Built-in tool magazine structure

A technology of tool magazine and inner cavity, which is applied in the field of built-in tool magazine structure, can solve the problems of column deformation, unfavorable machine tool accuracy, and long auxiliary tool change time, and achieve the effects of reducing distortion, improving processing efficiency, and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

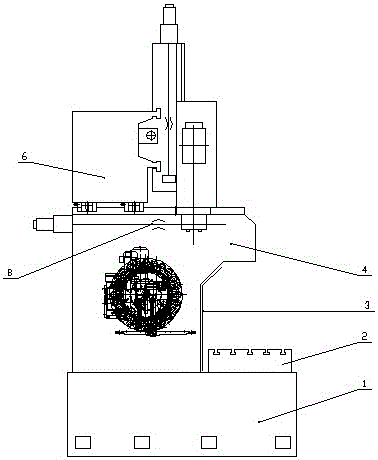

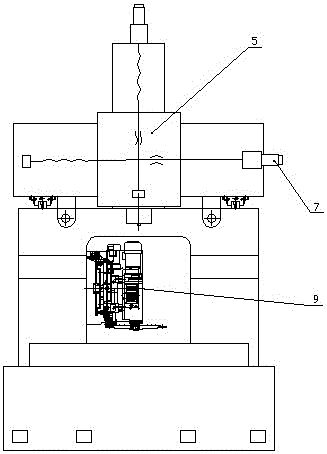

[0013] A built-in tool magazine structure, such as figure 1 As shown, it includes: a workbench 2 and a base 1, the workbench 2 and the base 1 are an integrated structure, the base 1 is equipped with a column 4, the column 4 adopts a wide body design, and the interior is an arch bridge structure, The bridge-shaped inner cavity of the column 4 is installed with a disc tool magazine 9, and the disc tool magazine 9 is fixed on the column 4 with a tool magazine bracket, and the X-axis servo motor 7 and the main shaft are installed on the column 4. Skateboard 5, Y-direction crossbeam 6 and double lead screw 8, described X-axis servo motor 7 can drive main shaft slide plate 5 to the position of disc tool magazine 9, Y-direction crossbeam 6 moves and adopts double lead screw 8 driving structure.

[0014] In this embodiment: an automatic door 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com