Sensor for active leveling detection of nanoimprint lithography working tables

A detection sensor and nano-imprinting technology, which is applied in the direction of instruments, measuring devices, and optical devices, can solve the problems of high installation and positioning accuracy, difficult implementation, and increased cost of active-adjustable nano-imprinting workbenches. Achieve the effects of eliminating system errors, saving installation and adjustment workload, and reducing manufacturing and testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

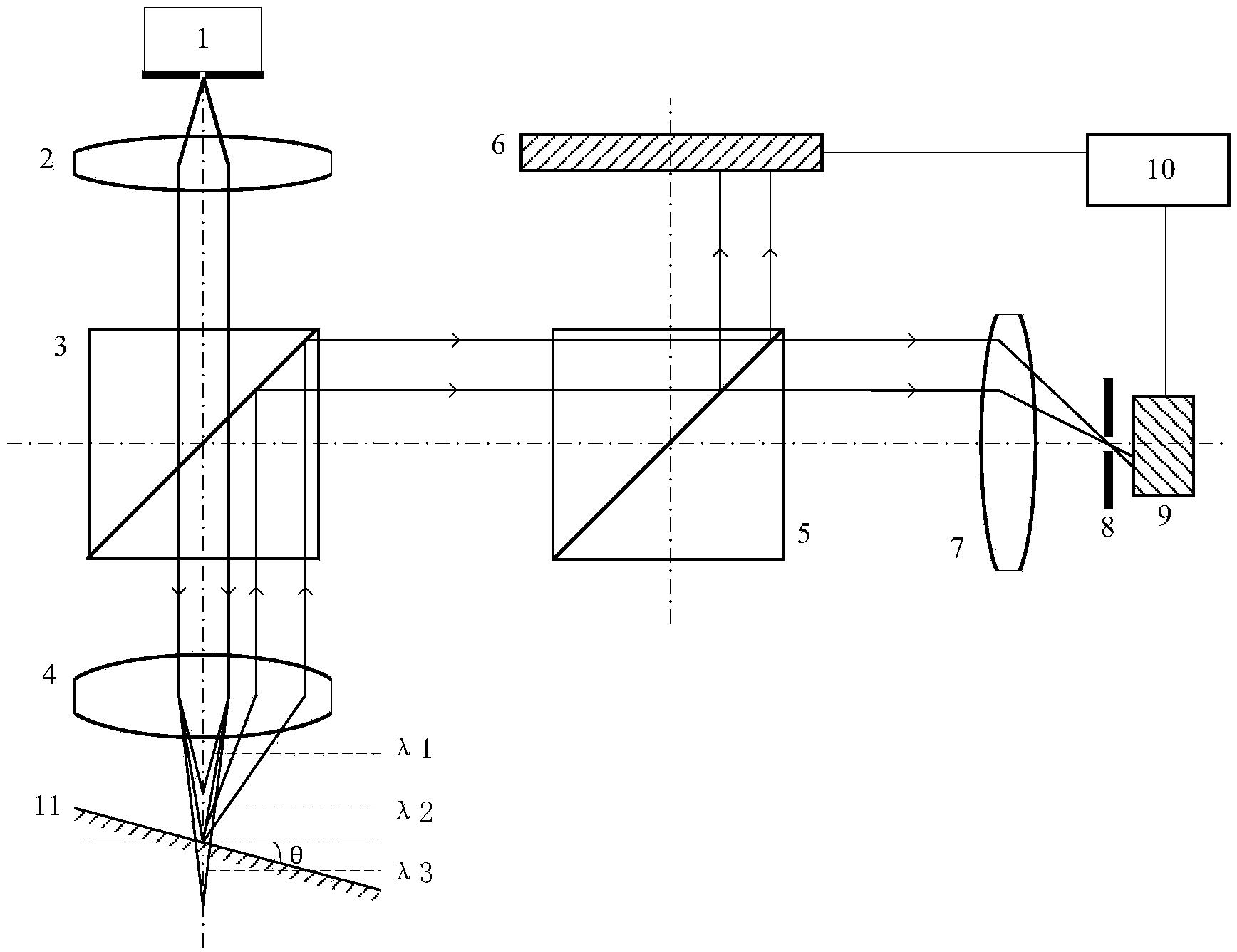

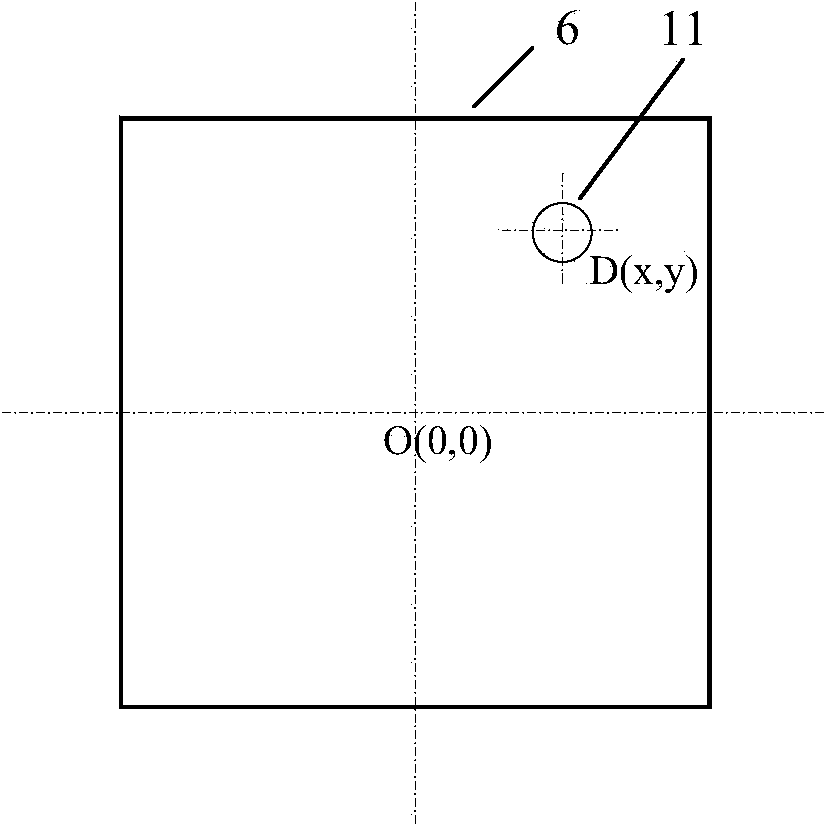

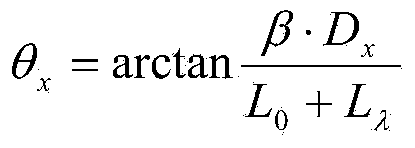

[0022] refer to figure 1 , an active leveling detection sensor for a nanoimprint worktable, including a broadband point light source 1, the light emitted by the broadband point light source 1 passes through the first achromatic beam expander and collimator optical lens 2 to form a broadband parallel beam, and the light of different wavelengths There is no phase difference; the parallel light enters the dispersion lens group 4 after passing through the first dichroic prism 3, and the light of different wavelengths produces spectral dispersion, forming a series of focal points in space; a certain monochromatic light focused on the surface of an inclined object passes through the substrate 11 Reflected by the dispersive lens group 4, the outgoing parallel monochromatic light beam is equal to the incident light and has an optical axis offset; the monochromatic parallel l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com