Dynamic driving system adopting servo force

A technology of drive system and servo drive, which is applied in the testing of measuring devices, instruments, and mechanical components, etc., can solve the problems of low precision of dynamic output force, poor ability of PID control to resist external interference, etc., and achieve compact structure, small volume, The effect of dynamic high-precision loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

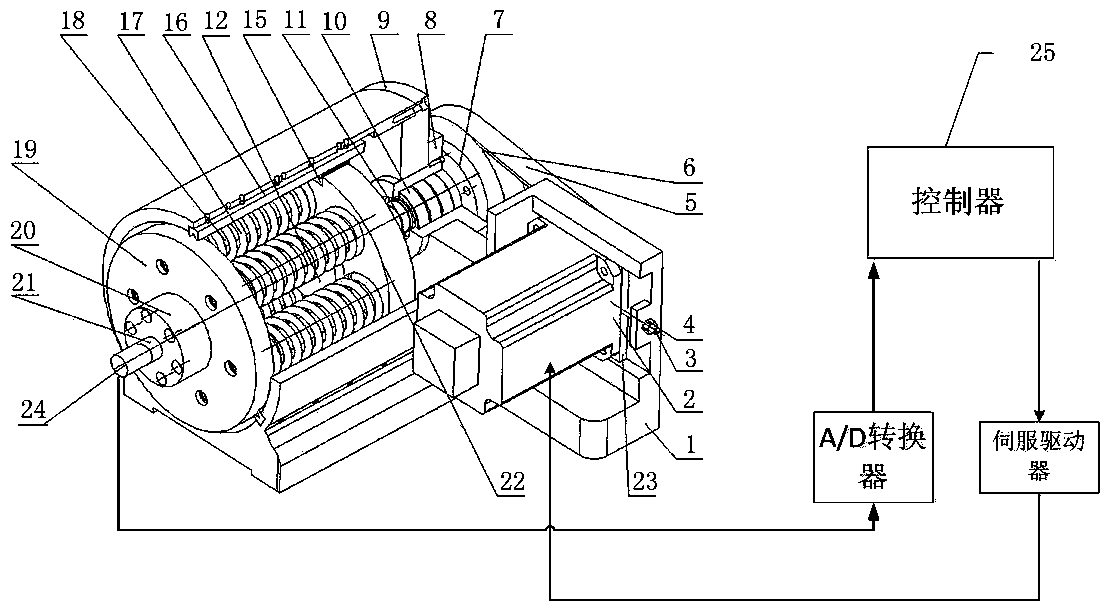

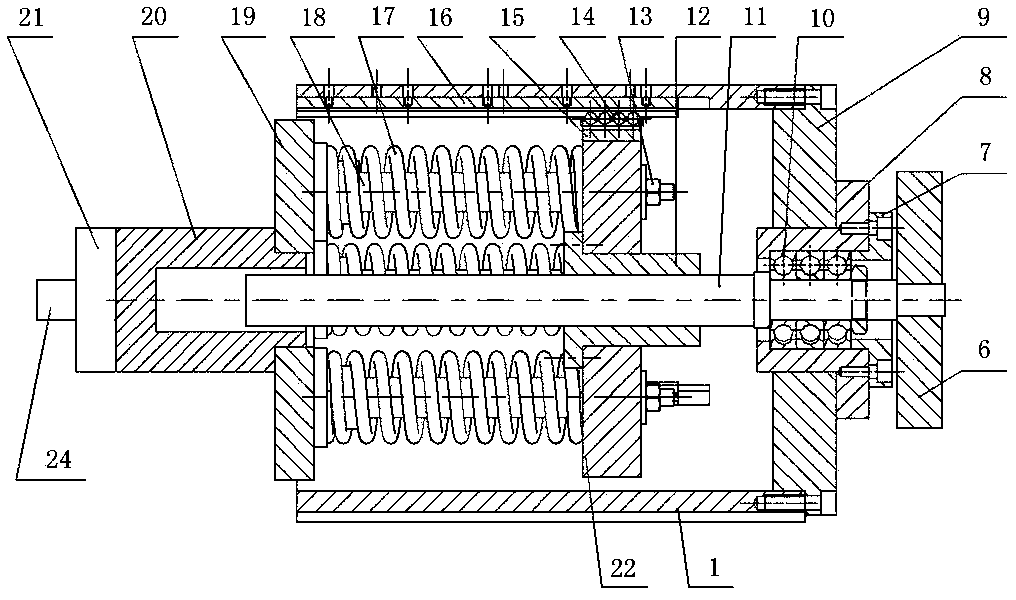

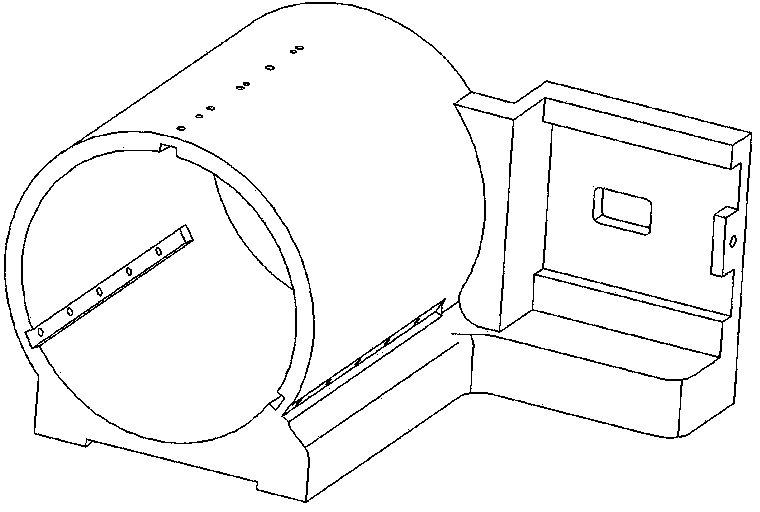

[0033] figure 1 It is a structural schematic diagram of the mechanical body in the present invention, figure 2 It is a sectional view of the mechanical body part in the present invention, image 3 Schematic diagram of the base structure of the mechanical body part in the present invention, Figure 4 It is a structural schematic diagram of the front loading disk of the mechanical body part in the present invention, Figure 5 It is a structural schematic diagram of the guide rod of the machine body part in the present invention. Figure 6 It is a system block diagram of the present invention, Figure 7 It is the dynamic force servo drive system of the present invention under the sinusoidal reference force, without the adaptive sliding mode control response curve and the tracking error curve of the disturbance observer, Figure 8 It is the dynamic servo driving force system of the present invention under the sinusoidal reference force, the adaptive sliding mode control respo...

Embodiment 2

[0064] The structure of this embodiment is the same as that of Embodiment 1, the difference is that: the driving method of the ball screw can be directly driven by the servo motor through the coupling and the ball screw. The ball screw can be realized by adopting a trapezoidal screw and a nut pair. A guide key can be used between the rear loading plate and the support to replace the rolling element assembly. The bearing set is a bearing set containing thrust ball bearings or cylindrical roller thrust bearings. The controller adopts single-chip microcomputer, DSP processor or industrial control computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com