Method for detecting electrical conductivity of small number of solids

A conductive, solid technology, applied in the field of detection of trace solid conductivity, can solve the problems of difficulty in distinguishing volume conductivity or surface conductivity, difficulty in sample recovery, and high cost, to expand coverage, easy to carry, and cost of detection small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

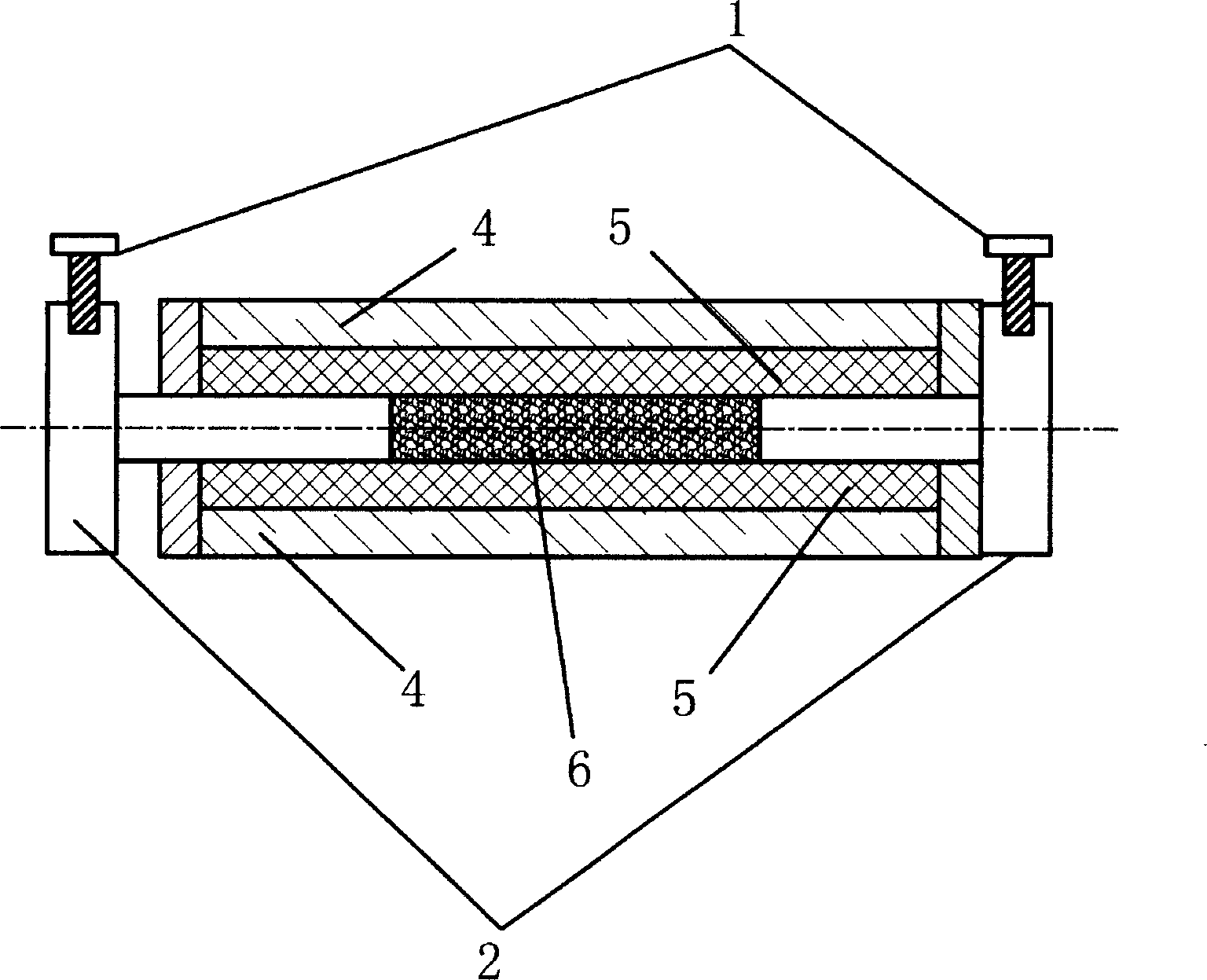

[0018] As shown in the figure, a method for detecting the conductivity of a trace solid comprises the following steps:

[0019] (a) Confining the detection powder 6 to a height of 1 to 3 centimeters and a polytetrafluoroethylene pressure tube 5 with a diameter of 3 to 5 millimeters with two metal nail electrodes 2;

[0020] (b) When measuring, apply pressure to the metal nail-shaped electrodes 2 at both ends, discharge the air between the powders, and squeeze them into a cylindrical shape;

[0021] (c) The length of the internal sample cylinder can be measured by the measuring tool, and the overall resistance can be measured by a multimeter. This value minus the electrode resistance value is the resistance value of the sample cylinder;

[0022] (d) Calculate the conductivity, the resistance value of the sample cylinder is divided by its volume to obtain its volume conductivity;

[0023] (e) After the measurement is completed, pull out the metal nail-shaped electrodes 2 from b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com