RTM (resin transfer moulding) mould with resin intercepting outlet

An export and mold technology, applied in the field of RTM molds, can solve the problems of air bubbles remaining in the product, product defects, resin waste, etc., and achieve the effect of reducing resin loss, reducing resin loss, and reducing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

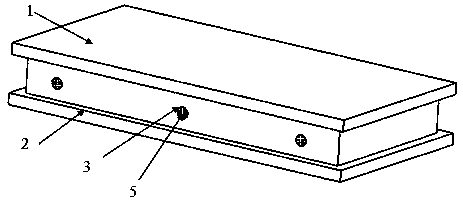

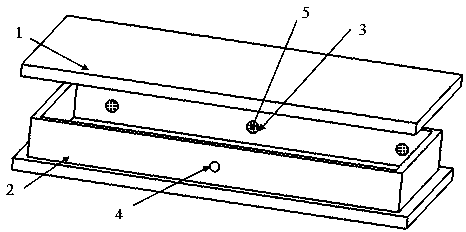

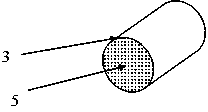

[0018] Such as figure 1 and figure 2 As shown, the present embodiment provides a kind of RTM mold that is provided with resin shut-off outlet, comprises upper mold 1 and lower mold 2, and described lower mold 2 is provided with glue injection port 4 and several glue outlets 3, and described glue injection port 4 and the glue outlet 3 are respectively arranged on different side walls of the lower mold 2, and the glue outlet 3 is provided with a metal sieve 5. The metal sieve 5 is a detachable metal sieve 5, which can be taken out and replaced mechanically after the resin is immersed in the metal sieve 5 and cured. The metal sieve 5 is cylindrical, such as image 3 As shown, the inside of the metal sieve 5 is a sponge-like structure, and the mesh diameter of the metal sieve 5 is 0.1-0.3 mm, preferably 0.2 mm, which can effectively reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com