Refrigerator with heat preservation drying mechanism

A refrigerator and drying technology, which is applied in the direction of household refrigerators, coolers, household appliances, etc., can solve the problems such as the adverse effect of the environmental humidity drying oven on the drying and sterilization effect, the reduction of waste heat utilization, and the unstable temperature of the incubator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

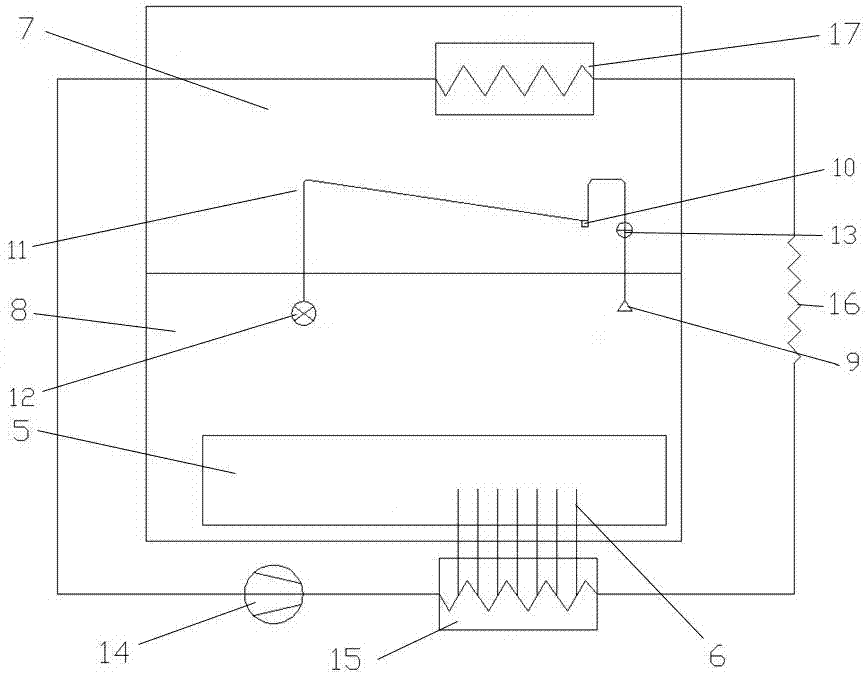

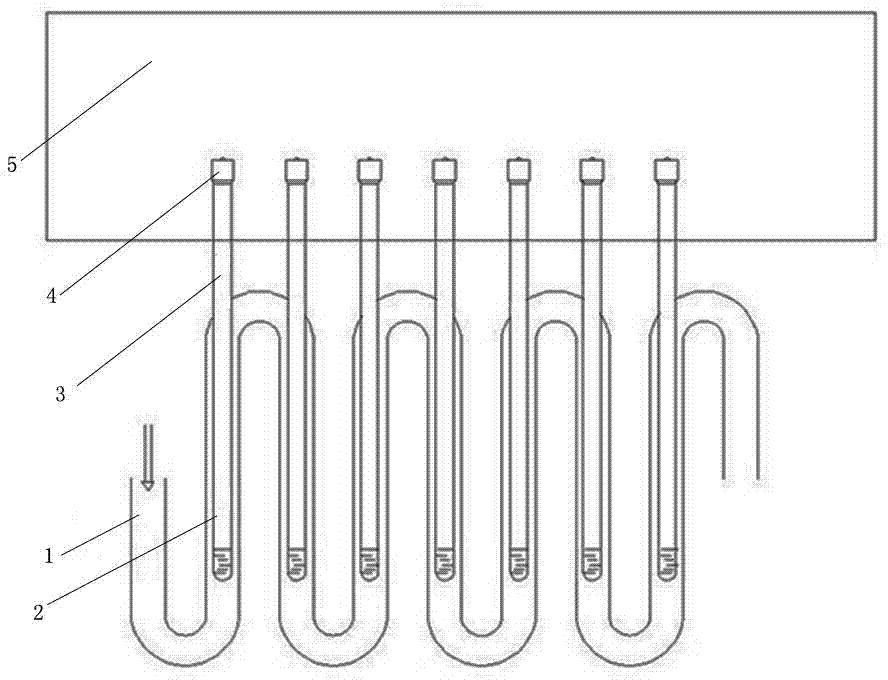

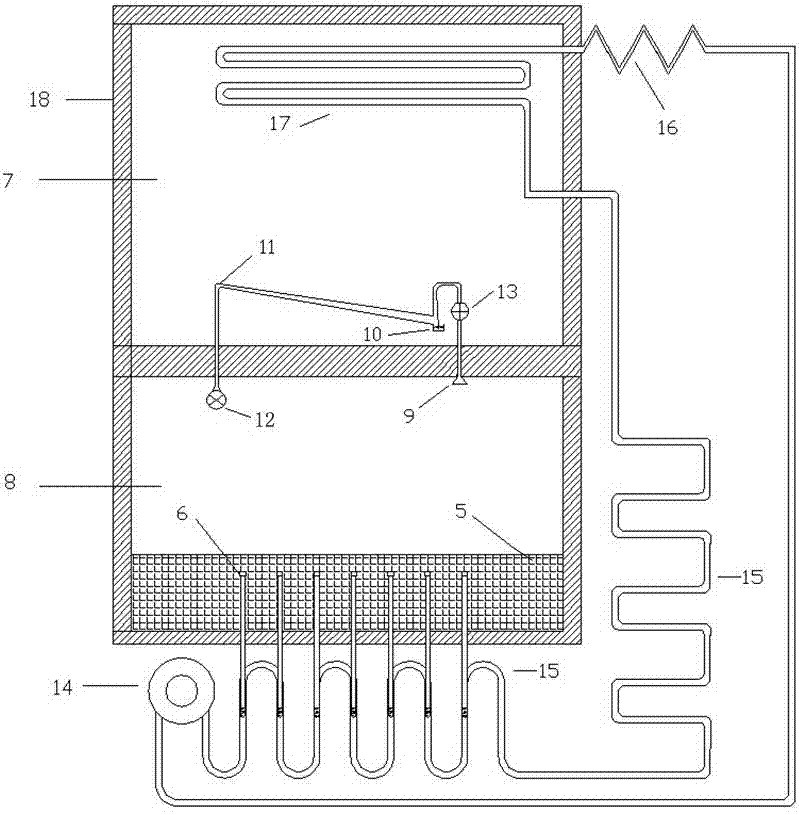

[0021] see figure 1 , The refrigerator with heat preservation and drying mechanism includes freezing and refrigerating chamber 7 and refrigeration mechanism. Refrigerating mechanism comprises evaporator 17, capillary tube 16, compressor 14 and condenser 15, and evaporator 17 is positioned at freezing and refrigerating compartment 7, and capillary tube 16, compressor 14 and condenser 15 are all positioned at the outside of freezing and refrigerating compartment 7. A heat preservation chamber 8 is provided at the bottom outside the freezer and refrigerator compartment 7 . The bottom of the heat preservation chamber 8 is equipped with a phase change heat storage block 5. The material of the phase change heat storage block is a shape-fixed phase change material. The research on shape-set phase change materials has been relatively mature in the field where the phase change temperature is about 40-50°C. Various options are available. The research results of the Ministry of Science...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com