Split type wheel excavator chassis

An excavator and split-type technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of wheeled excavators unable to walk, increase the purchase investment of the owner, affect the operation efficiency, etc., to improve the product adaptability to the market. capacity, obvious social and economic benefits, and the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

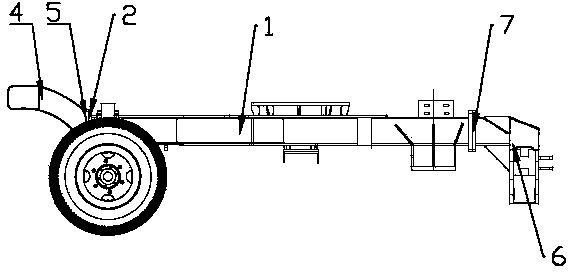

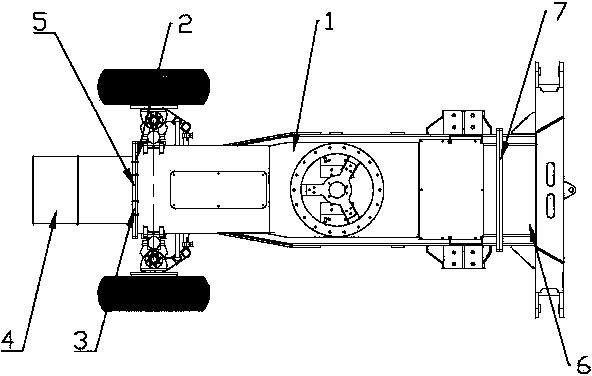

[0027] Such as figure 1 , figure 2 As shown, the chassis of a split type wheeled excavator of the present invention includes a chassis main frame 1, and the front end and the rear end of the chassis main frame 1 are respectively provided with connecting flanges 2 connecting the chassis main frame 1 as a whole. The periphery of the flange 2 is provided with a plurality of screw holes 3 for connecting functional accessories.

[0028] The functional accessory connected to the front end of the chassis main frame 1 is a shovel head support frame 4, and the shovel head support frame can support the shovel head to avoid the shovel head from swinging left and right. The shovel head support frame 4 is provided with a support frame bottom plate 5, and the periphery of the support frame bottom plate 5 is provided with screw holes corresponding to the screw holes on the connecting flange 2 at the front end of the chassis main frame 1, and the two are connected by bolts. stand up.

[0...

Embodiment 2

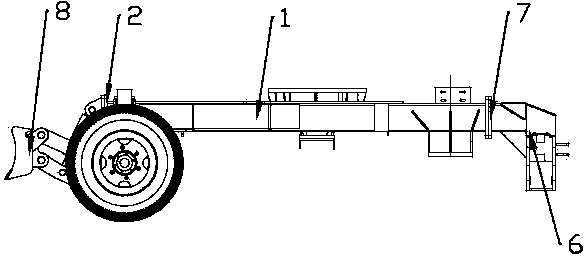

[0032] Such as Figure 3-6 As shown, the chassis of a split wheel excavator of the present invention includes a chassis main frame 1, and a connecting flange 2 connecting the chassis main frame 1 with the chassis main frame 1 is provided at the front end and the rear end of the chassis main frame 1. The periphery of the flange 2 is provided with a plurality of screw holes 3 for connecting functional accessories.

[0033] The functional accessory connected to the front end of the chassis main frame 1 is a front push shovel system 8, which is provided with a push shovel base plate 9, and the periphery of the push shovel base plate 9 is provided with screw holes and is connected with the main chassis. The screw holes on the connecting flange 2 at the front end of the frame 1 correspond to each other, and the two are connected by bolts.

[0034] The functional accessory connected to the rear end of the chassis main frame 1 is the rear support leg system 6, the rear support leg sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com