Outward turning device for bamboo tube, and outward turning and splitting method of bamboo tube

A technology of bamboo tubes and metal tubes, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of destroying the bamboo structure, thick fibers, and uniformity that cannot meet the production of textile fibers, etc., and achieve the effect of controllable length and neat bamboo fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: select the fresh Cizhu with a bamboo age of 8 months;

[0036] Step 2: remove the bamboo tips and elbows from the whole bamboo material that has a small difference in diameter between the head and the tail, and cut it into 350 cm bamboo tubes 200 with an electric saw, and remove the bamboo partitions by perforating;

[0037] Step 3: Put the bamboo tube 200 into a clear water pool for steaming, the heating temperature is 95°C, and the heating time is 15 minutes. The outer wall of the bamboo tube 200 turns yellow-gray, and then it is taken out immediately;

[0038] Step 4: Flip out the fibers:

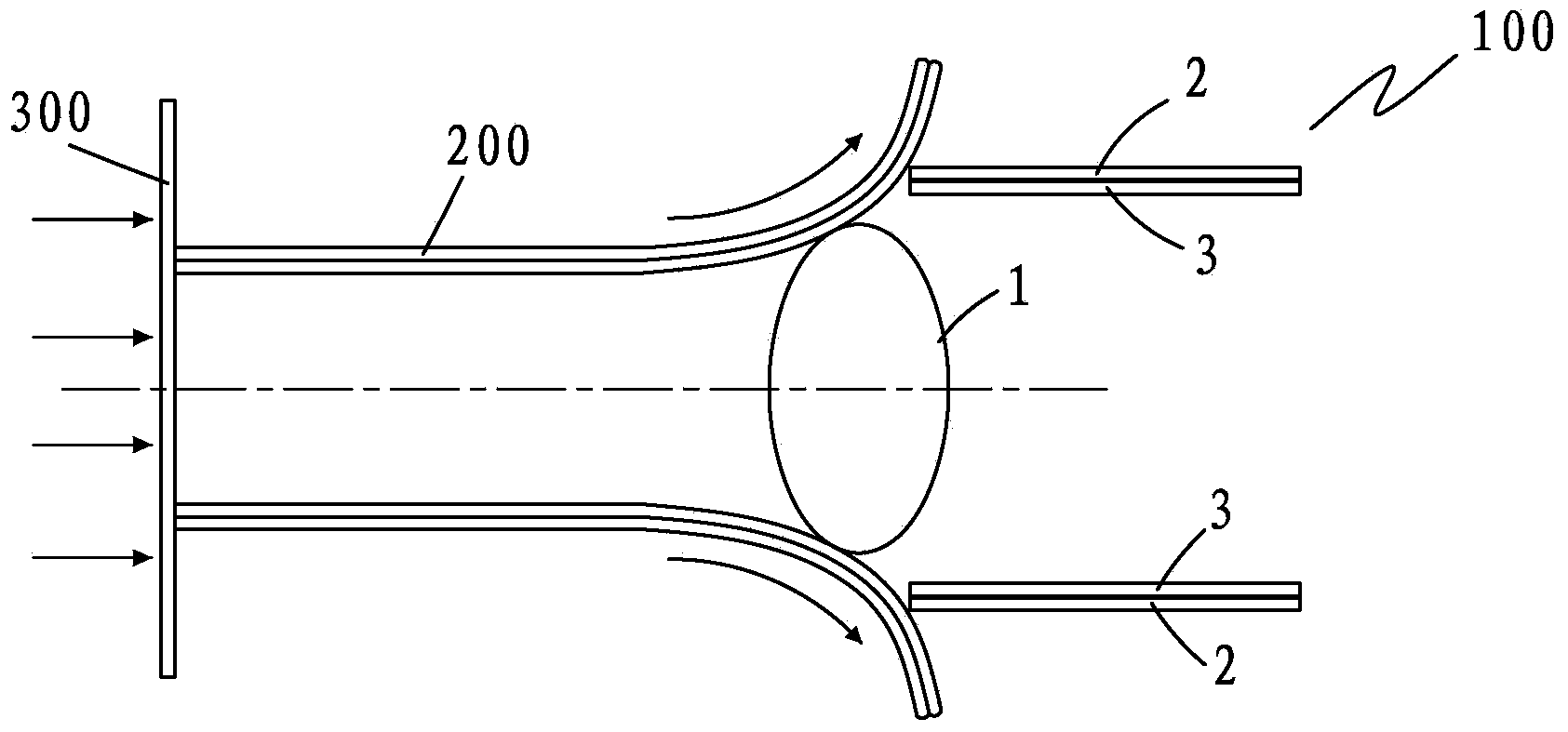

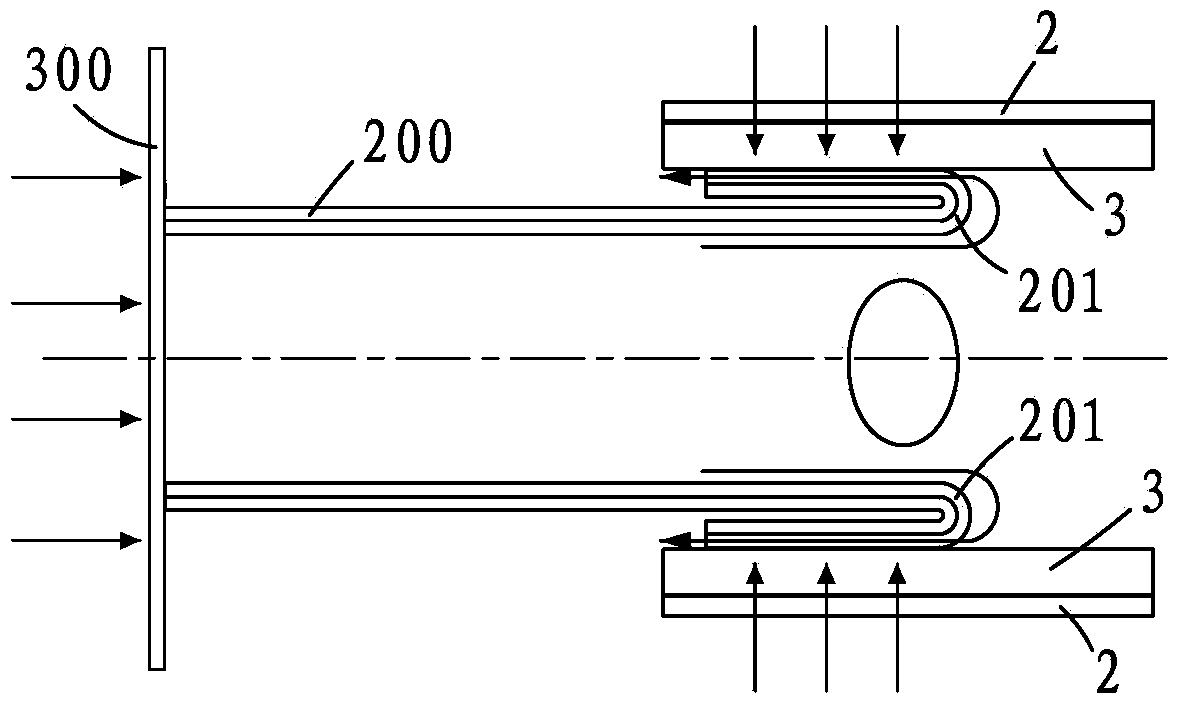

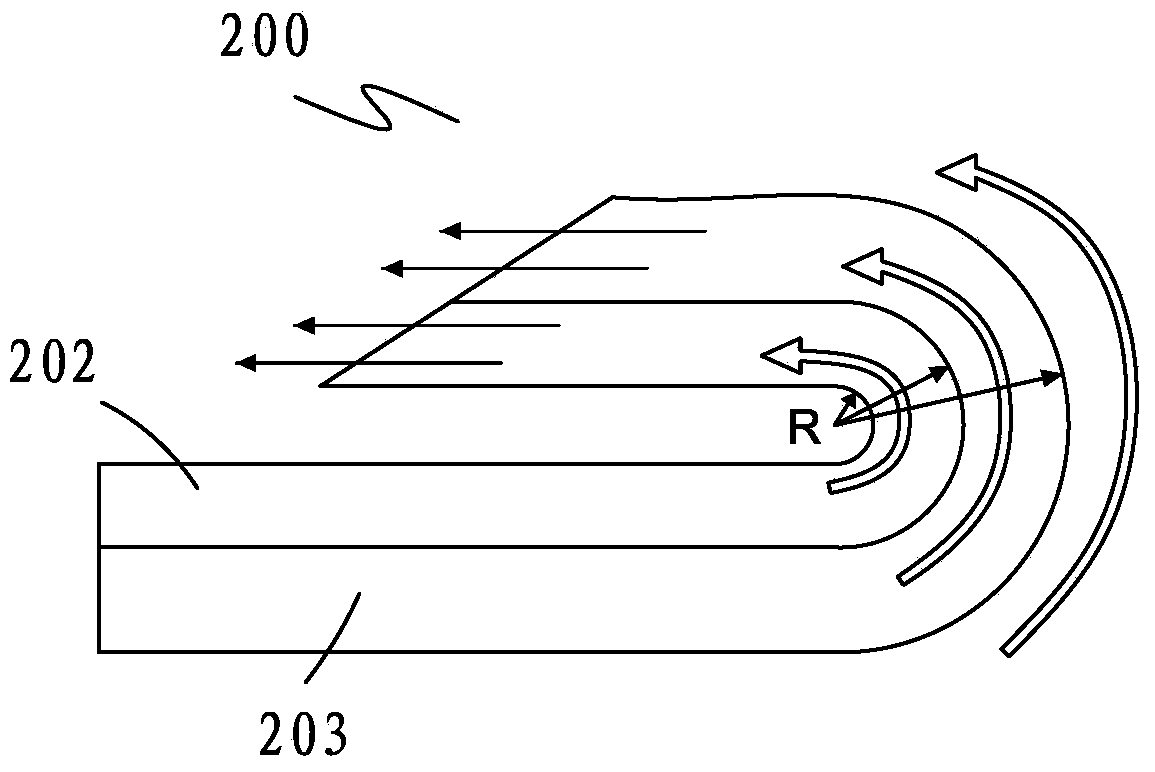

[0039] A. Take the softened bamboo tube 200, fix one end of the bamboo tube 200, extend the expansion air bag 1 into the other end inner wall of the bamboo tube 200 by 5 cm, inflate the expansion air bag 1, and the expansion air bag 1 utilizes air pressure to push the bamboo tube 200 side Crack and disperse, and then use the metal tube 2 to push into the opened inner wall...

Embodiment 2

[0043] This part differs from Example 1 in that:

[0044] Step 1: select bamboo age to be 2 years moso bamboo;

[0045] Step 2: Use a chainsaw to cut into a 50cm bamboo tube;

[0046] Step 3: Heating temperature 100°C, heating time 45min;

[0047] Step 4: Flip out the fibers:

[0048] A. Stretch the expansion air bag 1 into the other end inner wall of the bamboo tube 200 by 15cm

Embodiment 3

[0050] This part differs from Example 1 in that:

[0051] Step 1: select bamboo age to be 1.5 years moso bamboo;

[0052] Step 2: Use a chainsaw to cut into a 200cm bamboo tube;

[0053] Step 3: The heating temperature is 100°C, and the heating time is 25 minutes.

[0054] Step 4: Flip out the fibers:

[0055] A. Stretch the expansion air bag 1 into the other end inner wall of the bamboo tube 200 by 10cm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com