Reactor capable of pretreating high-solid-content lignocelluloses raw materials

A technology of lignocellulose and high solid content, applied in the direction of chemical/physical/physicochemical fixed reactors, etc., can solve the problem of insufficient contact between high-temperature steam and materials or chemical reagents, increase the cost of pretreatment process and biological processing, and disadvantageous Problems such as high solid content saccharification and product fermentation, to achieve the effect of improving pretreatment efficiency, improving pretreatment effect, and strengthening pretreatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

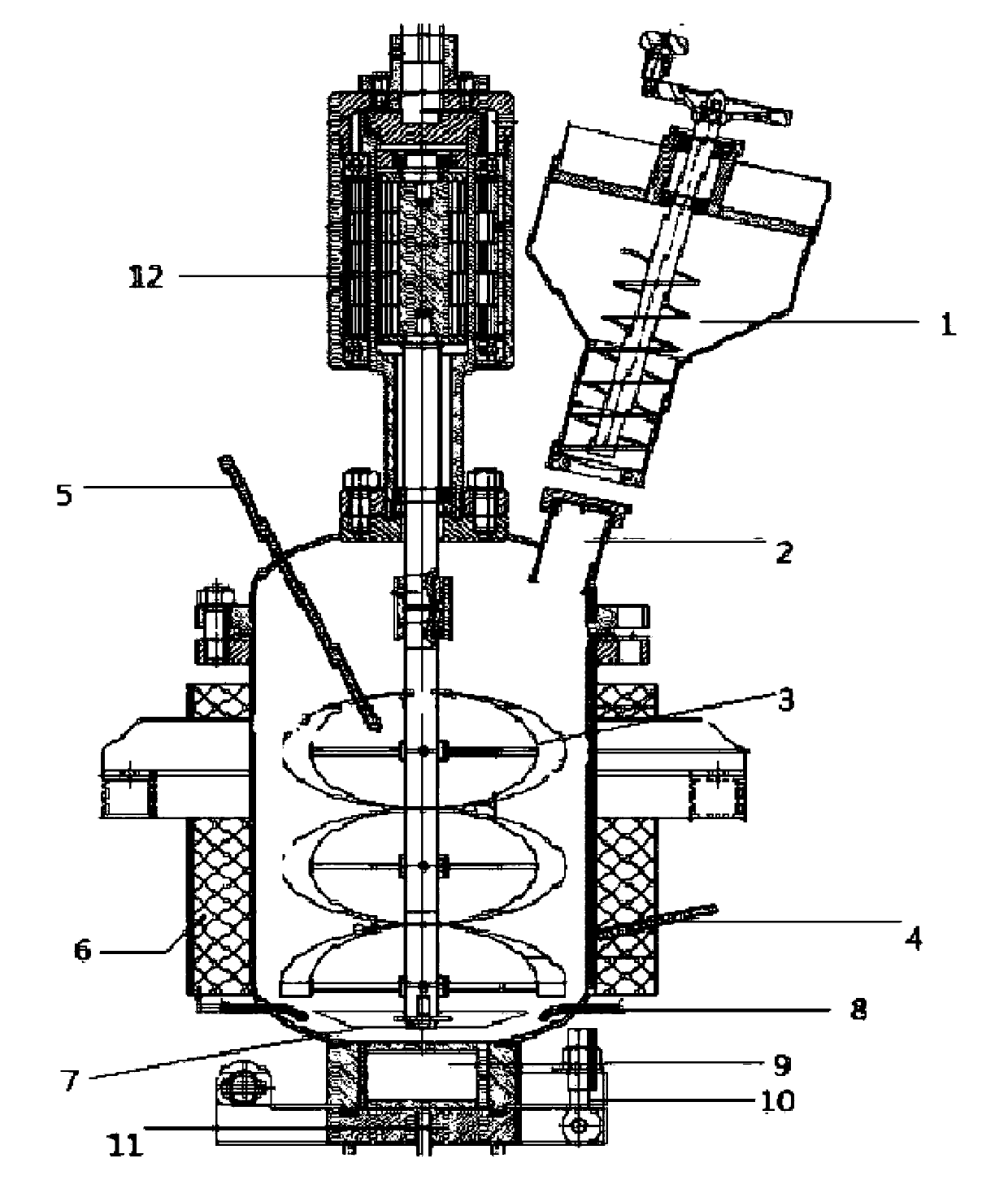

[0022] Please see attached figure 1 , a kind of reactor that can carry out the pretreatment of lignocellulosic raw material with high solid content, the kettle body is equipped with a mechanical stirring device, the mechanical stirring device includes a combined stirring paddle, it is characterized in that, the combined stirring paddle is a screw belt paddle 3 and a scraping bottom Paddle 7; the propeller paddle is fixed on the stirring shaft through the support rod, and hovers around the stirring shaft from top to bottom to form a frame; the bottom scraping paddle is fixed at the bottom end of the stirring shaft and is close to the bottom of the kettle body; the bottom scraping paddle Paddle or anchor paddle.

[0023] The mechanical stirring device, that is, the transmission device 12, is directly driven by the motor for stirring or the motor-magnetic steel transmission magnetic stirring; the mechanical stirring device is fixed on the top of the kettle body by bolts;

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com