Target displacement vector measuring device and method based on laser tracker point-by-point calibration

A technology of laser tracker and target displacement, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low accuracy of measurement results, and achieve the effect of improving detection accuracy, solving detection problems, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

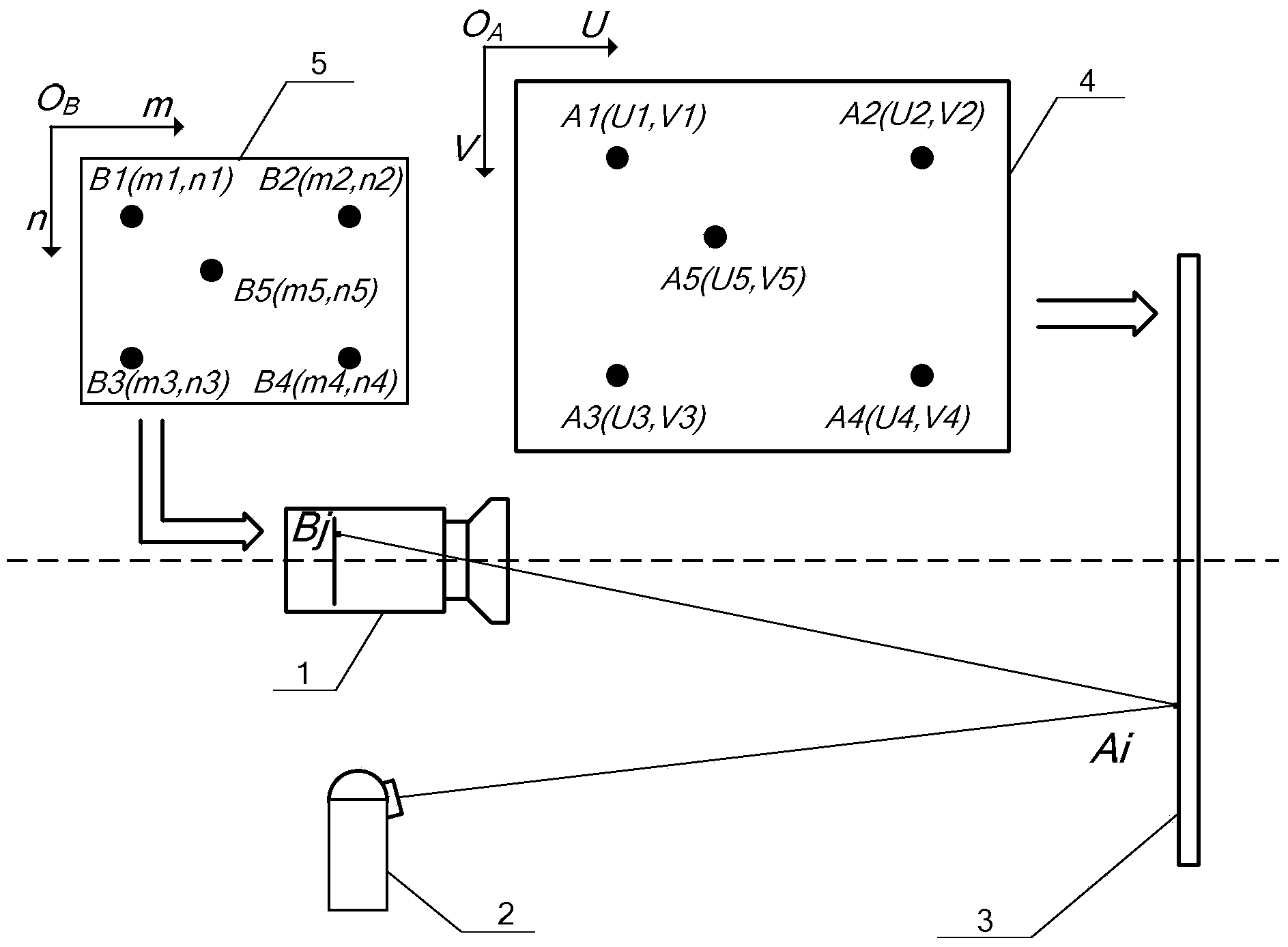

[0047] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the target displacement vector measuring device based on laser tracker point-by-point calibration described in this embodiment, it comprises high-speed CCD camera 1, laser tracker 2 and diffuse reflection projection screen 3, target object is on diffuse reflection projection screen 3 move up;

[0048] The high-speed CCD camera 1 is used to image the target marking point on the diffuse reflection projection screen 3 , and the laser tracker 2 is used to measure the coordinates of the target marking point on the diffuse reflection projection screen 3 .

