Supplementary combustion lithium bromide absorption heat exchange system

A lithium bromide absorption and heat exchange system technology, which is applied in the field of air conditioning equipment, can solve the problems of waste of heat supply capacity of the heating pipe network, and achieve the effects of improving heat supply capacity, improving the effective use of temperature difference, and increasing the amount of extraction and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

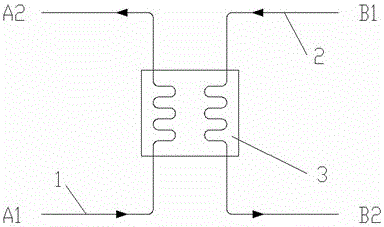

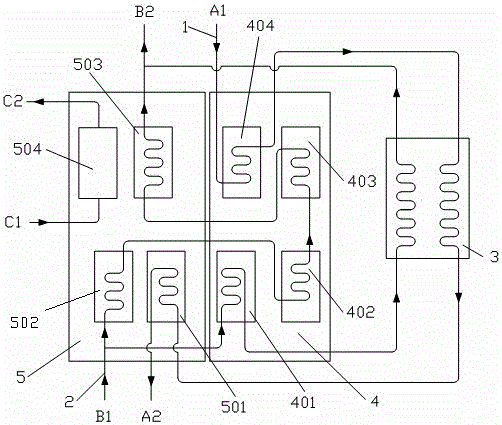

[0017] figure 2 It is a diagram of an application example of the supplementary combustion type lithium bromide absorption heat exchange system involved in the present invention. The system consists of a primary network hot water pipeline system 1, a secondary network hot water pipeline system 2, a heat exchanger 3, a hot water lithium bromide absorption unit 4 and a direct-fired lithium bromide absorption unit 5. The hot water lithium bromide absorption unit 4 includes an evaporator 401 , an absorber 402 , a condenser 403 and a generator 404 . The direct-fired lithium bromide absorption unit 5 includes an evaporator 501 , an absorber 502 , a condenser 503 and a generator 504 . The primary network hot water coming from the primary network hot water pipeline system 1 first enters the generator 404 of the hot water type lithium bromide absorption unit 4 as the driving heat source for primary cooling, then enters the heat exchanger 3 for secondary cooling, and finally enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com