Ultra-low temperature heat source engine

An engine and ultra-low temperature technology, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of serious pollution and emission, and achieve the effect of simple structure and high power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

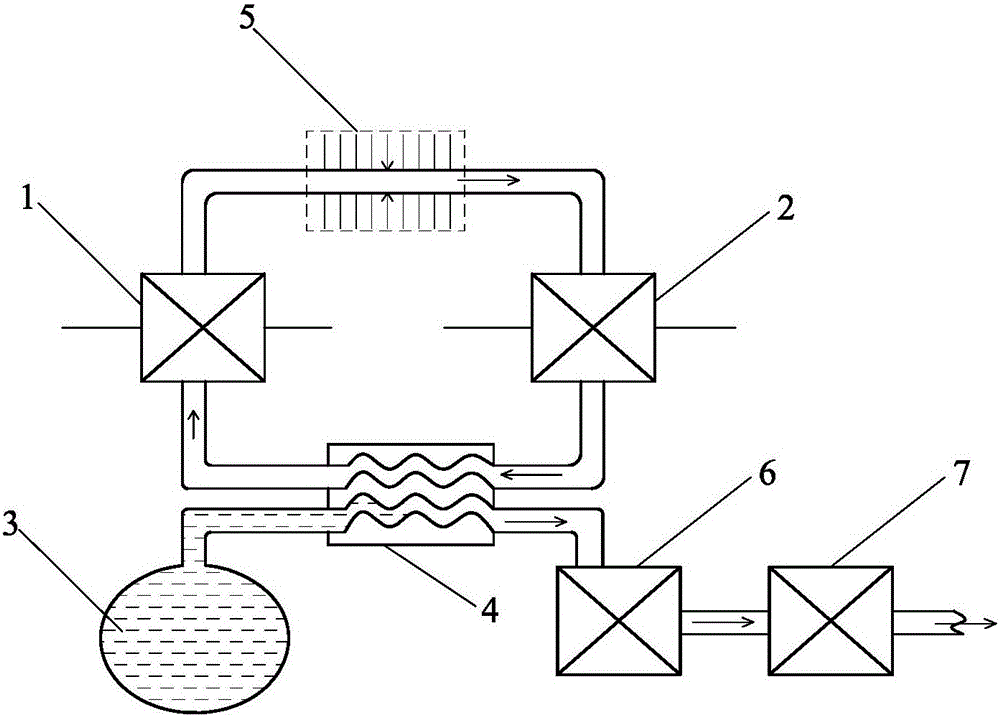

[0043] Such as figure 1 The shown ultra-low temperature heat source engine includes a gas compression mechanism 1, a gas work mechanism 2 and a gas liquefied substance source 3, and the working medium outlet of the gas compression mechanism 1 communicates with the working medium inlet of the gas work mechanism 2 through a heater 5 The working medium outlet of the gas working mechanism 2 communicates with the working medium inlet of the gas compression mechanism 1 through the cooled fluid channel of the heat exchanger 4, and the gas liquefied source 3 passes through the cooled fluid channel of the heat exchanger 4 The heating fluid passage communicates with the working fluid inlet of the auxiliary heater 6 , and the working fluid outlet of the auxiliary heater 6 communicates with the auxiliary gas working mechanism 7 .

[0044] In this embodiment, the working fluid circulating in the closed loop including the gas working mechanism 2 and the gas compression mechanism 1 is set a...

