Manufacturing method of equidensite elastomer sound insulation material in different thickness for vehicle

A manufacturing method and equal-density technology, applied in the field of automobile material manufacturing, can solve problems such as unfavorable automobile lightweight goals, waste of material resources, inability to realize processing, etc., and achieve low material cost, good sound insulation effect and good physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A car front wall sound insulation product is arranged on the inner side of the car front wall, is a composite structure, is made of PUR foam and an elastic body sound insulation material, and the manufacturing method of the elastic body sound insulation material comprises the following steps:

[0029] (1) Weighing and mixing: After weighing the polyolefin elastomer, PE, barite powder and extender oil according to the ratio of 70:30:280:20, put them into the internal mixer for high-speed kneading, and exhaust once in the middle. After mixing for 6 minutes, the temperature reaches 130°C and then the rubber is removed.

[0030] (2) Rubber mixing: Put the above-mentioned rubber materials on the open mill and turn them evenly. The roller heating temperature is 120°C.

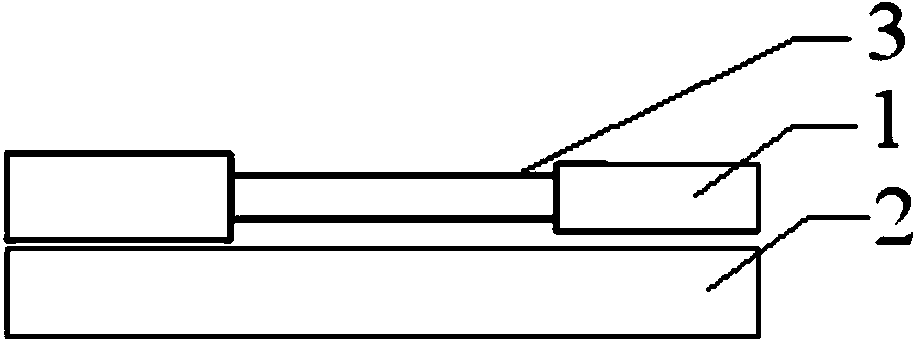

[0031] (3) Extrusion into sheets: put the above-mentioned rubber into the calender, and extrude into sheets through embossing rollers. The structure of the embossing rollers used is as follows: figure 1 As s...

Embodiment 2

[0036] A method for manufacturing an elastic body sound insulation material with equal density and different thickness for vehicles, the following steps are adopted:

[0037] (1) Raw material preparation: weigh polyolefin elastomer, PE, barite powder and industrial grade white mineral oil in a weight ratio of 80:20:290:10;

[0038] (2) Mixing: Put the above-mentioned raw materials into a banbury mixer for high-speed kneading. The time for the raw materials to be mixed in the banbury mixer is controlled at 5 minutes, and the temperature at the bottom of the mixing tank in the banbury mixer is controlled at 150°C. The temperature is controlled at 125°C during the debinding of the mill, and the exhaust is exhausted once in the middle to obtain the first rubber material;

[0039] (3) Rubber mixing: the first rubber material is placed on the open mill and covered with rollers to turn over evenly, and the roller heating temperature of the open mill is 110 ° C to obtain the second ru...

Embodiment 3

[0044] A method for manufacturing an elastic body sound insulation material with equal density and different thickness for vehicles, the following steps are adopted:

[0045] (1) Material preparation: weigh polyolefin elastomer, PE, barite powder and industrial grade white mineral oil in a weight ratio of 75:25:280:20;

[0046] (2) Mixing: Put the above-mentioned raw materials into a banbury mixer for high-speed kneading. The time for the raw materials to be mixed in the banbury mixer is controlled at 7 minutes, and the temperature at the bottom of the mixing tank in the banbury mixer is controlled at 170°C. The temperature is controlled at 135°C during the debinding of the mill, and the exhaust is exhausted twice in the middle to obtain the first rubber material;

[0047] (3) Rubber mixing: the first rubber material is placed on the open mill and covered with rollers to turn over evenly, and the roller heating temperature of the open mill is 130 ° C to obtain the second rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com