Illuminated glass panel for a vehicle, and manufacture thereof

A technology for glass windows and vehicles, which is applied to windshields, optical components, vehicle parts, etc., can solve the problems of huge costs and the inability to upgrade glass window units, and achieve the effect of eliminating dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

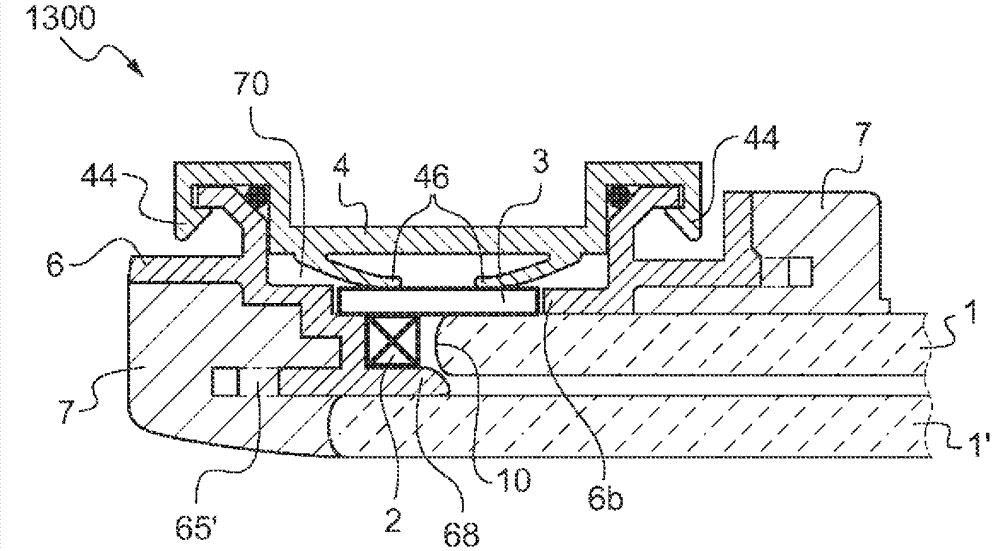

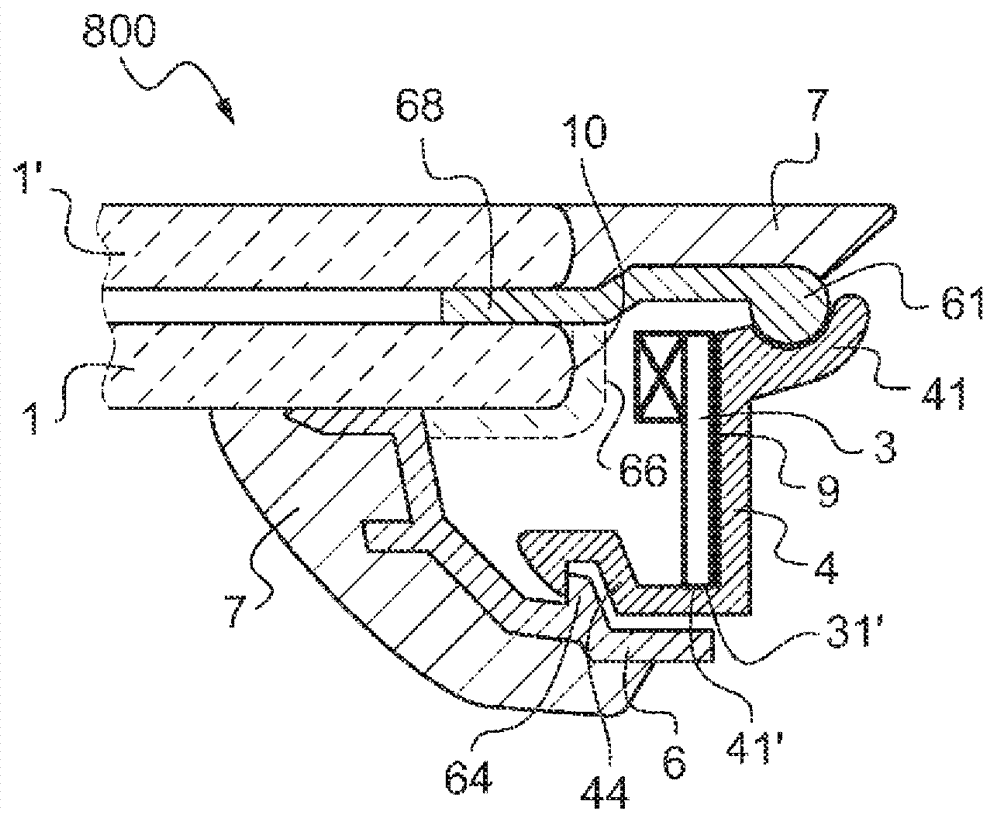

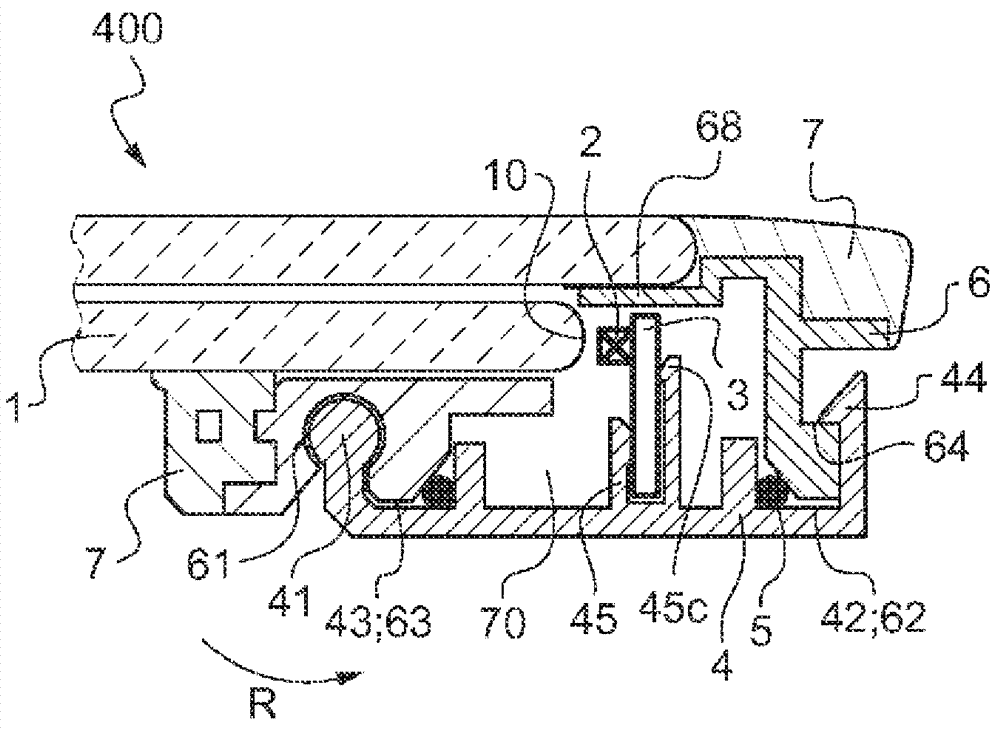

[0328] Fig. 1 shows a partial schematic cross-sectional view of a light-emitting glass window unit 100 for a vehicle in a first embodiment of the present invention.

[0329] The glass window unit 100 includes a laminated glass window unit, which includes:

[0330] -For example, a rectangular first transparent plate 1 with a first main surface 11 and a second main surface 12, and an edge surface 10, such as a silica-soda lime glass plate, having a thickness equal to 2.1 mm,

[0331] -The second plate 1', possibly used for solar shielding function, dyed (for example VENUS VG10 glass from Saint-Gobain) and / or covered with a solar shielding coating with a thickness equal to 2.1mm, and has a main surface 13 and a free assembly surface 14 .

[0332] The second glass plate 1'is laminated by a laminated spacer 8 having a thickness of 0.76 mm such as PVB.

[0333] The profiled member 3 as a support for the light emitting diode 2 extends along the periphery, for example, the longitudinal directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com