Combined Rotary Drive Unit

A rotary drive, combined technology, applied in metal processing mechanical parts, metal processing, measuring/indicating equipment, etc., can solve the problem of large installation space and volume, achieve less installation space, improve equipment processing accuracy, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

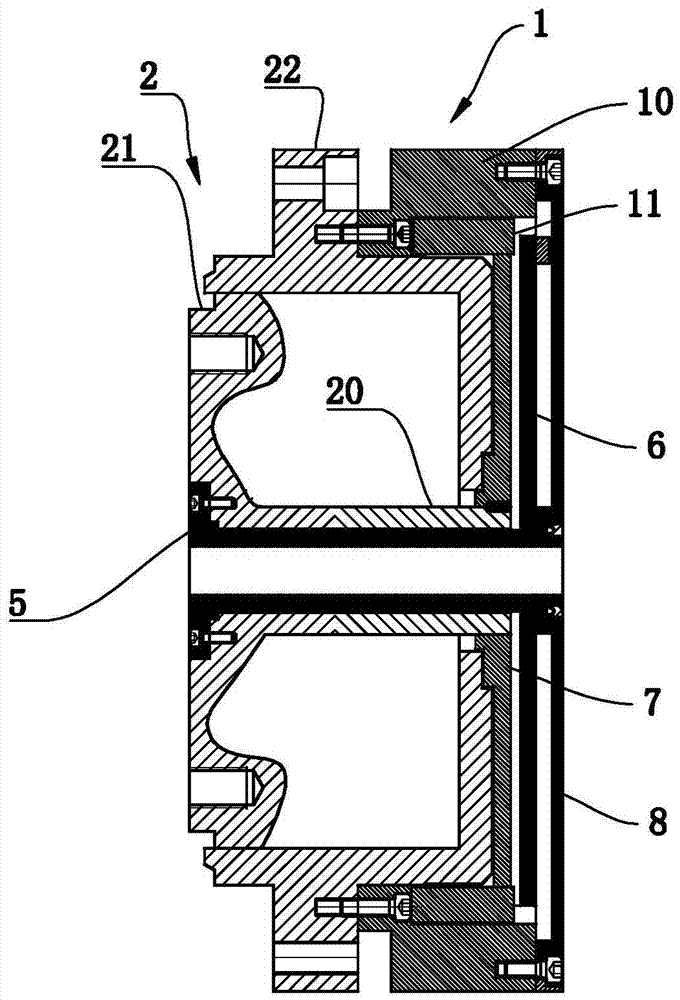

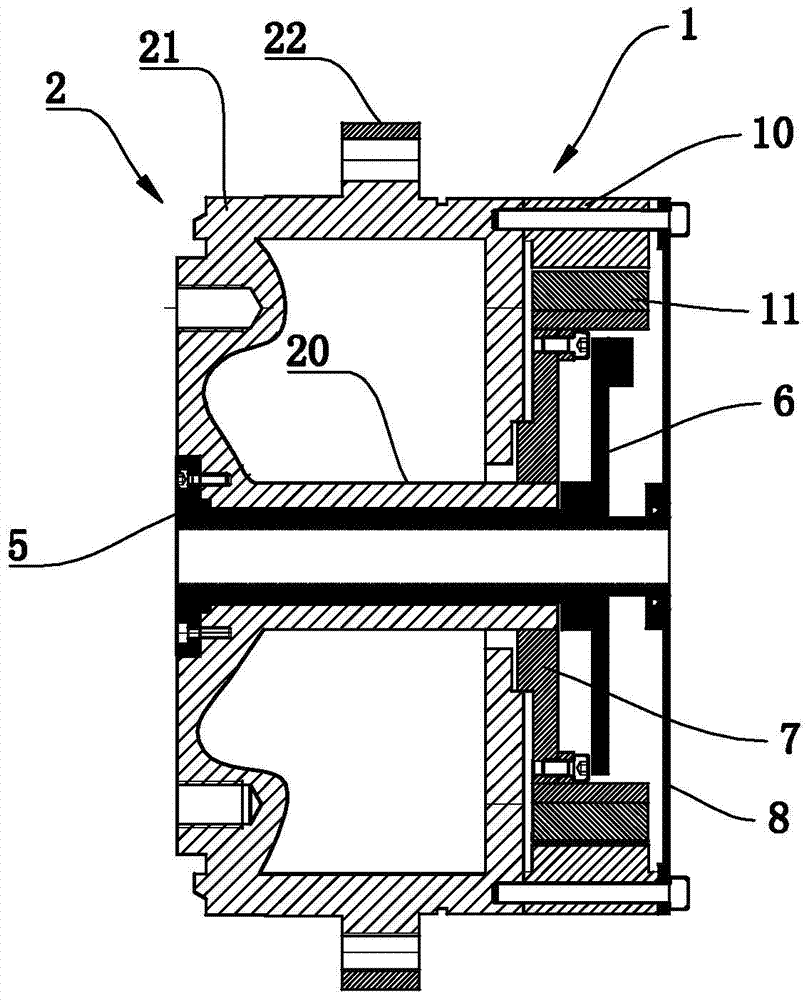

[0020] like figure 1 and figure 2 Commonly shown in , a combined rotary drive unit includes a reducer driven by a direct drive servo motor, the stator of the direct drive servo motor is fixedly connected to the housing of the reducer, and the rotor of the direct drive servo motor passes through a flange 7 Connect with the input terminal of the reducer.

