Control system for air source heat pump drying production line

An air source heat pump and control system technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as large power consumption, and achieve the effects of energy saving, convenient operation, and intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

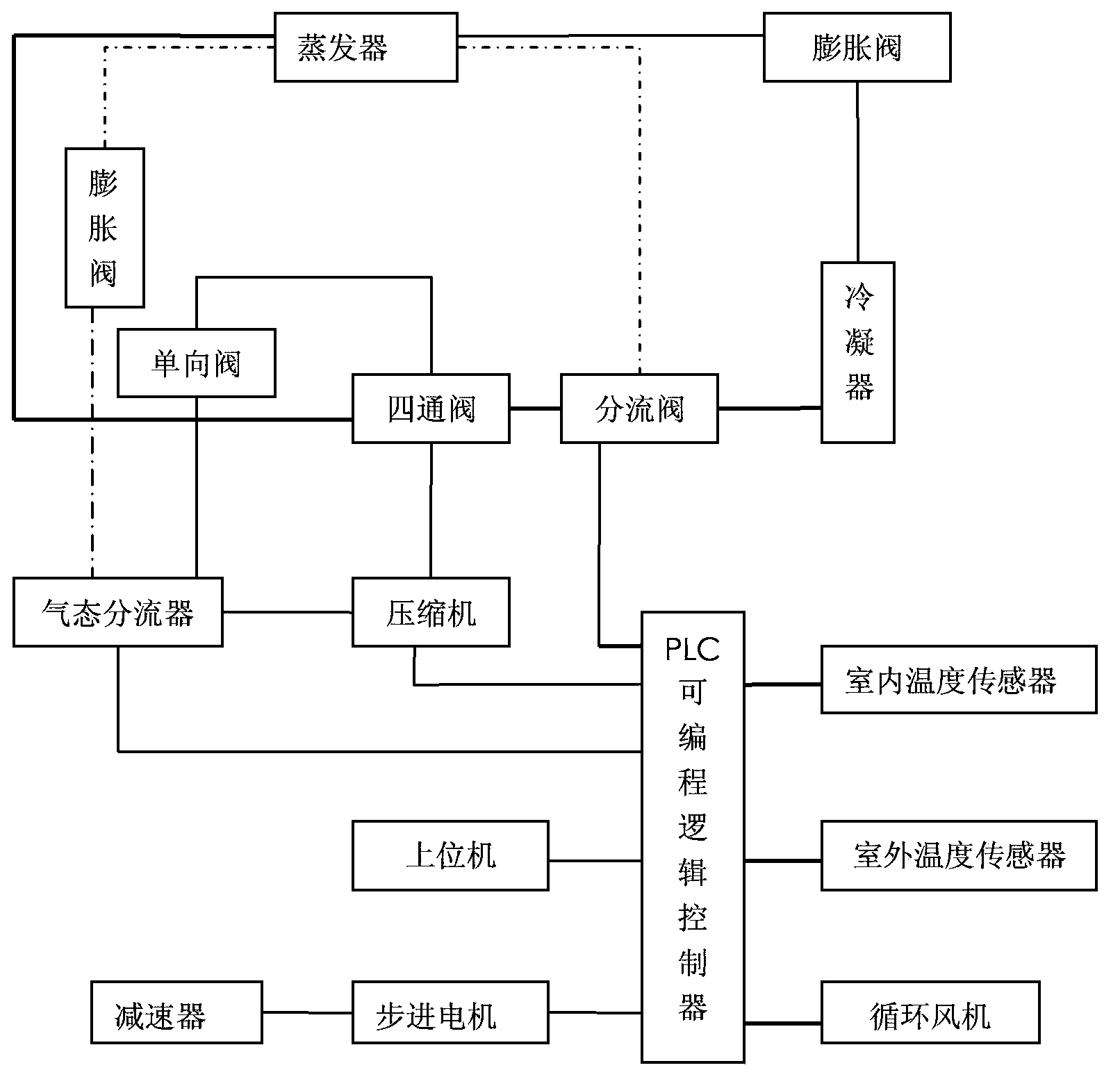

[0012] Referring to the accompanying drawings, the technical solution adopted by the present invention is a control system for an air source heat pump drying production line, which is mainly composed of an air source heat pump unit, a PLC programmable logic controller, a temperature sensor, a host computer, a circulating fan and a stepping motor Composition; the air source heat pump unit includes an evaporator, an expansion valve, a gas-liquid splitter, a compressor, a splitter valve, and a condenser. The PLC programmable logic controller is connected with the indoor temperature sensor, the outdoor temperature sensor, and the The circulating fan, the stepping motor are connected with the upper computer; the stepping motor is connected with the reducer to drive the conveyor belt on the drying production line to run.

[0013] Further, the air source heat pump unit mainly provides heat source for the drying box, the condenser in the air source heat pump unit is installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com