Electrical heating crucible type low-boiling-point metal distillation furnace capable of continuously feeding material

An electric heating and distillation furnace technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of continuous feeding and distillation, serious environmental pollution, low energy efficiency, etc., and achieves convenient operation, low energy consumption, product high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

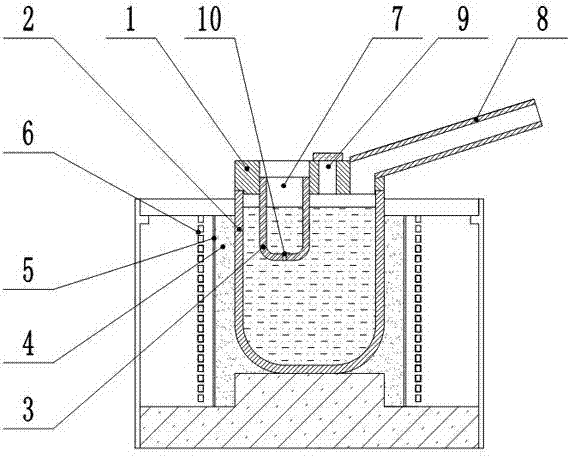

[0008] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

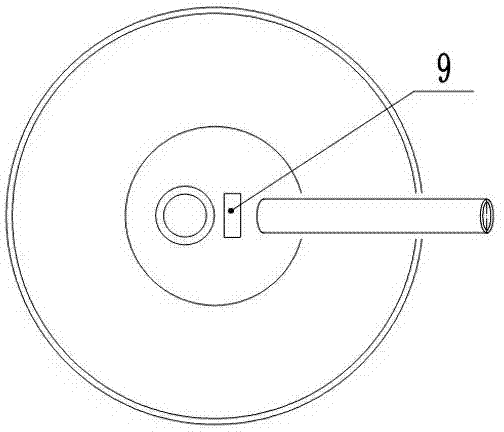

[0009] As shown in the figure, an electric heating crucible-type low-boiling point metal distillation furnace capable of continuous feeding includes a clay graphite distillation crucible 2 with a top cover 1 made of refractory castables, a clay graphite melting crucible 3, and a distillation crucible 2 crucibles. The body is coated with high-alumina refractory insulation layer 4, asbestos layer 5, coreless induction furnace coil 6 in turn, and the upper cover 1 is provided with a feeding port 7, a steam output conduit 8, and a slag cleaning port 9, and the feeding port on the upper cover 1 7. The lower end is connected to the upper port of the melting crucible 3. There is a discharge hole 10 at the bottom of the melting crucible 3, and the bottom of the crucible is 300mm from the upper edge of the upper cover 1 of the distillation crucible 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com