Construction method for reserved laterally widened structure of underground box culvert structure

A technology of structural construction and box culverts, which is applied in the direction of earthwork drilling, road bottom layer, mining equipment, etc., which can solve the problems of increased construction difficulty, construction period and construction risks, difficulty in adjusting support positions, and difficulty in bearing the supporting axial force on the side walls of box culverts and other issues to achieve the effect of reducing construction risk and difficulty, simple and convenient construction, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Below in conjunction with accompanying drawing this method is described further, and its implementation method step is as follows:

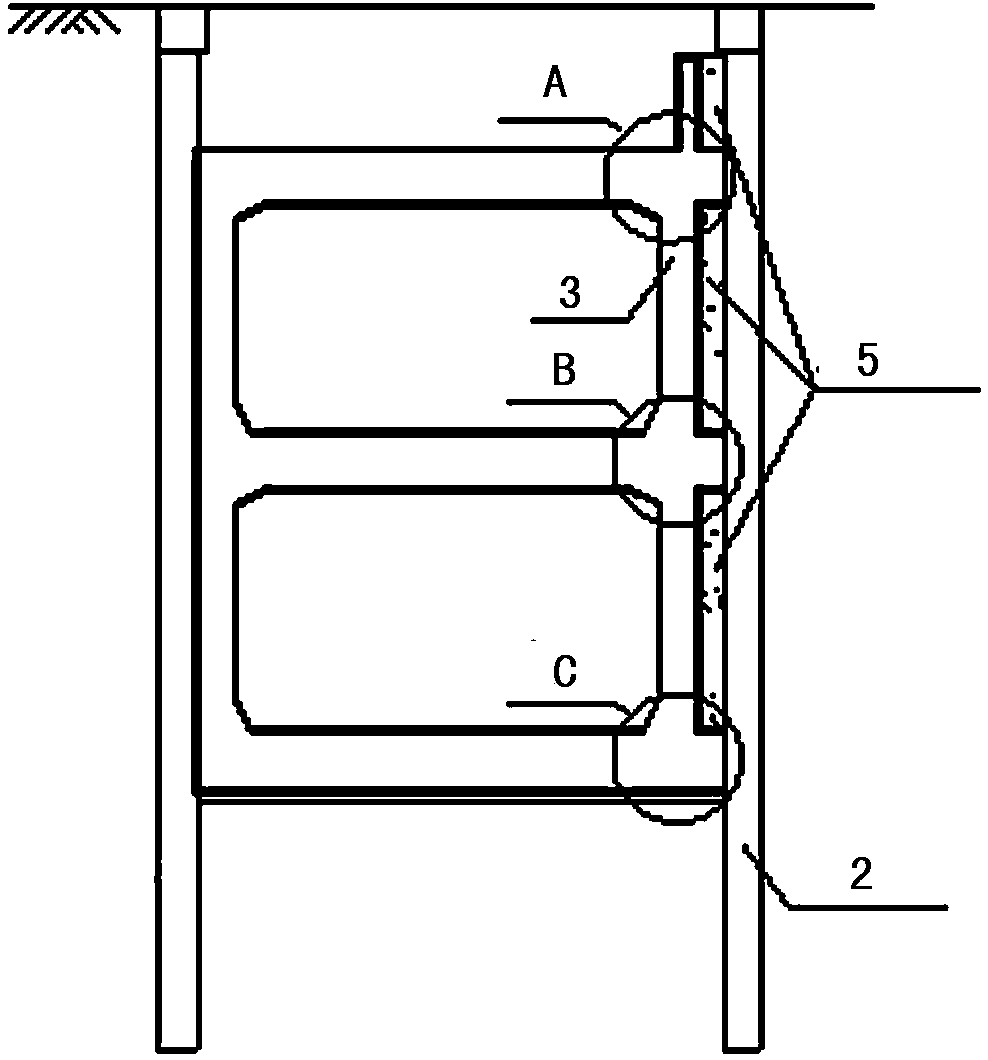

