High-safety lithium ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of high-safety lithium-ion batteries, can solve problems such as explosion, battery system damage, and combustion, and achieve the effect of improving safety performance and preventing combustion or even explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

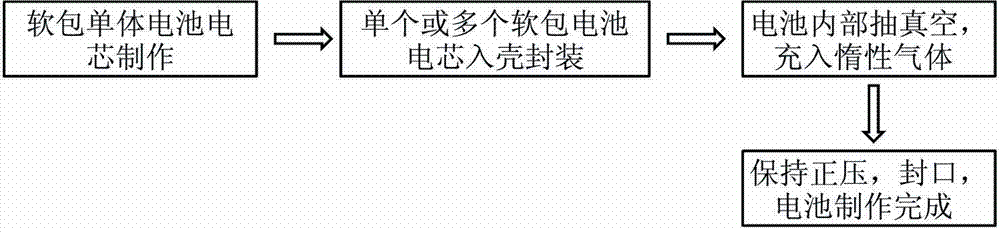

[0027] Utilize the method for the present invention to make battery capacity and be 60Ah high safety lithium-ion battery, can implement according to the following steps:

[0028] (1) Make three soft-packed lithium-ion battery cells with a battery capacity of 20Ah by winding or stacking;

[0029] (2) Put three soft-packed lithium-ion battery cells with a battery capacity of 20Ah into the steel case and seal it;

[0030] (3) Use a pump to pump out the air inside the battery, put it in a vacuum state, fill it with 99.999% high-purity nitrogen, keep the pressure in the battery case at 0.15MPa, seal it, and the battery is completed.

Embodiment 2

[0032] Utilize the method for the present invention to make battery capacity and be 50Ah high safety lithium-ion battery, can implement according to the following steps:

[0033] (1) Two soft-packaged lithium-ion battery cells with a battery capacity of 20Ah and one soft-packaged lithium-ion battery cell with a battery capacity of 10Ah are produced by winding or lamination;

[0034] (2) Put 3 soft-packed lithium-ion battery cells into the plastic case and seal it;

[0035] (3) Use a pump to pump out the air inside the battery, put it in a vacuum state, fill it with 99.999% high-purity argon, keep the pressure in the battery case at 0.01MPa, seal it, and the battery is completed.

Embodiment 3

[0037] Utilizing the method of the present invention to make battery capacity is that 10Ah high-safety lithium-ion battery can be implemented according to the following steps:

[0038] (1) Manufacture a soft-packed lithium-ion battery cell with a battery capacity of 10Ah by winding or stacking;

[0039] (2) Put a single 10Ah soft-packed lithium-ion battery cell into the aluminum case and seal it;

[0040] (3) Use a pump to pump out the air inside the battery, put it in a vacuum state, fill it with 99.8% carbon dioxide gas, keep the pressure in the battery case at 0.1MPa, seal it, and the battery is completed.

