Preparation method of tiny graph

A graphics and tiny technology, which is applied in the field of micro graphics preparation, can solve the problems of difficulty in making small-scale graphics and complicated processes, and achieve the effect of simple micro graphics preparation technology and large-area production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

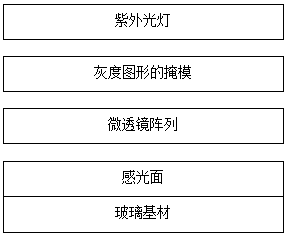

[0028] (1) Coating the photosensitive surface on the surface of the glass substrate;

[0029] (2) A microlens array is placed above the substrate coated with the photosensitive surface

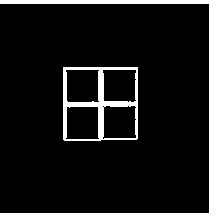

[0030] (3) Set the mask of the grayscale pattern above the microlens array such as figure 2 ;

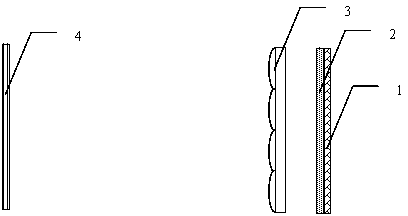

[0031] (4) An ultraviolet lamp is set above the mask pattern as an exposure light source for the mask pattern. The whole exposure system such as image 3 As shown, 1 in the figure represents the glass substrate, 2 represents the photosensitive surface, 3 represents the microlens array, and 4 represents the mask;

[0032] (5) Turn on the ultraviolet light source to perform reduced projection exposure on the mask pattern to realize nested lithography on the photosensitive surface.

[0033] (6) Take out the substrate and develop it to obtain the required tiny structure; Figure 4 As shown, 1 in the figure represents the glass substrate, and 2 represents the tiny structure of the corresponding mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com