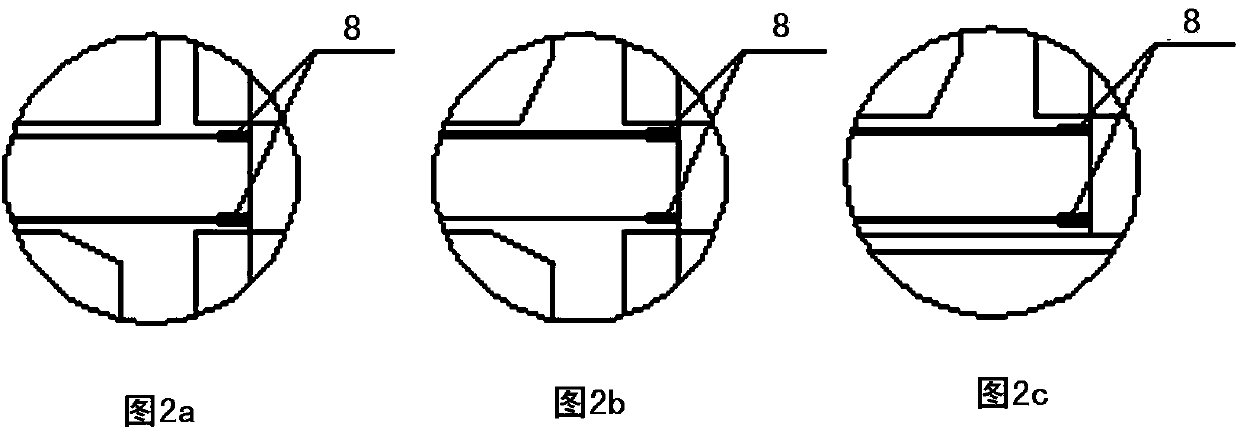

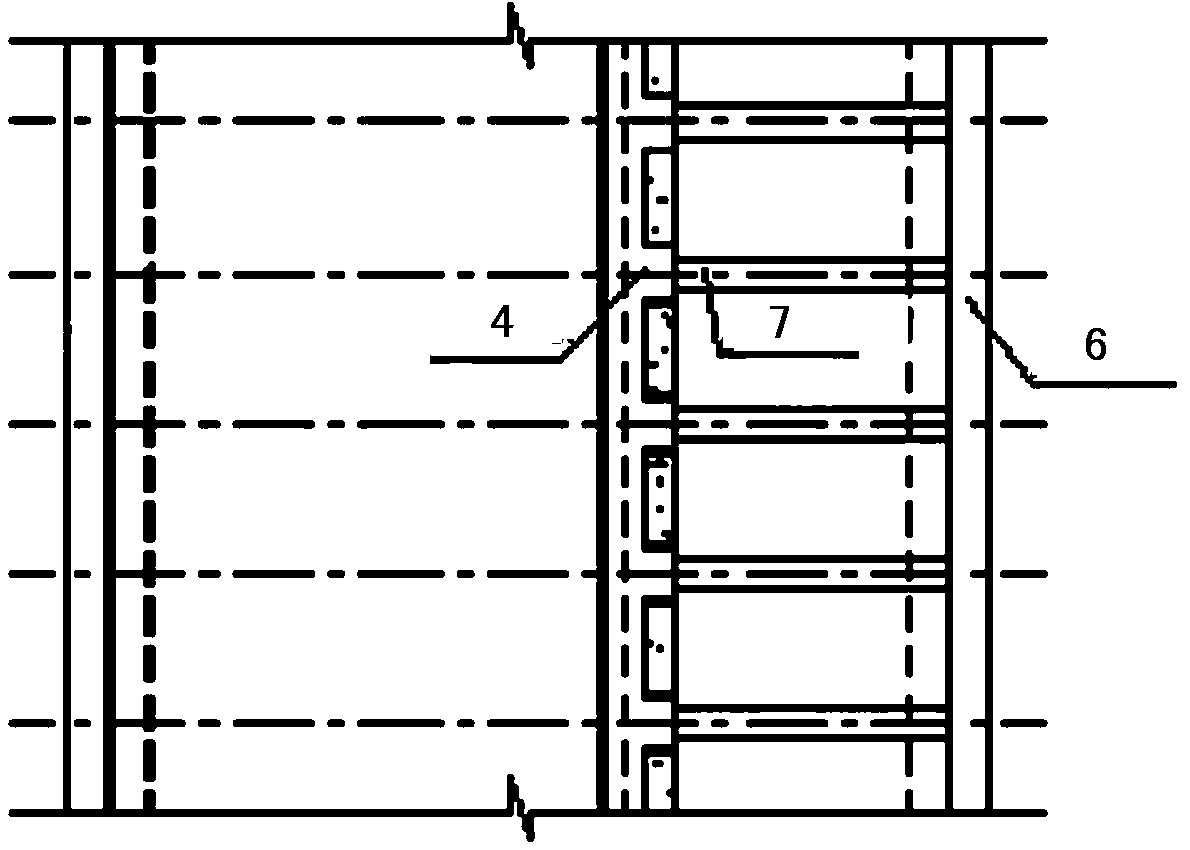

[0023] A. The widened side walls of the underground box culvert structure implemented in the early stage of construction. On the side that needs to be widened, the enclosure structure 2 is separated from the internal box culvert structure, that is, the steel bars and the enclosure structure such as the underground diaphragm wall are not connected. The top plate 10, the middle plate 11, and the bottom plate 12 pick out the side wall 3 of the box culvert and extend it to the enclosure structure 2 built first, and reserve the top, middle, and bottom plate steel bar connectors 8 needed to connect the box culvert later (see figure 1 with figure 2 ), the distance between the side wall and the building envelope 2 is gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com