Ultraviolet sterilization device used for water treatment and coated with photocatalytic materials

A technology of a sterilization device and a catalytic material, which is applied in the field of water treatment, can solve the problems of poor sterilization and water treatment capacity, high energy consumption cost of consumables, and unsatisfactory sterilization efficiency, so as to save energy consumption cost of consumables, improve capacity, and improve sterilization. effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

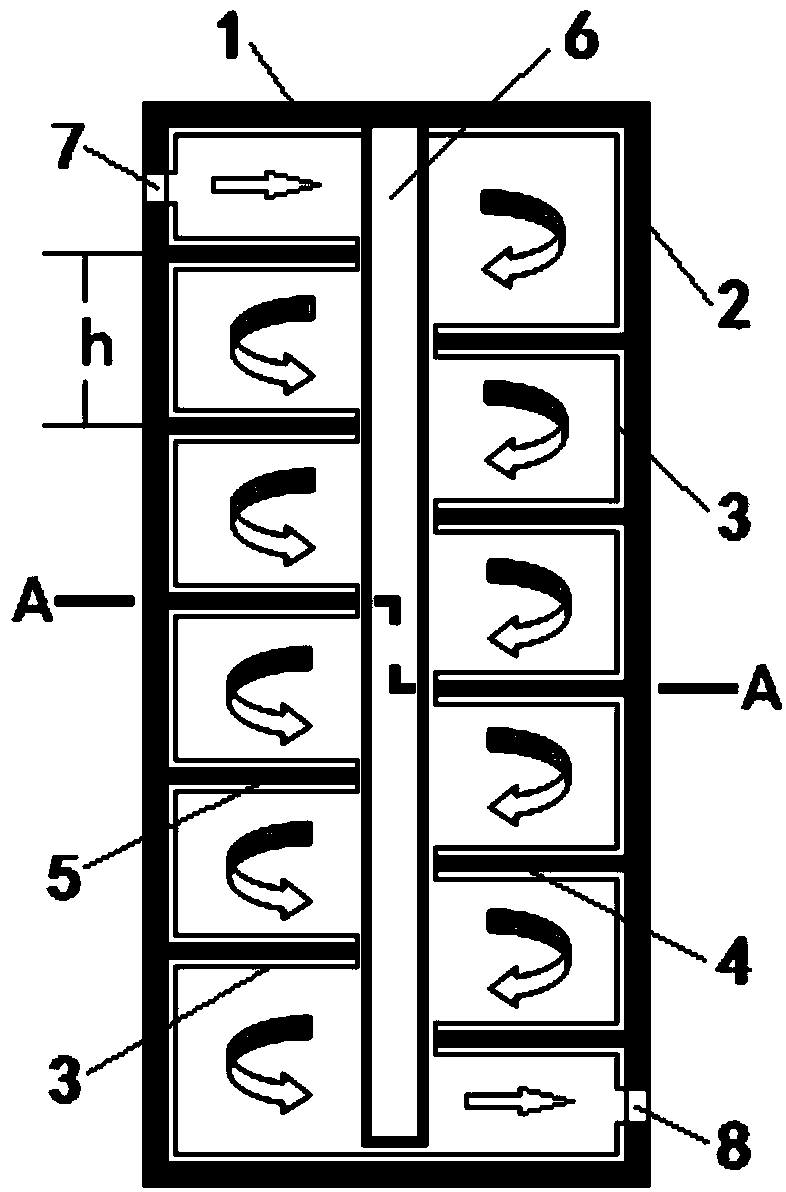

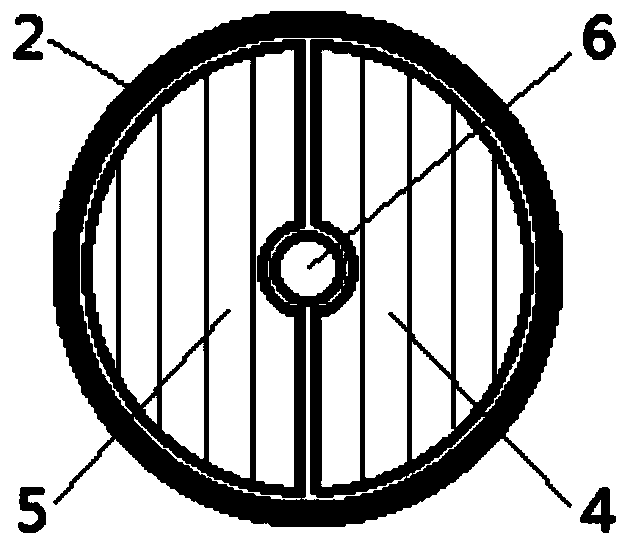

[0028] A closed cylinder is composed of a cylinder wall and a cylinder cover. Two sets of parallel and misaligned semicircular baffles are fixed on the cylinder wall. The baffles in each group are also parallel to each other. The left semicircular baffle The included angle α with the central axis and the included angle β between the right semicircular baffle and the central axis are both 90 degrees, the distance h between two adjacent baffles in each set of baffles is 50 mm, and the inner surface of the cylinder And the surface of the baffle is coated with nano-TiO 2 1. An ultraviolet lamp tube is placed on the central axis of the cylinder, and a water inlet and a water outlet are opened at both ends of the cylinder wall.

