Drilling lubricant, preparation of drilling lubricant, base plate adopting drilling lubricant and aluminum-based cover plate adopting drilling lubricant

A lubricant and activator technology, which is applied in the field of backing plates and aluminum-based cover plates, can solve the problems of not meeting the production quality requirements, the PCB hole wall is not smooth enough, and has no lubricating effect, so as to achieve good lubrication and smooth hole walls , The effect of reducing the broken drill rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

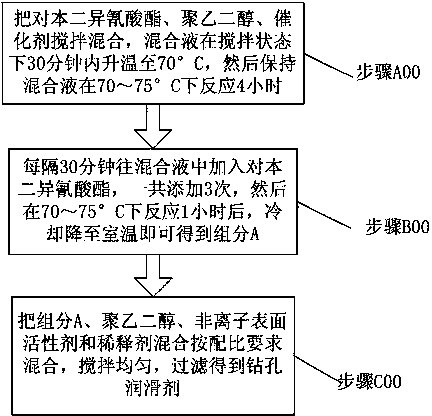

[0028] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0029] Components and weight percentages thereof that described drilling lubricant comprises are:

[0030] Component A: 20-30 parts;

[0031] Polyethylene glycol: 50-60 parts;

[0032] Non-ionic surfactant: 5-10 parts;

[0033] Thinner: 100-120 parts;

[0034] The components included in the component A and their weight percentages are: p-diisocyanate: 139 parts; polyethylene glycol: 2000 parts; catalyst: 0.2-0.3 parts.

[0035] The polyethylene glycol 2000 in the component A is polyethylene glycol with a molecular weight of 2000.

[0036] The 50-60 parts of polyethylene glycol include polyethylene glycol 6000 and polyethylene glycol 10000, that is, polyethylene glycol with a molecular weight of 6000 and polyethylene glycol with a mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com