Combined mold

A composite mold and mold body technology, applied in the field of composite molds, can solve the problems that are not conducive to controlling the dimensional accuracy and surface quality of the blank, affect the dimensional accuracy and surface quality of the blank, increase the grinding amount of the blank product, etc., and meet the requirements of ensuring smoothness. , Improve surface quality, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

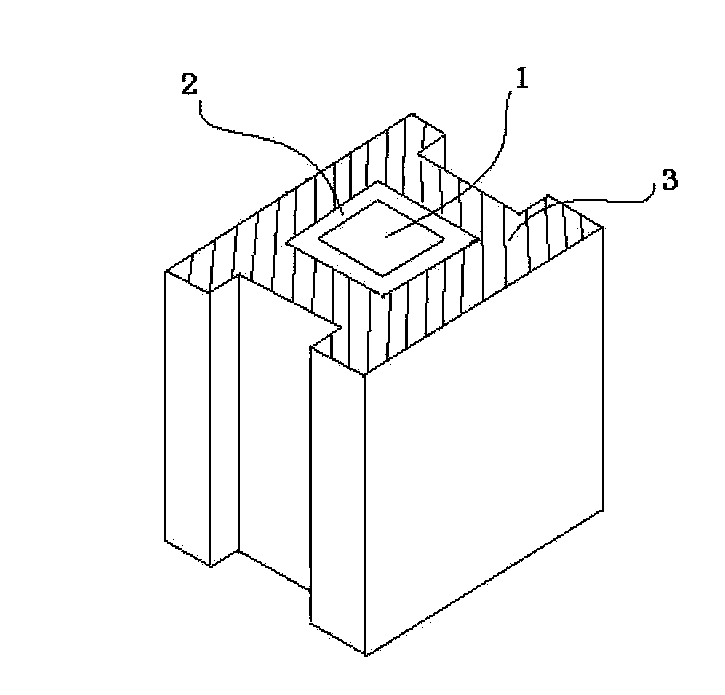

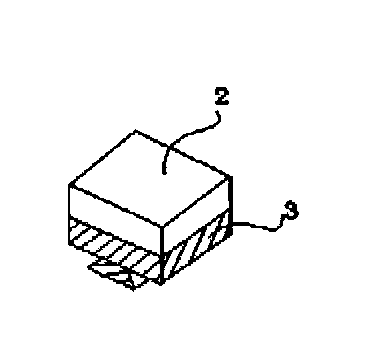

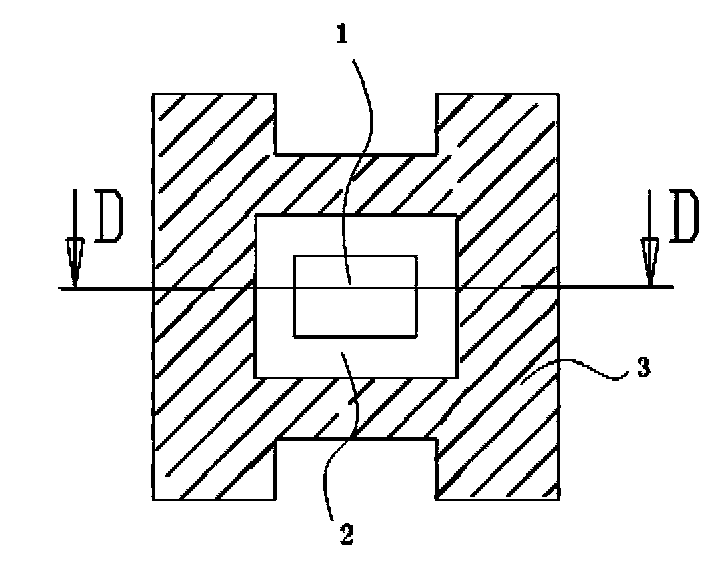

[0035] Figure 2A , 2B , 2C is a structural schematic diagram of a mold for pressing a block-shaped product, as shown in the figure, 1 is a mold cavity, 2 is a graphite material layer, and 3 is a magnetically conductive material layer. The mold body is composed of an outer magnetic material layer and an inner 5mm thick graphite material layer, and the upper and lower indenters are also composed of magnetic material and graphite material, and the thickness of the graphite material layer in contact with the pressed powder is also 5mm. The friction coefficient of the graphite material layer ranges from 0.04 to 0.1, and the thermal expansion coefficient ranges from (0.5 to 3)*10 -6 K -1 , the Mohs intensity value ranges from 1 to 3, and the smoothness value ranges from >0.4. Pour the NdFeB micropowder into the cavity of the mold, then carry out the mold clamping orientation, then the upper and lower block-shaped product pressure heads enter the mold cavity for bidirectional pre...

Embodiment 2

[0041] Figure 3A , 3B , 3C is a structural schematic diagram of a mold for pressing a cylindrical product, as shown in the figure, 1 is a mold cavity, 2 is a graphite material layer, and 3 is a magnetically conductive material layer. The mold body is composed of an outer magnetic material layer and an inner 10mm thick graphite material layer, and the upper and lower indenters are also composed of magnetic material and graphite material, and the thickness of the graphite material layer in contact with the pressed powder is also 10mm. The friction coefficient of the graphite material layer ranges from 0.04 to 0.1, and the thermal expansion coefficient ranges from (0.5 to 3)*10 -6 K -1, the Mohs intensity value ranges from 1 to 3, and the smoothness value ranges from >0.4. Pour the NdFeB micropowder into the cavity of the mold, then carry out the mold clamping orientation, then the upper and lower block-shaped product pressure heads enter the mold cavity for bidirectional pre...

Embodiment 3

[0047] Figure 4A , 4B , 4C is a structural schematic diagram of a mold for pressing trapezoidal products, as shown in the figure, 1 is a mold cavity, 2 is a graphite material layer, and 3 is a magnetically conductive material layer. The mold body is composed of an outer magnetic material layer and an inner 30mm thick graphite material layer, and the upper and lower indenters are also composed of magnetic material and graphite material, and the thickness of the graphite material layer in contact with the pressed powder is also 30mm. The friction coefficient of the graphite material layer ranges from 0.04 to 0.1, and the thermal expansion coefficient ranges from (0.5 to 3)*10 -6 K -1 , the Mohs intensity value ranges from 1 to 3, and the smoothness value ranges from >0.4. Pour the NdFeB micropowder into the cavity of the mold, then carry out the mold clamping orientation, then the upper and lower block-shaped product pressure heads enter the mold cavity for bidirectional pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com