Double vacuum inner condensing solar collector tube for power generation and heating

A solar collector tube and vacuum tube technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of narrow energy utilization range, heat waste of solar water heaters, etc., to expand the energy utilization range, avoid heat waste, The effect of improving the comprehensive utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

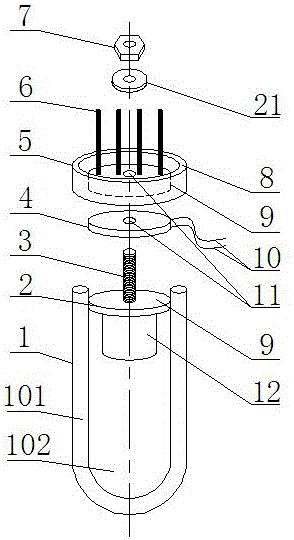

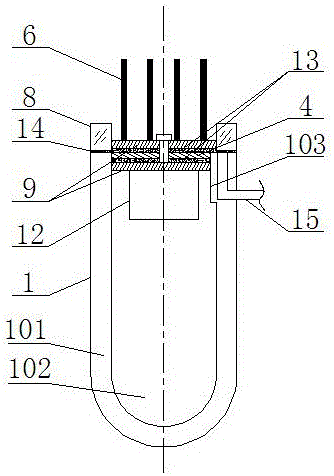

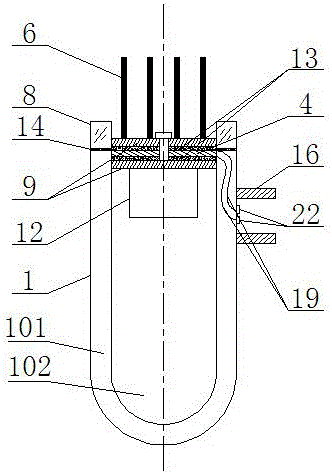

[0021] Such as figure 1 and Figure 5 As shown, the double-vacuum inner condensing type power generation and heating solar collector tube includes a vacuum tube 1 arranged below the header 20 of the solar water heater. One end of the vacuum tube 1 is closed, the other end is provided with an opening, and the tube wall is provided with There is a closed vacuum interlayer 101. The open end of the vacuum tube 1 is provided with a heat dissipation end 5 nested at the bottom of the header 20. The open end of the vacuum tube 1 is provided with a thermoelectric power generation sheet 4 and a thermoelectric power generation sheet 4 in turn. The metal condensing end 2 below, the outer edge of the metal condensing end 2 is welded and connected to the inner wall of the vacuum tube 1, so that a closed vacuum chamber 102 is formed in the vacuum tube 1, and the end of the metal tube condensing end 2 extends into the vacuum tube 1 Inside and not in contact with its inner wall, the two outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com