Cylinder type centrifugal extractor

A centrifugal extractor and cylindrical technology, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problem of obvious vibration of the centrifugal extractor, affecting the processing flux and efficiency of the centrifugal extractor, and the short residence time of the heavy phase, which cannot be separated well, etc. problems, to achieve good extraction and separation effects, small phase entrainment, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

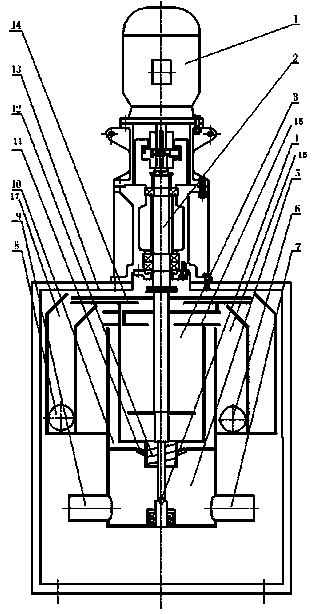

[0023] like figure 1 As shown, the cylindrical centrifugal extractor includes motor 1, transmission system 2, drum 3, auxiliary support 4, mixing chamber 5, light phase outlet 6, light phase inlet 7, heavy phase outlet 8, heavy phase Phase inlet 9, interlayer 10, annular impeller 11, feed impeller 12, frame 13, light phase weir plate 15, heavy phase weir plate 14, light phase collection chamber 16 and heavy phase collection chamber 17;

[0024] One end of the transmission system 2 is connected to the motor 1, and the other end of the transmission system 2 is connected to the top of the rotating shaft of the drum 3. The bottom of the rotating shaft of the rotating drum 3 is provided with an auxiliary support 4, and the lower part of the rotating drum 3 is provided with a stopper. A flow plate, a feed impeller 12 is provided below the center position of the bottom of the drum 3, a mixing chamber 5 is provided below the drum 3, mixing baffles are provided on the periphery and bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com