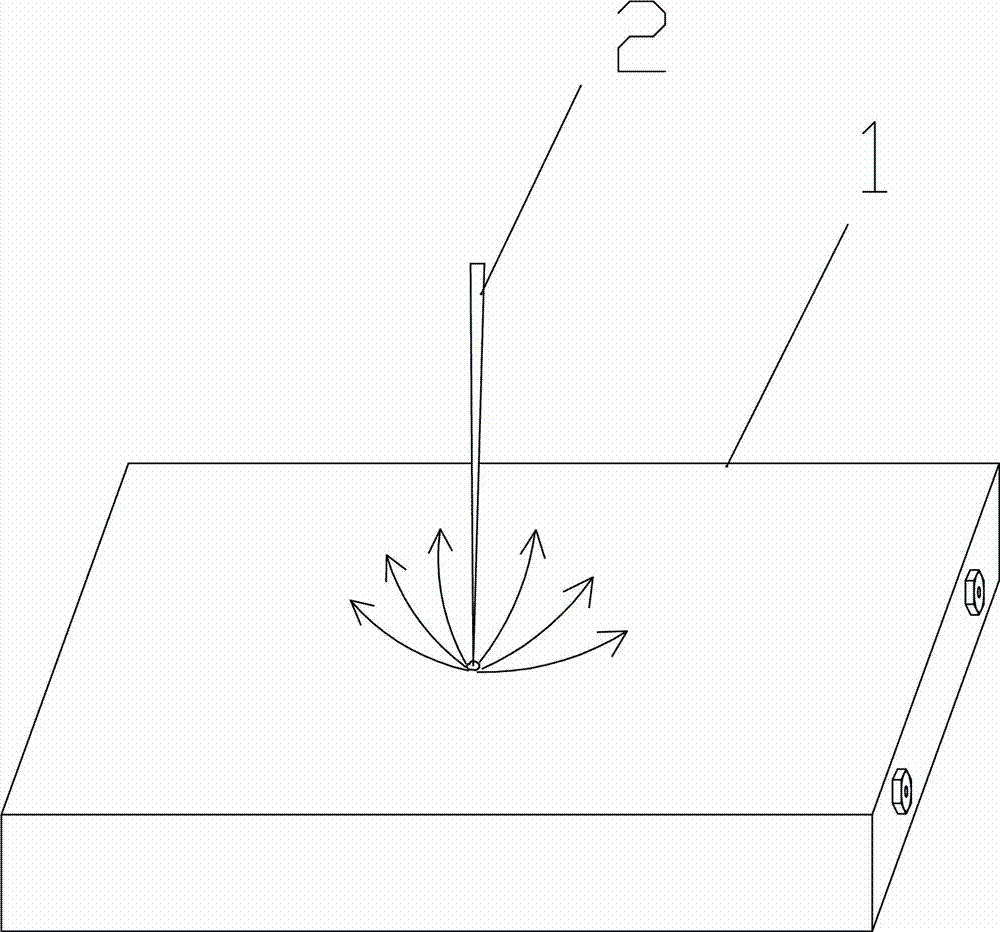

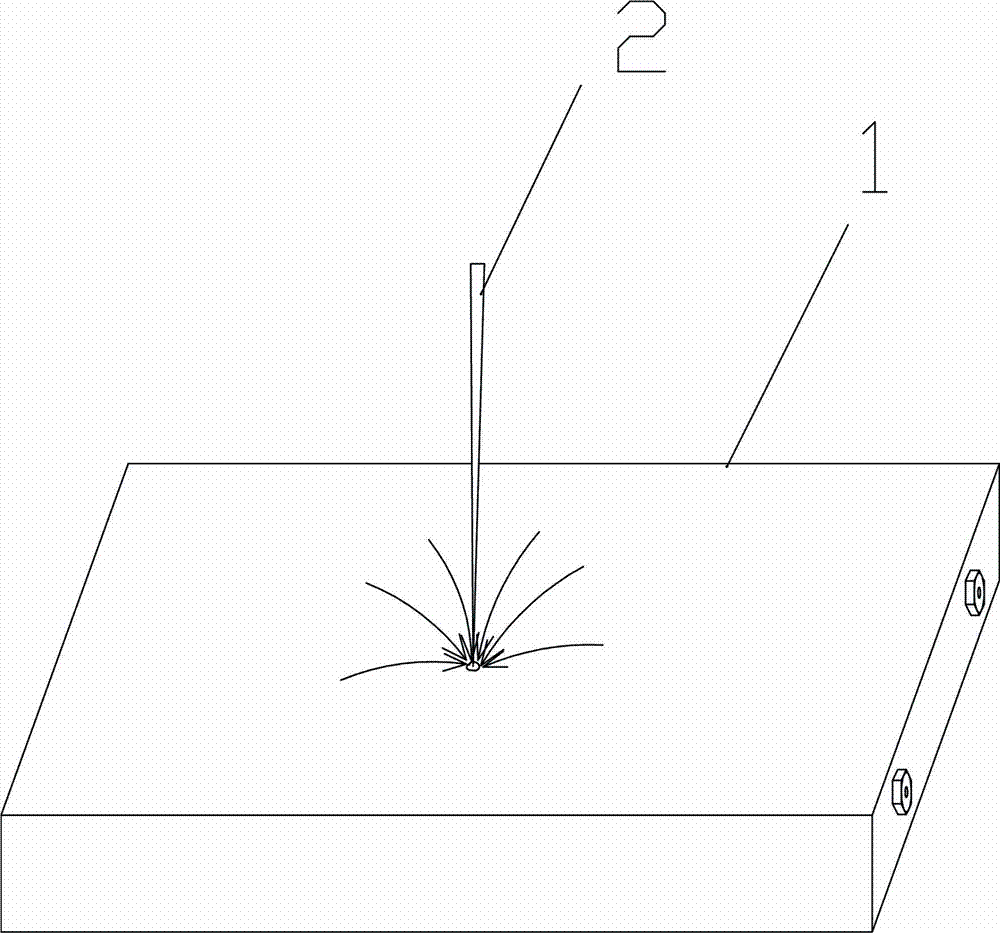

[0041] In order to check the safety of the lithium ion battery produced by the method of the present invention, acupuncture experiments were performed on the lithium ion battery. figure 2 It is the effect diagram after acupuncture of the lithium ion battery of the present invention, image 3 It is the rendering of traditional lithium-ion battery after acupuncture. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com