A kind of equipment for inoculating liquid strains of edible fungi in bottles

A technology of liquid strains and edible fungi, which is applied in the field of biological sciences, can solve problems affecting work efficiency, lower sterility, poor sealing, etc., and achieve the effects of improving work efficiency, reducing labor costs, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

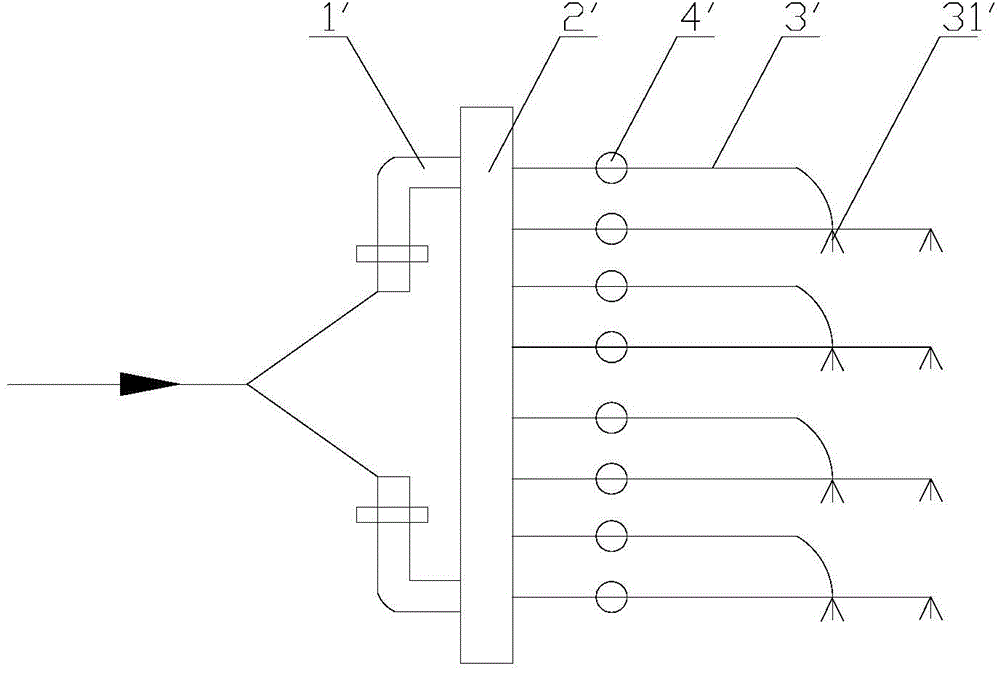

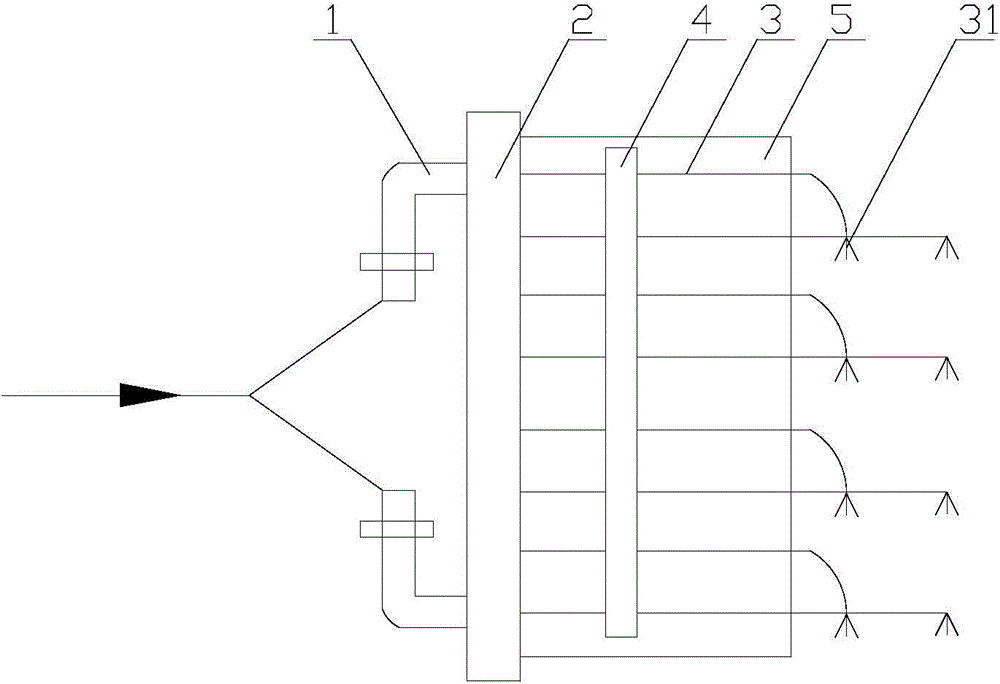

[0040] The core of the present invention is to provide a liquid strain inoculation device for edible fungus grown in bottles. The inoculation device is controlled by a cylinder and combined with a flow limiting method of elastic nozzle deformation to replace the current limiting method of the solenoid valve in the prior art, which can enhance the efficiency of inoculation. Work stability, and can improve its sealing, avoid pollution, and ensure uniform spraying.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

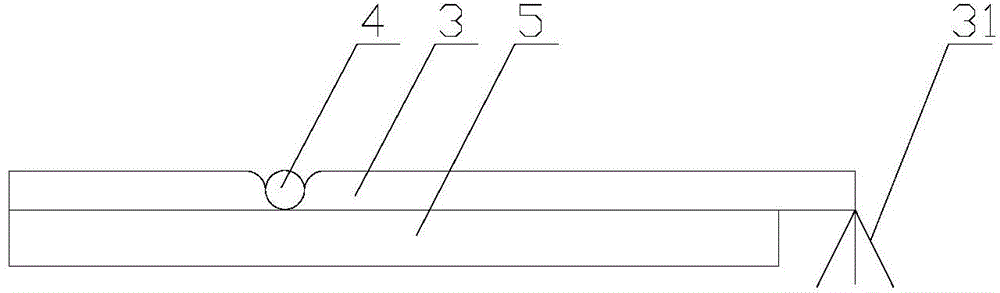

[0042] It should be noted that the "root end" herein refers to the end of the elastic nozzle 3 close to the distribution pipe 2, that is, figure 2 The left end of the middle elastic nozzle 3, "terminal" refers to the end of the elastic nozzle 3 near the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com