[0049] In this embodiment, the spatial ranging range of the laser tracker 2 is not less than 50m, the angle measuring range is better than 100° in the vertical direction, better than 180° in the horizontal direction, and the positioning accuracy is better than 20μm+5μm / m.

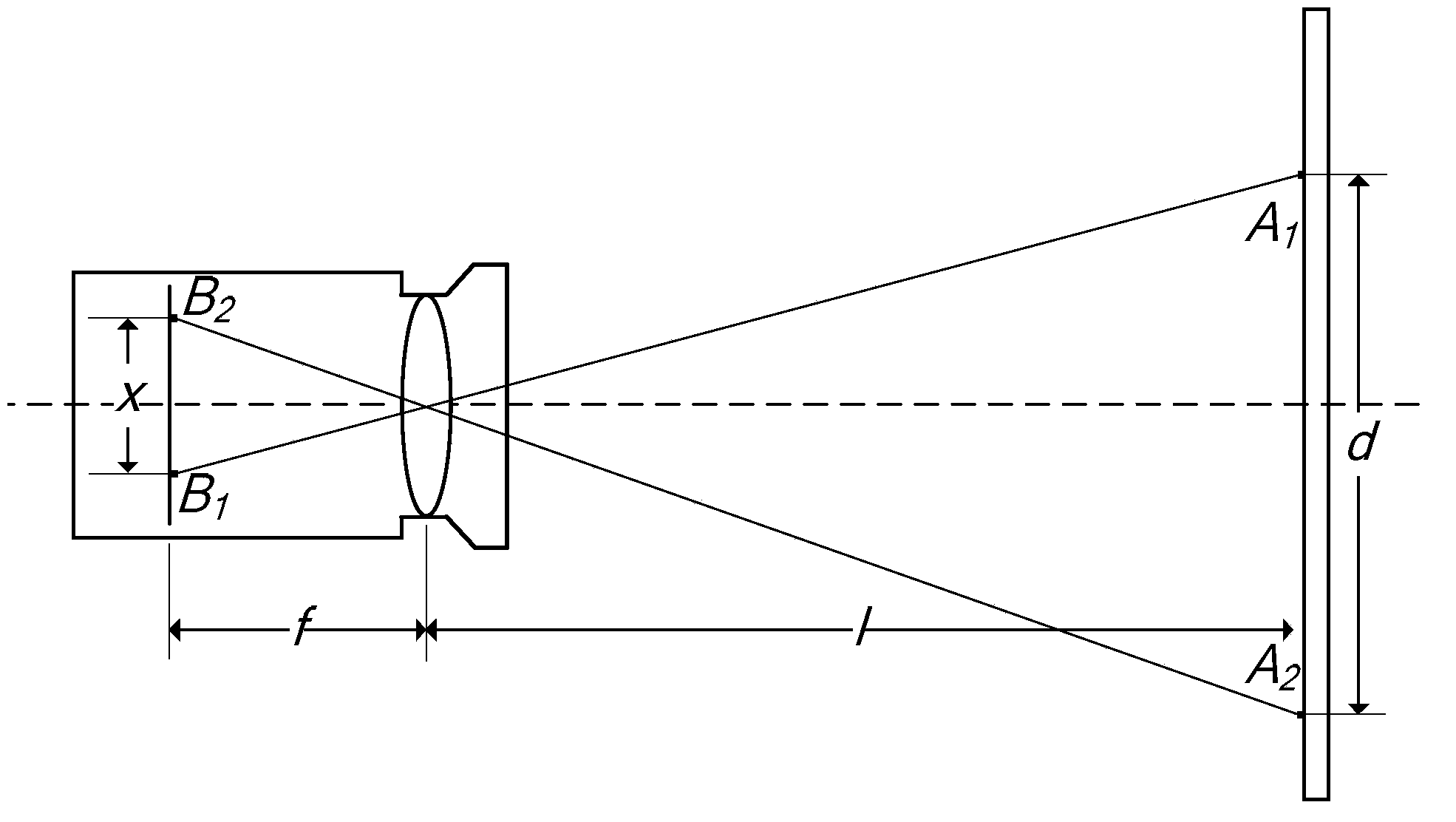

[0050] The lens focal length of the high-speed CCD cam...

specific Embodiment approach 2

[0052] Specific Embodiment 2: This embodiment will further explain Embodiment 1. The diffuse reflection projection screen 3 in this embodiment is a square formed by splicing two pieces of 1000mm×500mm×3mm frosted glass. The diffuse reflection projection screen 3 Spray black paint on the back.

