Method for preparing xylitol by fermenting xylose secondary mother liquor

A technology of xylitol and xylose hydrolyzate, which is applied in the field of xylitol production by secondary fermentation of xylose mother liquor, can solve the problems of complex fermentation operation steps, low conversion rate of xylitol, high production cost, etc., and avoid conversion The efficiency is low, it is convenient for subsequent purification, and the effect of saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

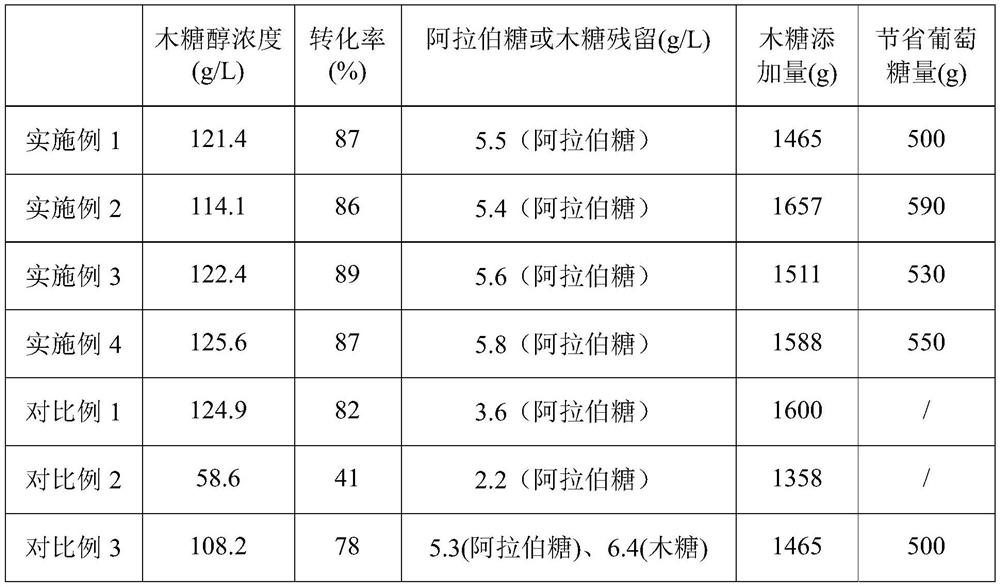

Embodiment 1

[0045] A kind of first embodiment of the method that utilizes xylose secondary mother liquor fermentation to prepare xylitol of the present invention, comprises the steps:

[0046] Step 11, preparation of xylose concentrate: add 0.4% Ca(OH) to the xylose hydrolyzate before separation 2 , stirring at 50 rpm for 15 min, controlling the pH to 3.2, then adding activated carbon with a mass ratio of 0.4% for decolorization, controlling the temperature at 60° C., and stirring at 60 rpm for 90 min. After the decolorization is completed, the filtered xylose liquid is concentrated in a low-temperature vacuum, and the vacuum pump pressure is set at -0.095MPa, the water bath temperature is 60°C, the rotation speed is 60rpm, and the flow rate of the condensed water is about 200mL / min until the refraction of the concentrated solution is about 65%. Xylose concentrate suitable for fermentation.

[0047] Step 12, strain activation and preparation of seed solution: select recombinant Escherich...

Embodiment 2

[0054] A kind of second embodiment of the method that utilizes xylose secondary mother liquor fermentation to prepare xylitol of the present invention comprises the steps:

[0055] Step 21, preparation of xylose concentrate: add 0.5% Ca(OH) to the xylose hydrolyzate before separation 2 , stirred at 30 rpm for 30 min, controlled pH 3.0, then added 0.5% activated carbon by mass for decolorization, controlled temperature at 70°C, and stirred at 30 rpm for 60 min. After the decolorization is completed, the filtered xylose liquid is concentrated in a low-temperature vacuum, and the vacuum pump pressure is set at -0.085MPa, the water bath temperature is 70°C, the rotation speed is 50rpm, and the condensed water flow rate is about 150mL / min until the refraction of the concentrated solution is about 60%. Xylose concentrate suitable for fermentation.

[0056] Step 22, strain activation and preparation of seed solution: select the recombinant Escherichia coli strain IS5-M, activate the...

Embodiment 3

[0063] A kind of third embodiment of the method that utilizes xylose secondary mother liquor fermentation to prepare xylitol of the present invention comprises the steps:

[0064] Step 31, preparation of xylose concentrate: add 0.4% Ca(OH) to the xylose hydrolyzate before crossing 2 , stirring at 50 rpm for 15 min, controlling the pH to 3.5, then adding activated carbon with a mass ratio of 0.3% for decolorization, controlling the temperature at 60° C., and stirring at 60 rpm for 90 min. After the decolorization is completed, the filtered xylose liquid is concentrated in a low-temperature vacuum, and the vacuum pump pressure is set at -0.095MPa, the water bath temperature is 60°C, the rotation speed is 60rpm, and the flow rate of the condensed water is about 200mL / min until the refraction of the concentrated solution is about 65%. Xylose concentrate suitable for fermentation.

[0065] Step 32, strain activation and seed solution preparation: select recombinant Escherichia col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com