Laser cutting machine capable of generating period cutting depth

A laser cutting machine, cutting depth technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high equipment cost, reduce the degree of side wall ablation, and low cost, and achieve ablation The effect of reduced area, low degree of ablation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

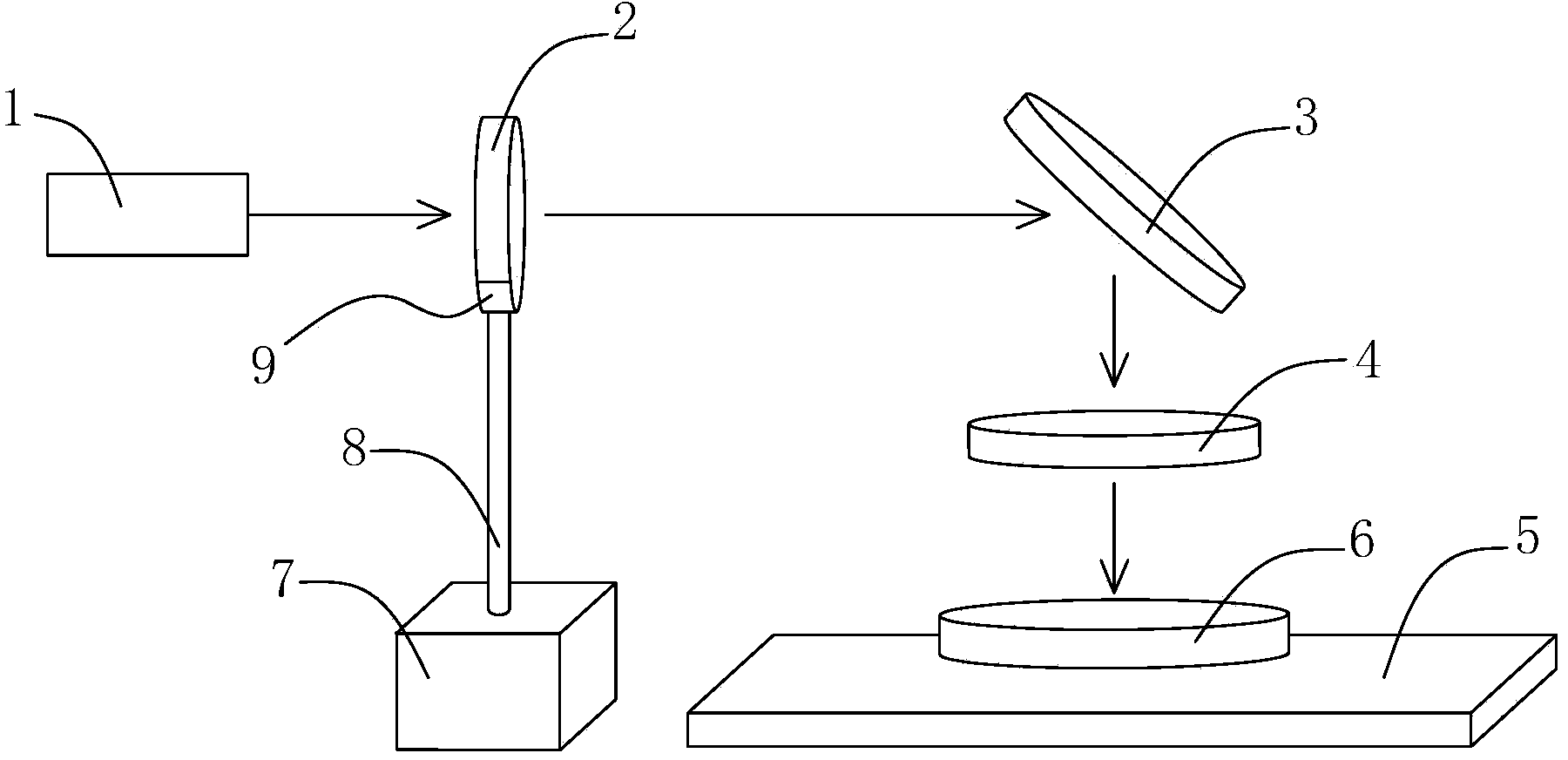

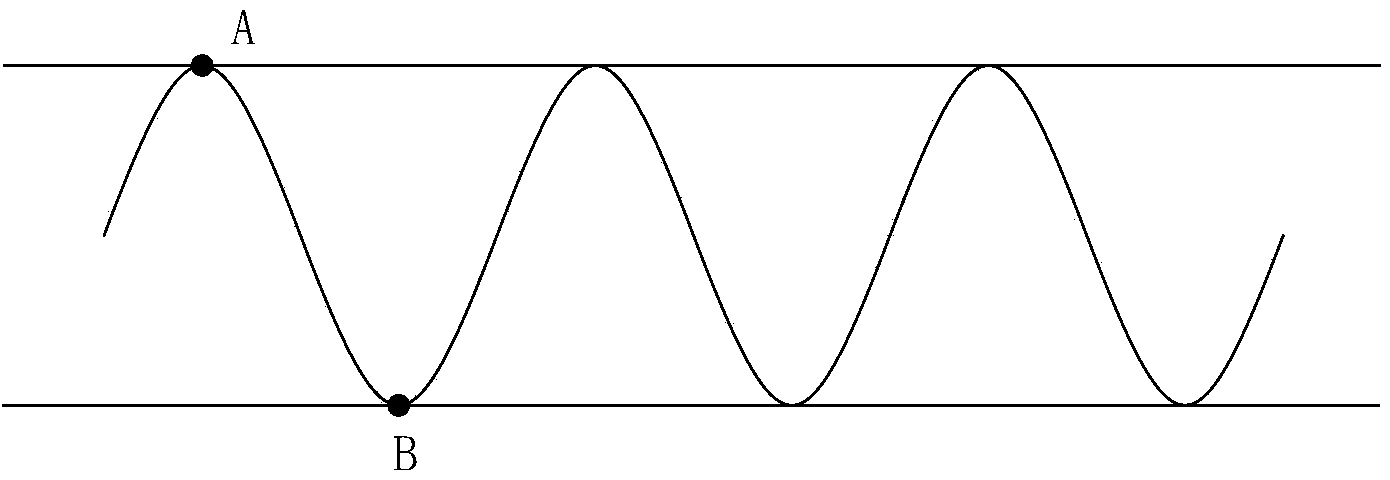

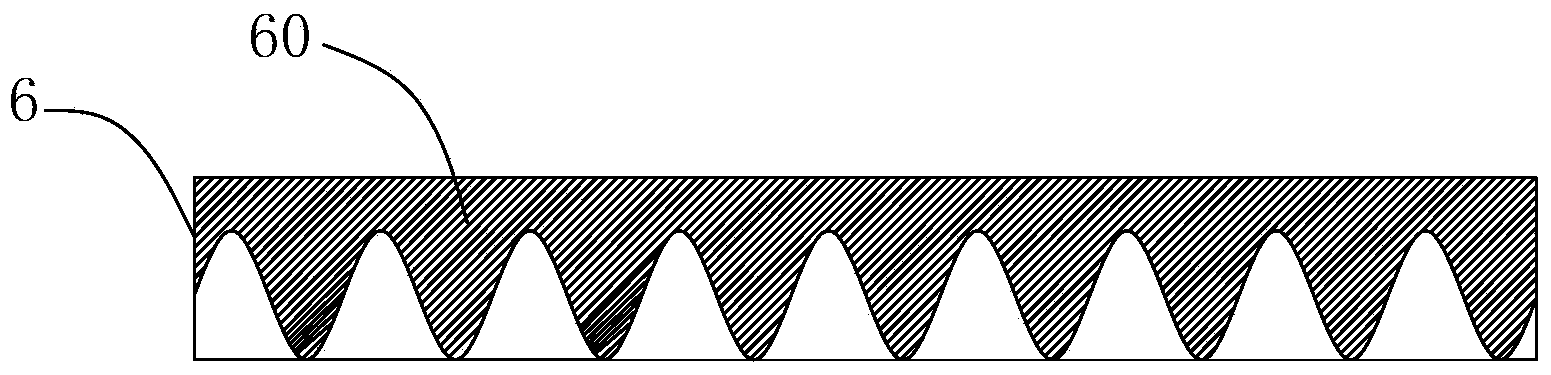

[0019] The invention discloses a laser cutting machine capable of producing periodic cutting depth, which combines Figure 1 to Figure 3 As shown, it includes a laser head 1 and a rotating mechanism 7. Along the laser transmission direction of the laser head 1, a 1 / 2 wave plate 2, a mirror 3, a focusing mirror 4 and a moving stage 5 are arranged in sequence, and the LED chip 6 is placed on the On the mobile stage 5, the 1 / 2 wave plate 2 is arranged at the power output end of the rotating mechanism 7. As a preferred mode, the power output end of the rotating mechanism 7 is provided with a driving rod 8, and the driving rod 8 The end of the hollow seat 9 is provided, the 1 / 2 wave plate 2 is fixed on the hollow seat 9, and the rotation mechanism 7 drives the 1 / 2 wave plate 2 along the diameter of the 1 / 2 wave plate 2 In practical applications, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com