Embodiment 2

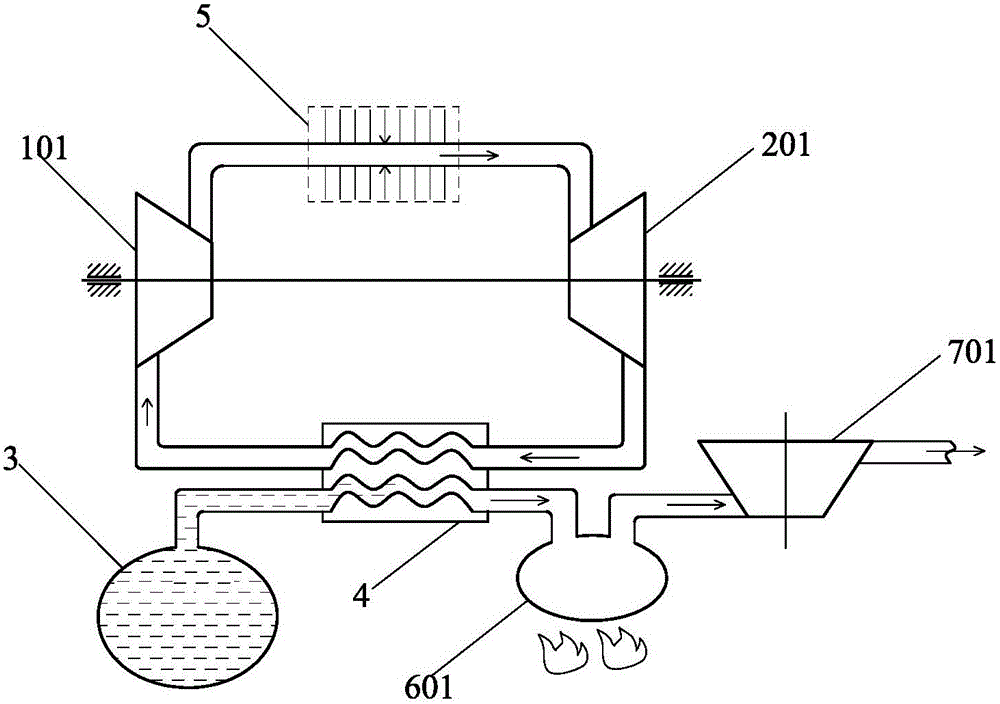

[0048] Such as figure 2 The shown ultra-low temperature heat source engine, on the basis of Embodiment 1: the gas compression mechanism 1 is set as an impeller-type gas compression mechanism 101, the gas working mechanism 2 is set as an impeller-type gas working mechanism 201, and the impeller-type The gas working mechanism 201 is provided in conjunction with the impeller-type gas compression mechanism 101 , the auxiliary heater 6 is an external combustion heater 601 , and the auxiliary gas working mechanism 7 is an impeller-type auxiliary gas working mechanism 701 .

Embodiment 3

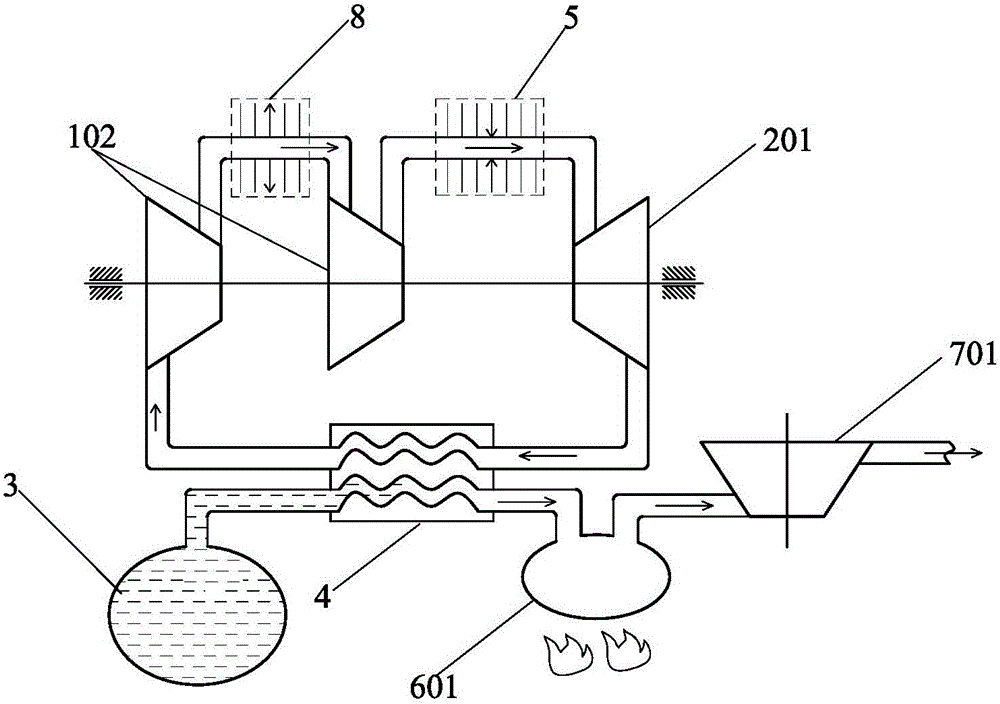

[0050] Such as image 3 The difference between the shown ultra-low temperature heat source engine and Embodiment 2 is that the gas compression mechanism 2 is changed to a two-stage impeller type gas compression mechanism 102, and cooling is provided between the stages of the two-stage impeller type gas compression mechanism 102. device 8.

[0051] As a changeable embodiment, the gas compression mechanism 2 can also be changed to three or more stages; the cooler 8 can be set on a one-stage impeller type gas compression mechanism.

[0052] As a changeable embodiment, in all embodiments of the present invention, the gas compression mechanism 1 can be selectively set as a multi-stage gas compression mechanism with reference to this embodiment. Similarly, the gas work mechanism 2 can be selected It is permanently set as a multi-stage gas work mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com