Automatic coating production line for steel spare parts

An automatic coating and production line technology, applied in the device, coating, spraying device, etc. for coating liquid on the surface, can solve the problems of low degree of automation and harm, improve production quality, reduce injury, and improve labor productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

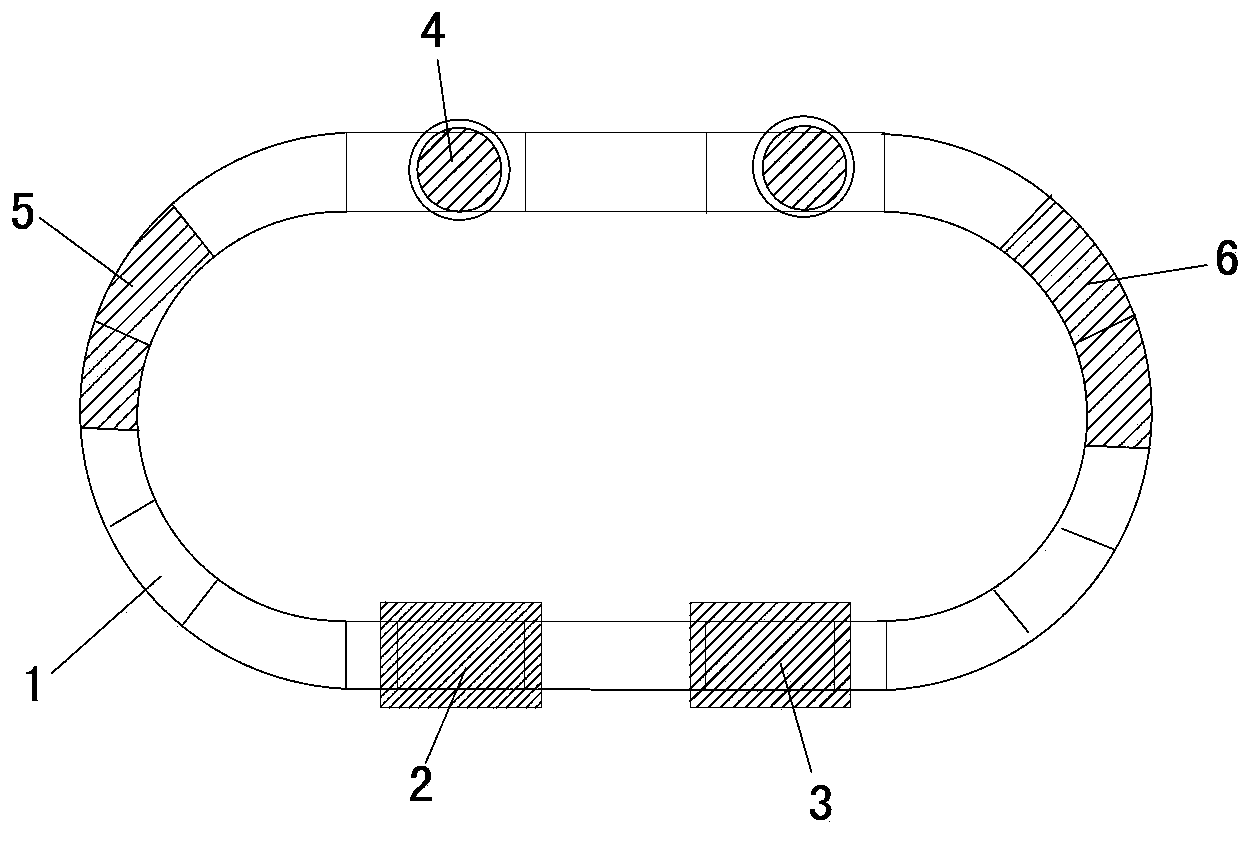

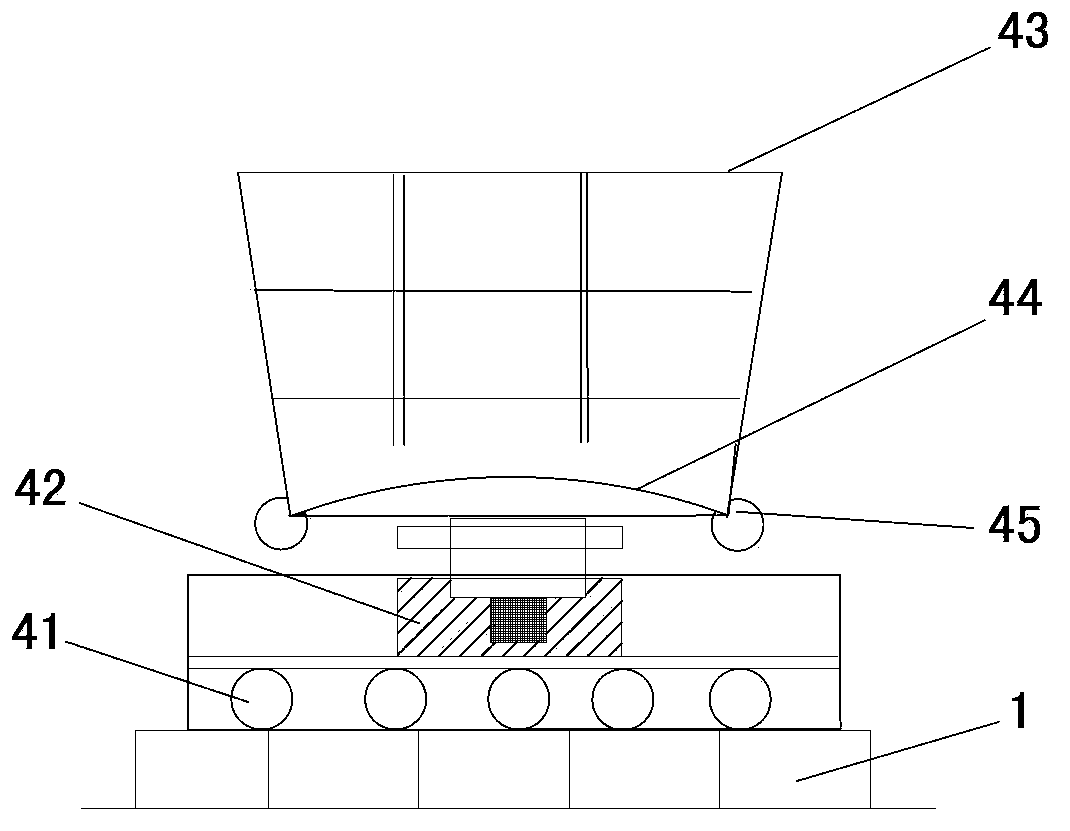

[0015] see figure 1 , with reference to Figure 4 , Figure 5 , the automatic coating production line for steel structure parts of the present invention is arranged in the painting workshop, including a circular track 1, and an automatic closed painting box 2 and a drying box 3 are fixed overhead on the