Low-cost integrated steam turbine lubricating oil system for power station auxiliary equipment

A steam turbine, low-cost technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as the time that the equipment is put into use, the connection strength is not high, and the installation workload is large, so as to reduce the on-site debugging work, The effect of reducing installation workload and ensuring equipment availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

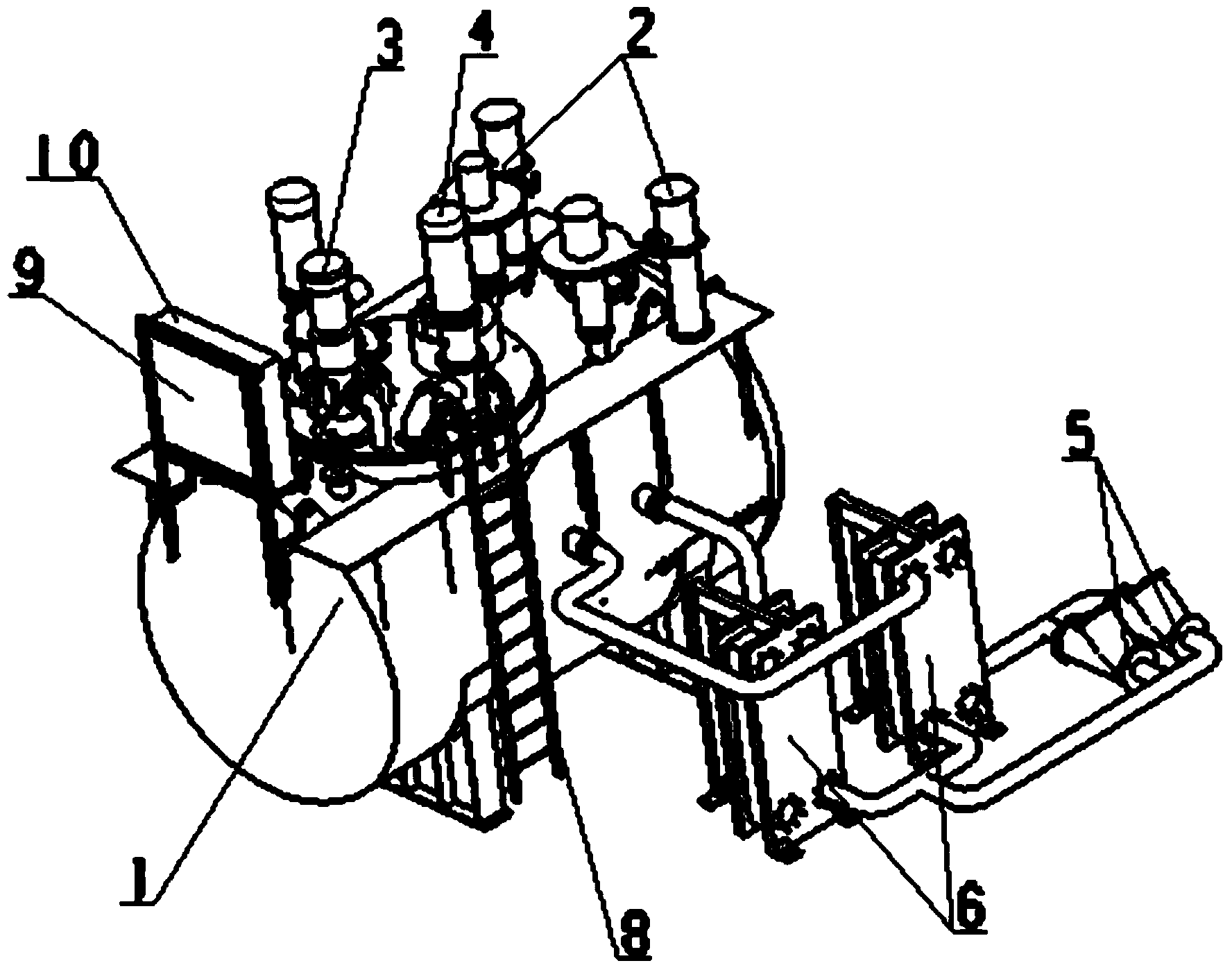

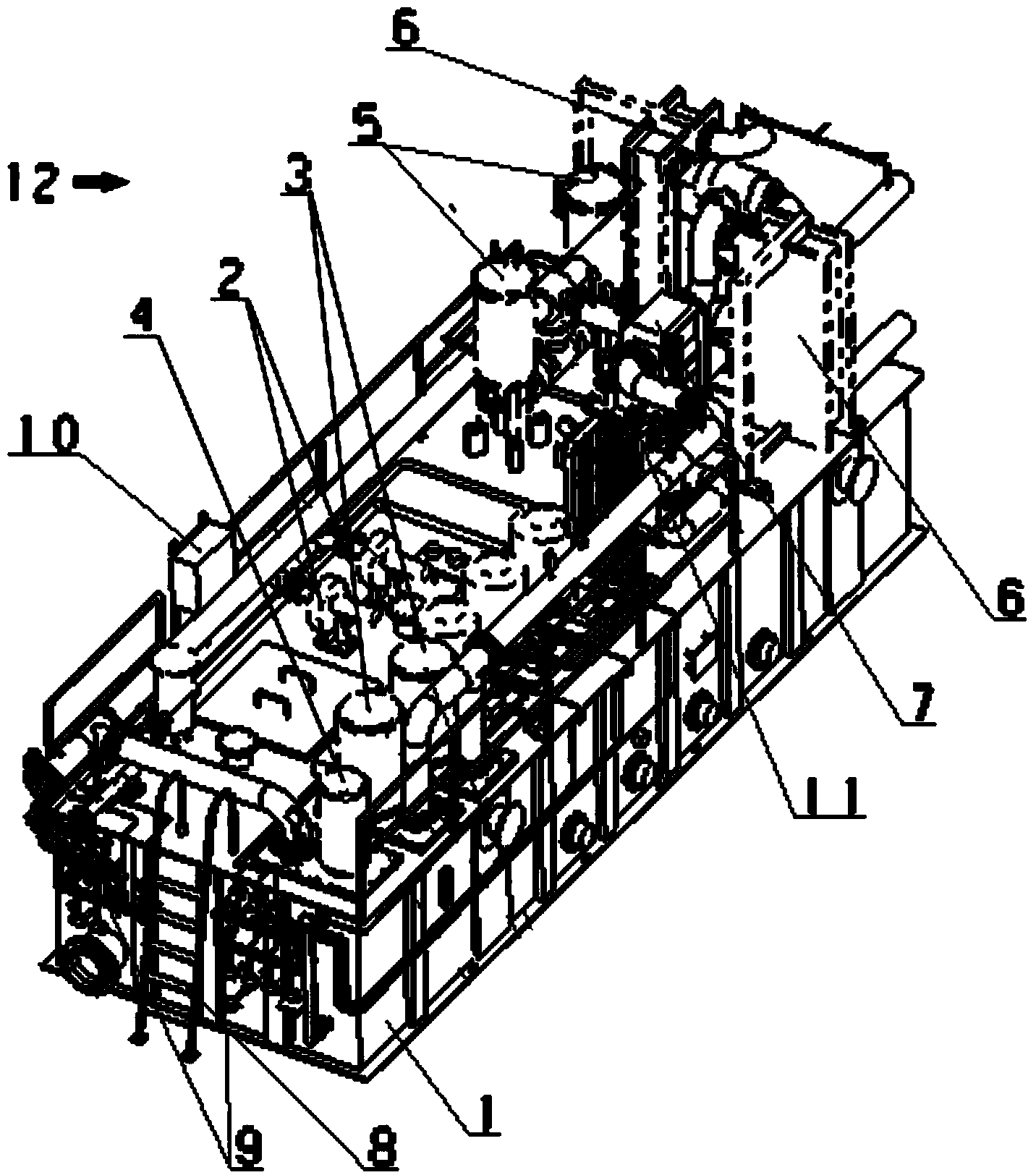

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0020] like figure 2 As shown, the steam turbine lubricating oil system includes an oil tank 1 , a bearing oil supply part 12 , a jacking shaft oil supply part 11 and an oil fume purification and discharge device 2 .

[0021] The bearing oil supply part 12 includes at least one AC lubricating oil pump 3, a DC emergency oil pump 4, a filter 5, an oil cooler 6, and a temperature control valve 7. In this embodiment, there are two AC lubricating oil pumps 3, and one is in a normal working state , and the other is in the standby state. When one AC lubricating oil pump 3 fails, the AC lubricating oil pump 3 in the standby state starts. When both AC lubricating oil pumps 3 fail, the DC emergency oil pump 4 starts to fully ensure the system. normal operation. The temperature control valve 7 is a three-way temperature control valve, the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com