Manufacturing method of inductor unit

A manufacturing method and sensor technology, which are used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of increased manufacturing difficulty, easy falling off or displacement, and overflowing glue, etc., to ensure reliability, low Crosstalk interference, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

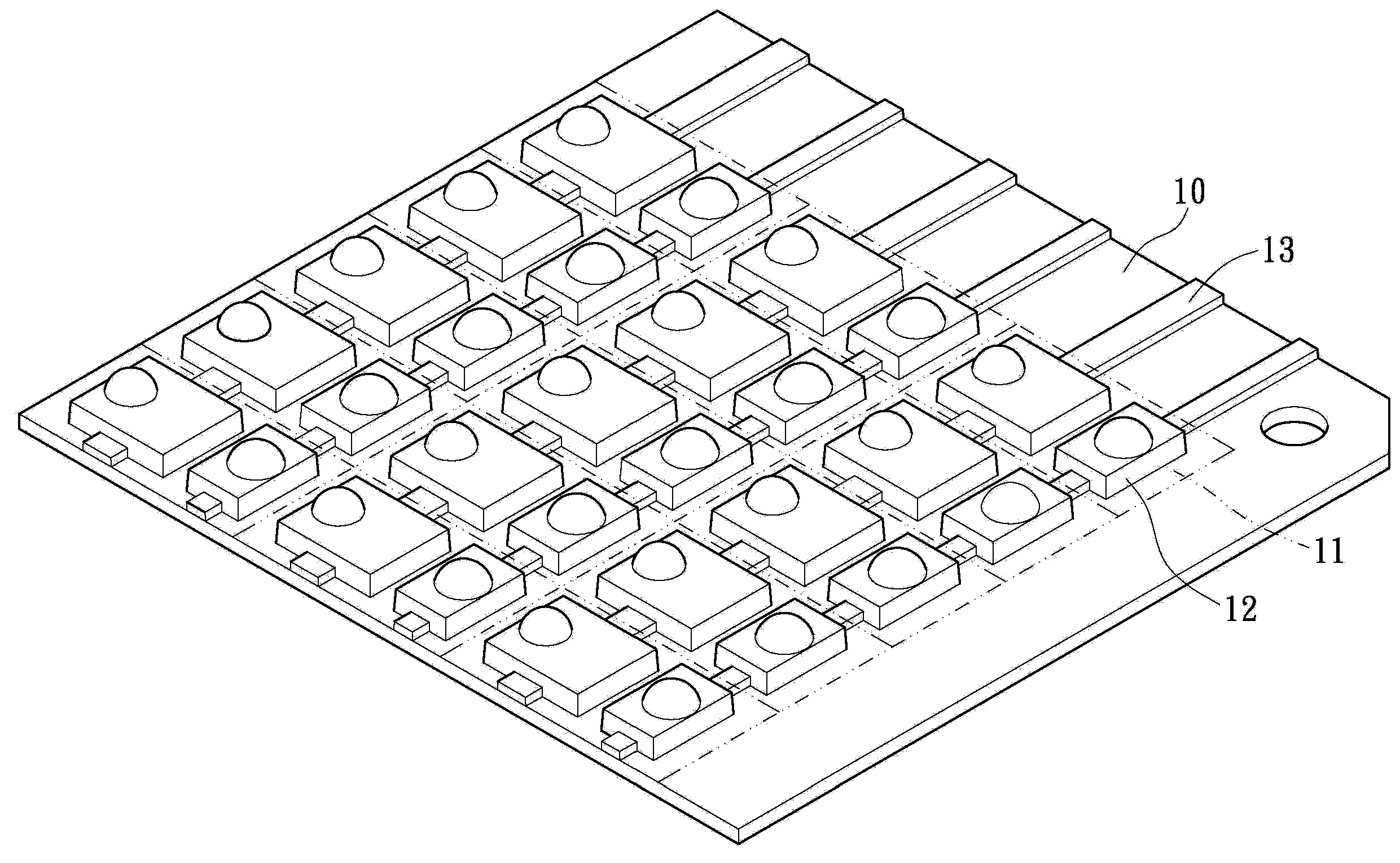

[0038] The present invention provides a method for manufacturing an inductor unit. The manufacturing method is to achieve the packaging and isolation of the components of the inductor unit by two-time molding and making use of the packaging top plate, which has the effect of reducing the manufacturing cost. It can also solve the shortcomings of traditional assembly methods. The manufacturing method includes the following steps:

