Novel tertiary air gate valve plate of dry process cement rotary kiln

A dry process cement and rotary kiln technology, applied in sliding valves, valve devices, rotary drum furnaces, etc., can solve the problems of skeleton deformation and jamming, large pieces of castable peeling off, inconvenient system operation and adjustment, etc., to achieve high quality, overall simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

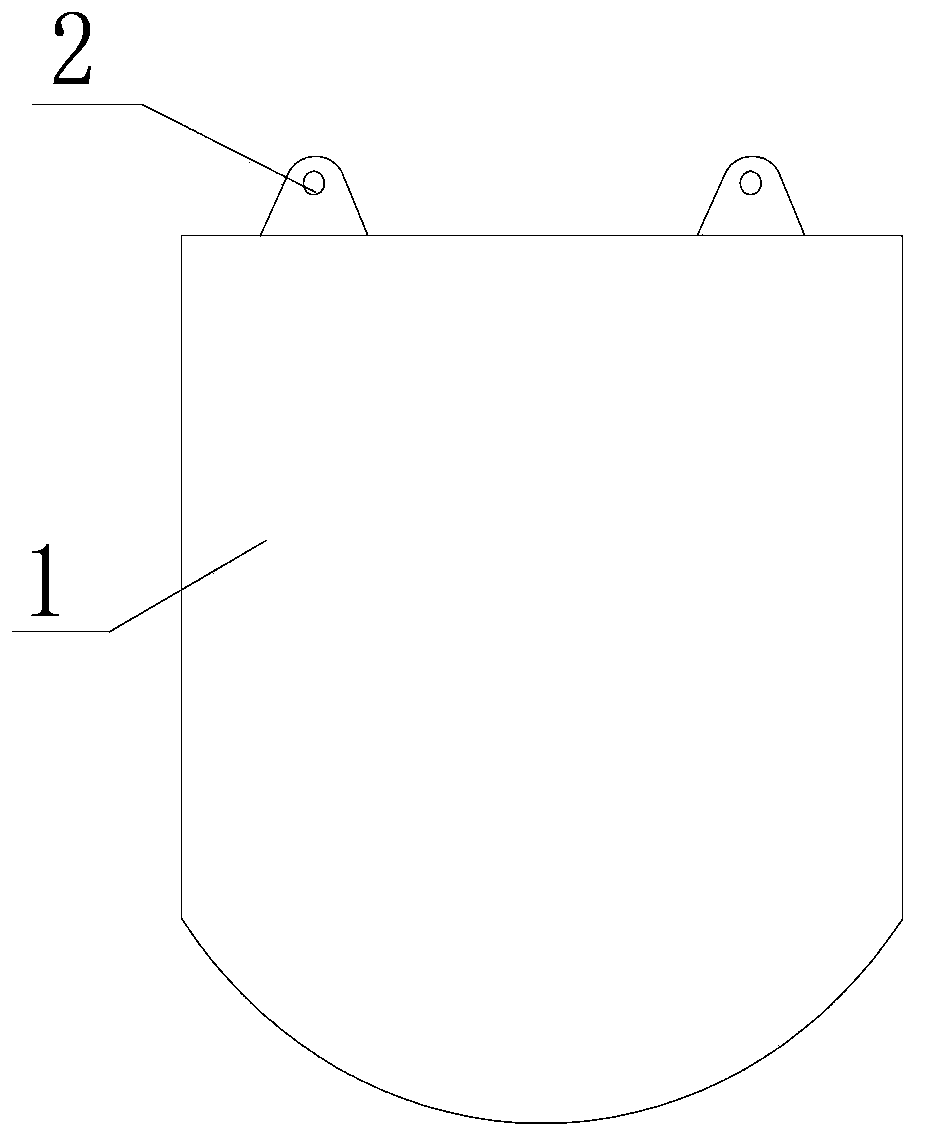

[0016] Such as figure 1 As shown, a new dry-process cement rotary kiln tertiary damper valve plate according to the present invention includes a valve plate body 1, and the cross section of the valve plate body 1 is composed of four sides, three of which are straight lines, and the other side It is an arc, and the lifting lug 2 is provided on the straight line opposite to the arc. The valve plate body 1 is made of corundum mullite castable; the valve plate body 1 is integrally formed; the lifting lugs 2 are in pairs Setting; the height of the valve plate body 1 is between 1.5-3m; the width of the valve plate body 1 is between 1-2.5m; the thickness of the valve plate body 1 is between 150-350mm. The overall structure of the invention is simple, after baking, the inner and outer materials of the valve plate are tightly wrapped, and will not peel off or b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com