High-precision screw and screw nut screwing device

A high-precision, nut technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that screws and nuts do not form the scale of the production line, affecting the production efficiency of enterprises, and achieve the effect of consistent speed and high-quality positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

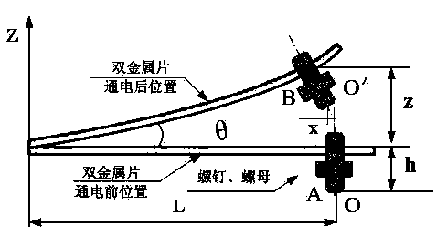

[0022] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0023] Due to the small installation space of the overall device in actual use, the whole device should be compact and flexible, and can also realize the entire functional process. Therefore, the device adopts a micro servo motor to drive the inner sleeve and the outer sleeve to rotate, and the inner sleeve It consists of two parts, one is the part connected with the motor, and the other is the part for tightening the screws. The two parts are connected by a flexible steel wire rope, which is at the advanced and leading level in China.

[0024] In order to realize the adjustment of the screw and nut without additional force, a synchronous control strategy for the mutual cooperation of the two motors is designed, which can well eliminate the difference error and installation error of the motor itself, and ensure the high precision requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com