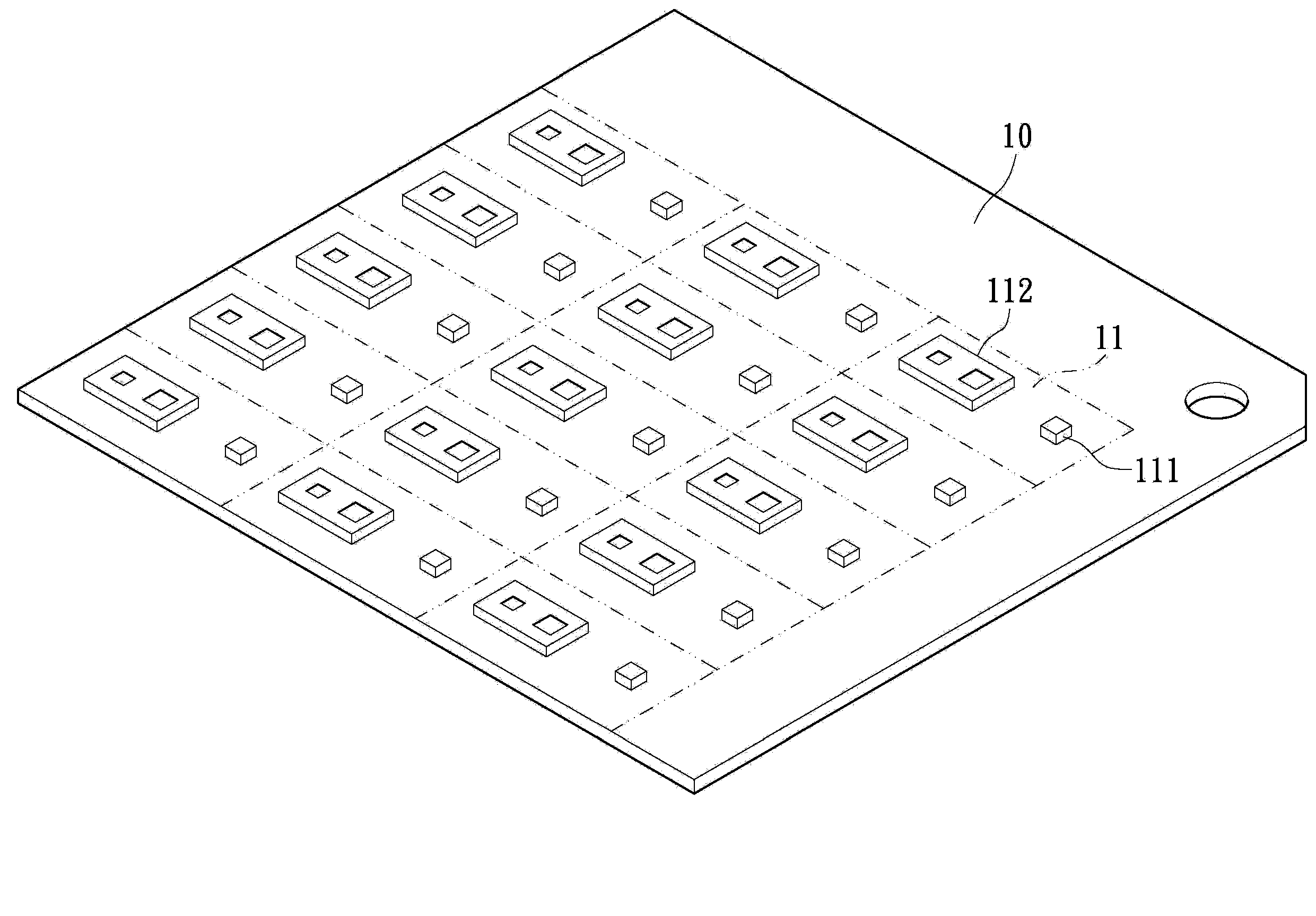

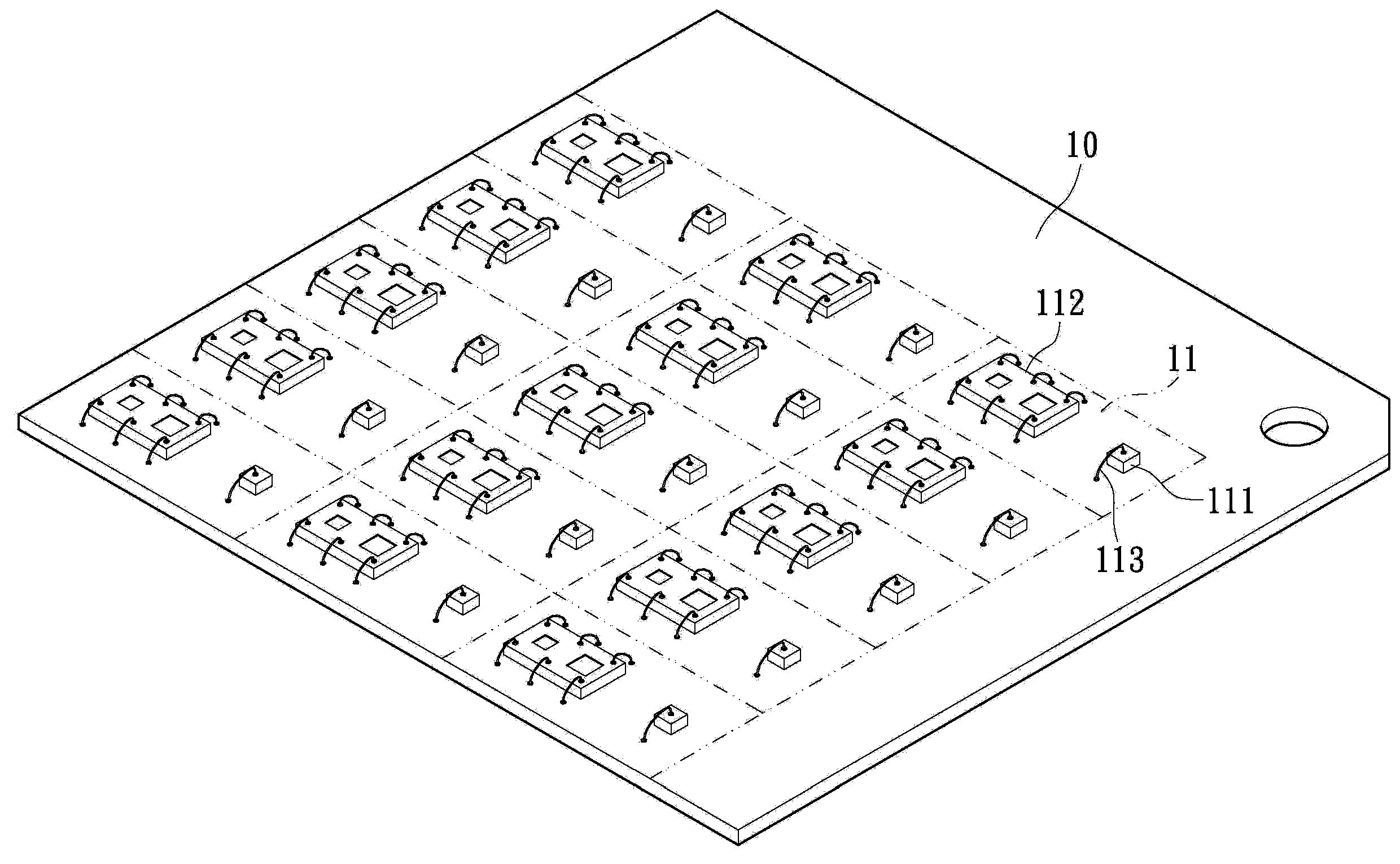

[0039] Please refer to figure 1 As shown, figure 1 The substrate 10, which is the method of manufacturing the sensor unit 1 of the present invention, has a three-dimensional schematic diagram of a signal transmitter 111 and a signal detector 112. First, a substrate 10 is provided, and a plurality of signal transmitters 111 and a plurality of signal detectors 112 are provided, and the plurality of signal transmitters 111 and a plurality of signal detectors 112 are attached to the substrate 10, each of which is The combination of the sensor 111 and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com