circular track 1. At least one rotary working platform frame 4 that can move along the track is erected on the circular track, and a loading area 5 and an unloading area 6 are respectively arranged on the path of the circular track. The rotating work platform frame 4 moves along the circular track 1 to the loading area 5 to load steel structural parts, then moves to the automatic closed painting box 2 for coating, then moves to the drying box 3 for drying, and then moves to the unloading area 6 for unloading , to complete the automatic painting of steel parts. One or more rotary working platform frames are used in a cyclic operation.

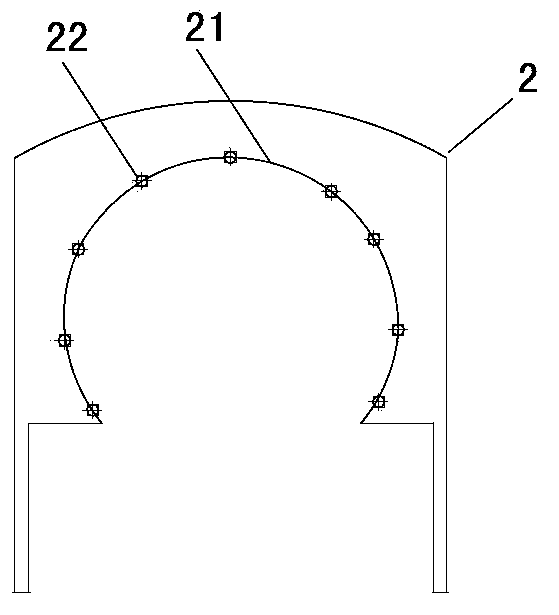

[0016] Cooperate see figure 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com