Production process and system equipment of heavy oil calcined cement

A cement production process and heavy oil technology, which is applied in the field of heavy oil calcined cement production process and system equipment, can solve the problems of affecting the safe operation of the preheater system, high content of harmful components of sulfur and alkali, and skinning of the preheater system, so as to avoid High temperature of the kiln head, fuel saving and stable flame effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The patent will be further described below in conjunction with specific embodiments.

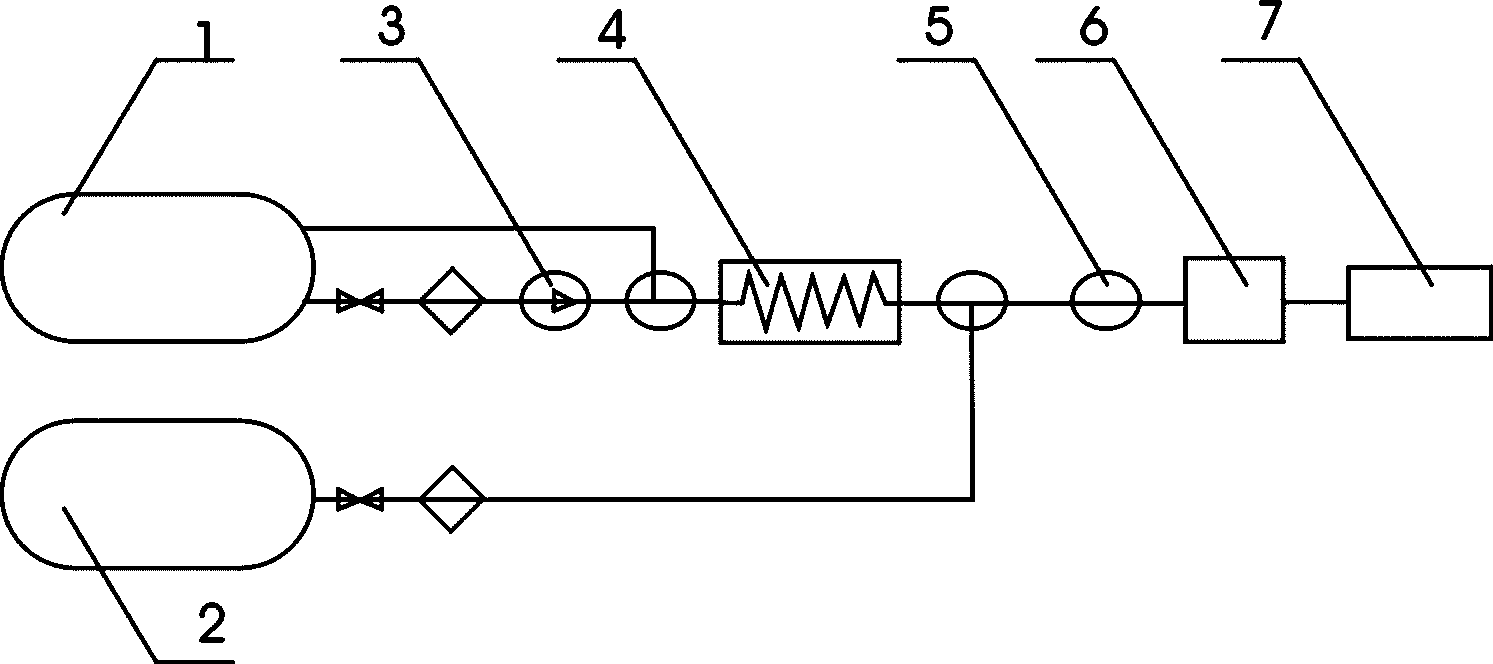

[0027] The heavy oil calcined cement production process includes the following steps:

[0028] a. The heavy oil at the ambient temperature of the heavy oil tank is sent from the heavy oil tank to the heat exchanger through the oil filter and the heavy oil supply pump;

[0029] b. The heavy oil is first heated to about 130 degrees. The medium for heating the heavy oil in the heat exchanger is high-temperature heat exchange oil. The high-temperature resistant oil is heated to 260 degrees in the boiler and then sent to the heat exchanger. High temperature oil has been accompanied by heavy oil;

[0030] c. After the heavy oil is pressurized, the pressure is adjusted to 3.5~4.0MPa through the automatic control circuit. After obtaining the temperature and pressure, the heavy oil enters the burner in two ways. The two ways are swirl oil and axial flow oil respectively. Circumferentially di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com