Combustible direct power machine

A power machine and direct technology, applied in the field of engine equipment and combustible gas direct power machine, can solve the problems of high price, difficulty in large-scale, factoryization, and high maintenance cost, and achieve the effect of high use value, low manufacturing cost and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

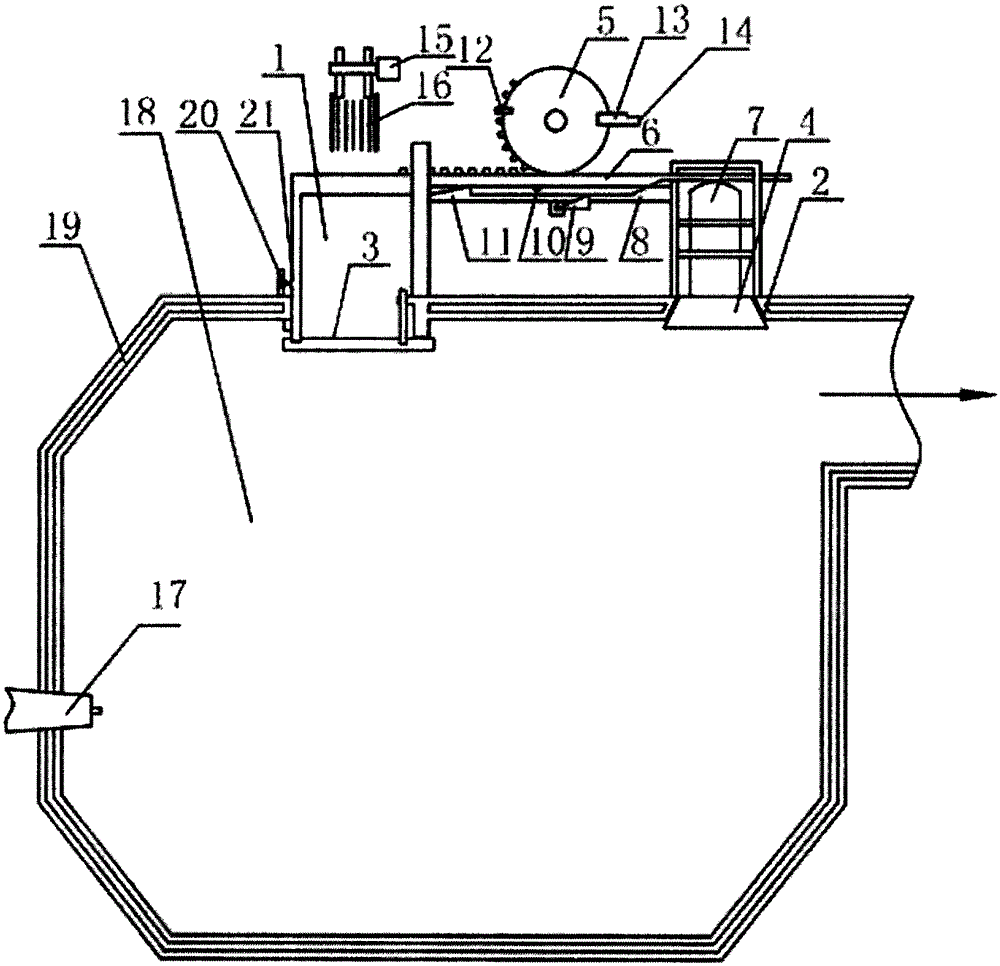

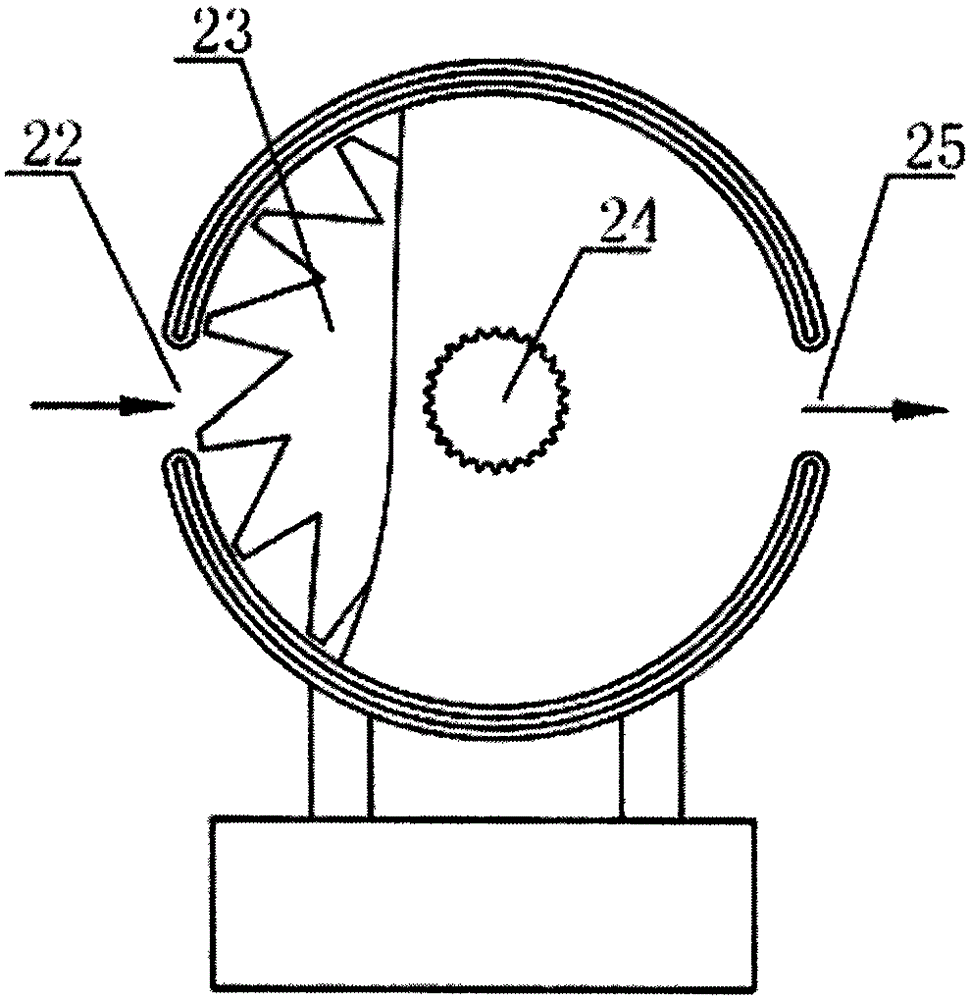

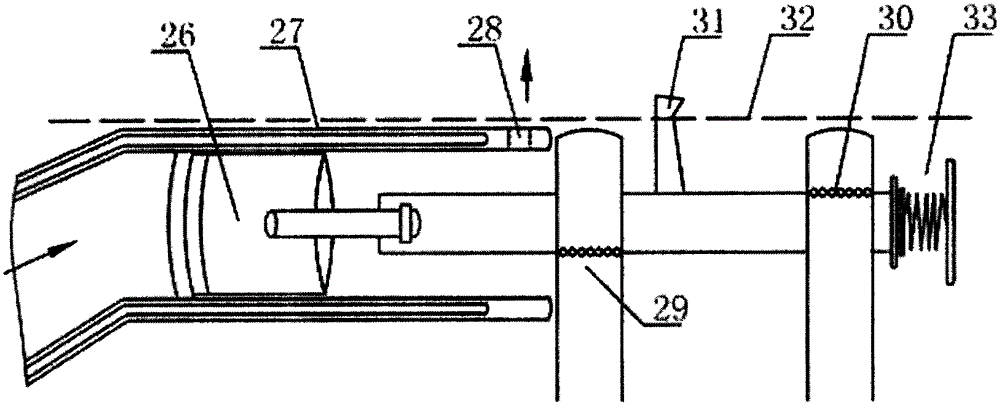

[0024] As can be seen from the accompanying drawings, the present invention specifically relates to a power plant, which is used to directly convert biomass combustible gas into a power machine for mechanical energy. The power machine specifically includes a combustion chamber 18, a ventilation system, a power output device and a spark plug 17. It is a double-layer structure, the outer layer of which is a closed water jacket, the ventilation system is placed on one side of the combustion chamber 18, the spark plug 17 passes through the side wall of the combustion chamber 18, and the power output device is connected to the outlet of the combustion chamber 18.

[0025] attached by figure 1 It can be seen that the ventilation system in the present invention includes an air intake mechanism, an exhaust mechanism and a synchronous drive mechanism. The air intake mechanism includes an air inlet 1 and a nozzle 16 placed directly above the air inlet 1. There is an intake valve 3 hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com