Joint protection plate for underground continuous wall, construction machine and construction method

An underground continuous wall and construction equipment technology, applied in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of long time for bagging, high physical labor intensity of workers, slow bagging speed, etc., to reduce construction costs, Good economic benefits and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

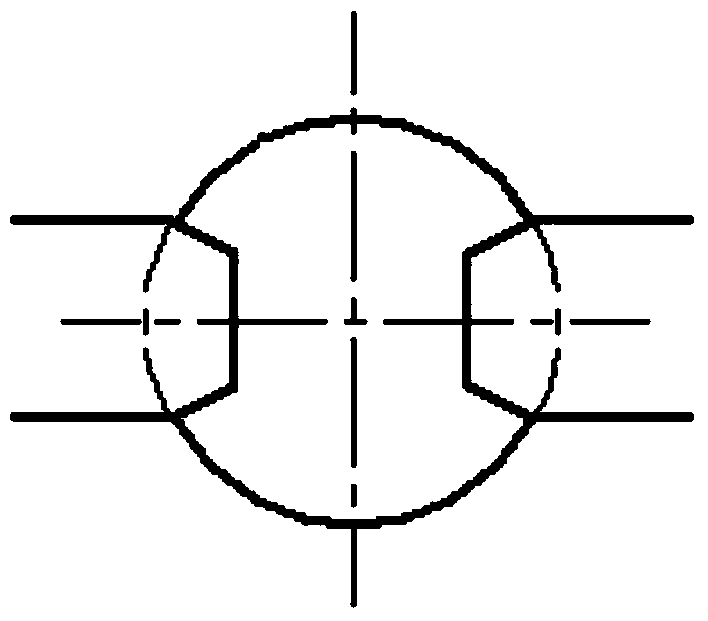

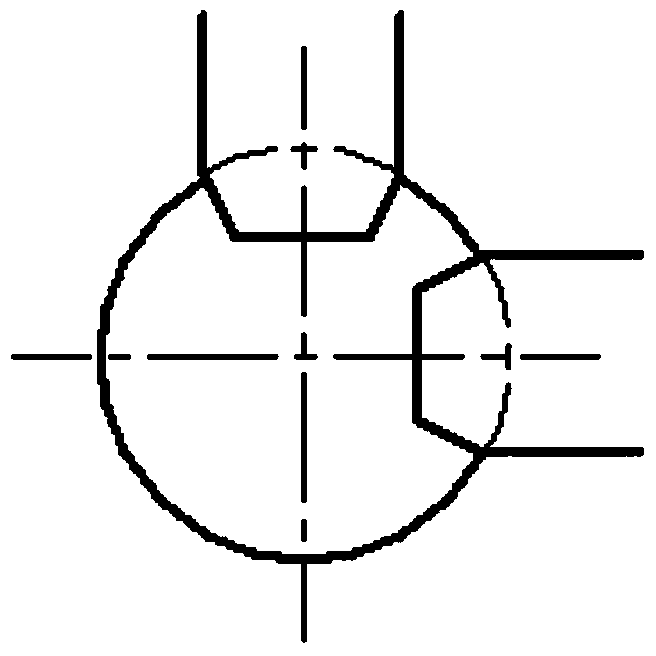

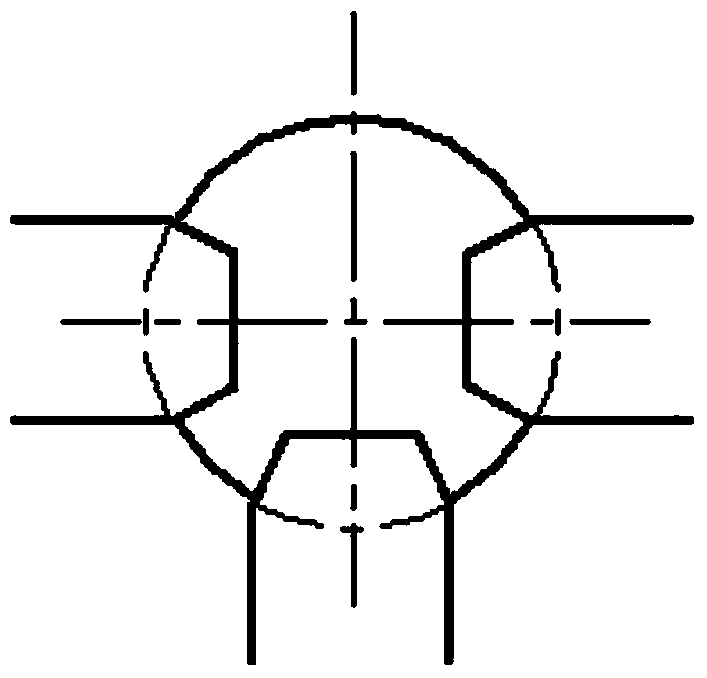

[0037] see Figure 5 to Figure 20 , the underground diaphragm wall joint protection plate of the present invention, its key technology is that the protection plate is an arc-shaped plate 4, and the arc-shaped plate 4 includes a lifting plate, a standard plate and a bottom plate, one end of the lifting plate and the bottom plate, and one end of the standard plate The two ends are welded with a bolted connecting plate 6, and the upper and lower ends of the standard plate are respectively connected with the lifting plate and the base plate through the bolted connecting plate 6.

[0038] The inner wall of the arc-shaped plate 4 is welded with support bars 3 inside the plate. The distance between the support bars 3 in the plate is 50-80 cm. strip.

[0039] The inner wall of the arc-shaped plate 4 is located on the outside of the bolted plate 6 and is provided with a reinforcement block 5 , one end of which is fixed on the inner wall of the arc-shaped plate 4 , and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com