[0053] In this embodiment, the diffuse reflection projection screen 3 has a surface area of 1m×1m, and the black paint on its back is used to eliminate secondary reflection. The flatness of the frosted glass is required to be better than 0.2mm, the joint between two pieces of frosted glass is less than 0.5mm, the overall flatness of the diffuse reflection projection screen 3 is better than 0.5mm, and the verticality to the ground is better than 0.1°.

specific Embodiment approach 3

[0054] Specific implementation mode three: the following combination figure 1 Describe this embodiment, the measurement method based on the above-mentioned target displacement vector measuring device based on laser tracker point-by-point calibration described in this embodiment, it includes the following steps:

[0055] Step 1: Set a point A1 on the diffuse reflection projection screen 3 as the target calibration point, and the coordinate value of the target calibration point A1 on the projection screen coordinate system 4 obtained by the laser tracker 2 is A1 (U1, V1);

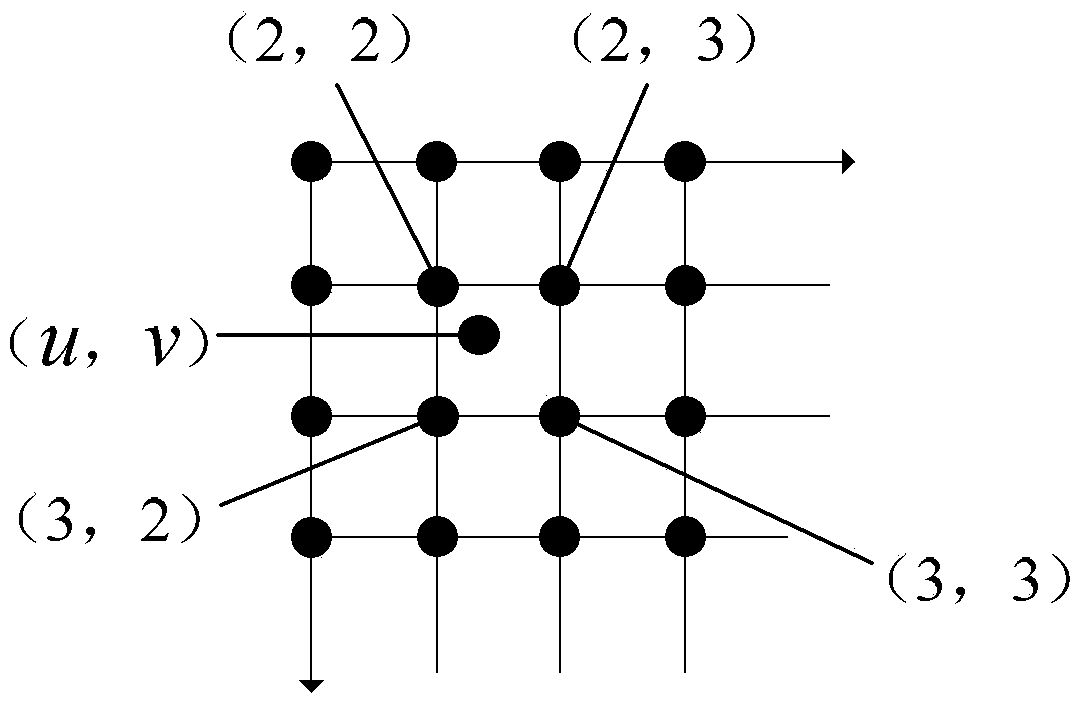

[0056] Step 2: keep the target calibration point A1 fixed, use the high-speed CCD camera 1 to image the target calibration point A1, obtain the corresponding conjugate point B1 of the target calibration point A1 on the image plane of the high-speed CCD camera 1, and use the high-speed CCD camera 1 to obtain the corresponding conjugate point B1 of the target calibration point A1. After the image processing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com