[0029] Raw water flows in from the water inlet at one end of the cylinder, and flows through the dislocation gap between two sets of parallel semicircular baffles. The photocatalytic material is sterilized on its surface after being irradiated by ultraviole...

Embodiment 2

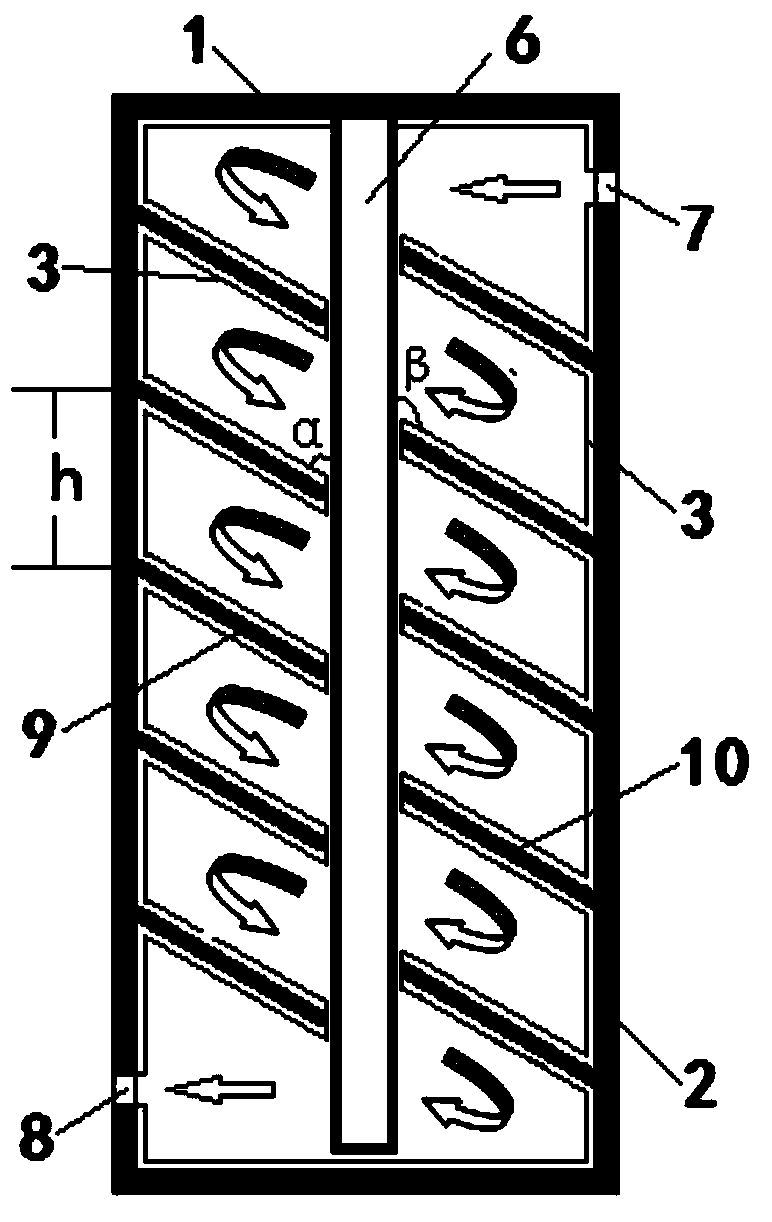

[0031] A closed cylinder is composed of a cylinder wall and a cylinder cover. Two sets of parallel and misplaced semi-elliptical baffles are fixed on the cylinder wall. The baffles in each group are also parallel to each other. The left semi-elliptical baffle The included angle α with the central axis is 60 degrees, the included angle β between the right semi-elliptical baffle and the central axis is 120 degrees, the interval h between two adjacent baffles in each group is 100 mm, and the inner surface of the cylinder And the surface of the baffle is fixedly coated with composite oxide TiO 2 -SnO 2 A reflective gasket, an ultraviolet lamp tube is placed on the central axis of the cylinder, and a water inlet and a water outlet are opened at both ends of the cylinder wall.

[0032] Raw water flows in from the water inlet at one end of the cylinder, and flows through the dislocation gap between two sets of parallel semi-elliptical baffles. The photocatalytic material is sterilized...

Embodiment 3

[0034] A closed cylinder is composed of a cylinder wall and a cylinder cover. Two sets of non-parallel and misplaced semi-elliptical baffles are fixed on the cylinder wall. The baffles in each group are parallel to each other, and the left semi-elliptical baffle The included angle α with the central axis is 60 degrees, the included angle β between the right semi-elliptical baffle and the central axis is also 60 degrees, and the interval h between two adjacent baffles in each group is 100 mm. The surface and the baffle surface are fixedly coated with composite oxide ZnO-SnO 2 A reflective gasket, an ultraviolet lamp tube is placed on the central axis of the cylinder, and a water inlet and a water outlet are opened at both ends of the cylinder wall.

[0035] Raw water flows in from the water inlet at one end of the cylinder, and flows through the dislocation gap between two sets of non-parallel semi-elliptical baffles. The photocatalytic material is sterilized on its surface aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com