass-produce steel frames and scrapers in accordance with standardized requirements.

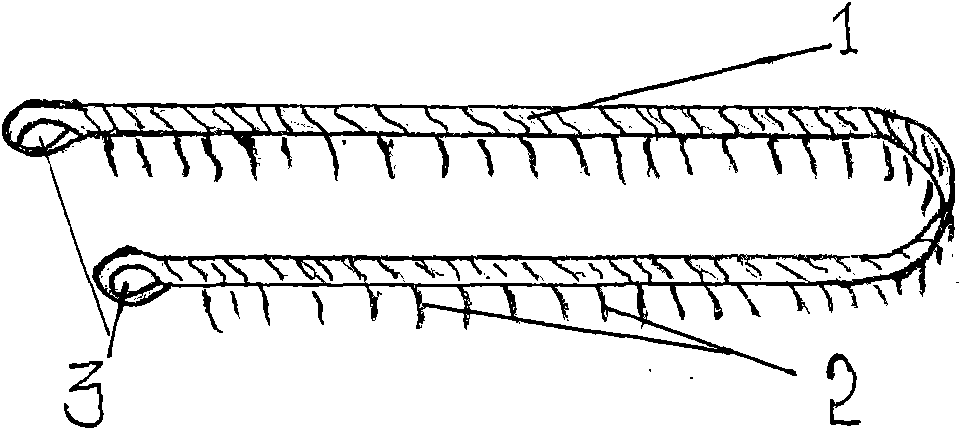

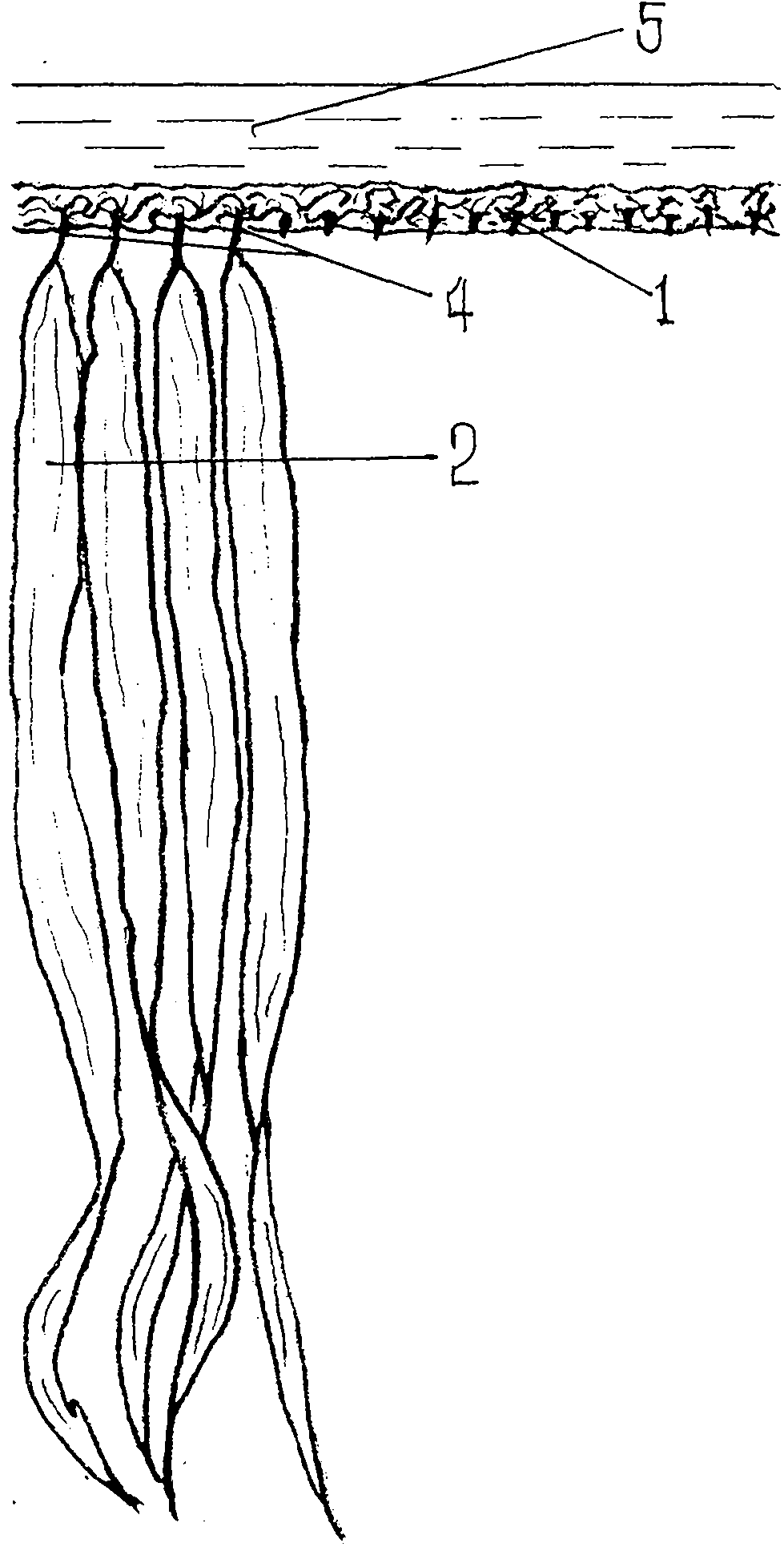

[0039] The steel frame body is made of square tube, round tube or angle steel material, the outer diameter of the tube specification is within 100mm, and the side length of the angle steel is within 100mm. When making the frame, it is necessary to weld the auxiliary support body to ensure its firmness; and set the fixing bolt holes, and use the bolt fixing method to install the carrier; Figure 5 Among them 1, Figure 7 1 of them.

[0040] The whole scraper is divided into two parts, the upper part and the lower part, which are manufactured independently, and then connected by a bolt as a movable fixation. There should be room for rotation when the bolt is buckled up, so that the upper and lower parts can move freely. Two bolt holes are arranged on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com