[0021] The output end of the reducer is connected to the detection device used to eliminate the transmission gap. The detection device includes a connecting sleeve 5 that runs through the center hole of the reducer. One end of the connecting sleeve 5 is fixedly connected to the output end of the reducer, and the other end is connected to the encoder. 6 or grating ruler connection, the encoder or grating ruler is connected to the direct drive servo motor through the electronic control unit.

[0022] The reducer is a harmonic reducer 2, the direct drive servo motor is a frameless direct drive servo motor 1, the stator 10 of t...

Embodiment 2

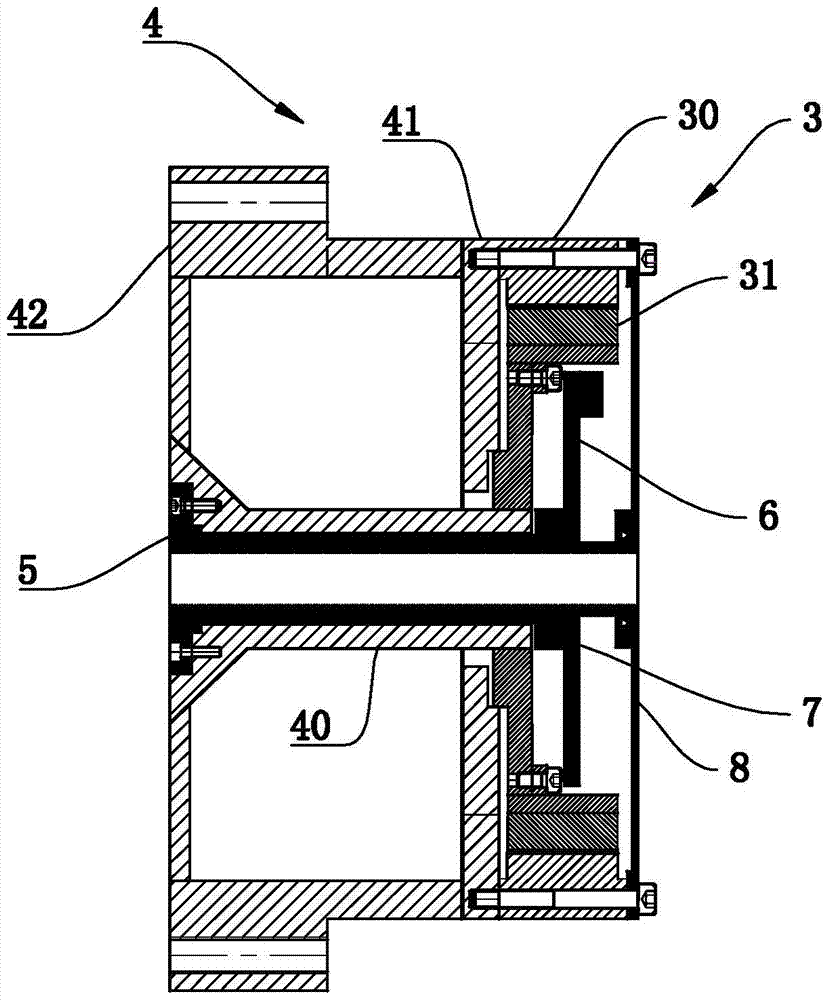

[0028] like image 3 As shown in , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the reducer is a harmonic reducer 4, the direct drive servo motor is a frameless direct drive servo motor 3, and the frameless direct drive servo motor 3 The stator 30 of the harmonic reducer 4 is fixedly connected with the steel wheel 41 of the harmonic reducer 4, the rotor 31 of the frameless direct drive servo motor 4 is connected with the wave generator 40 of the harmonic reducer 4 through the flange 7, and the sleeve 5 is connected One end is connected with the output end of the flexible wheel 42 of the harmonic reducer 4 through a fastener, and the other end is connected with the encoder 6 or the grating scale, and the encoder 6 or the grating scale is connected with the frameless direct drive servo motor 3 through the electronic control unit .

[0029] When in use, the drive unit composed of the frameless direct drive servo motor 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com