Phase identification method for vanadium slag rich in various impurity elements

An identification method and a technology for impurity elements, which are applied in the field of vanadium slag phase identification, can solve problems such as no vanadium slag phase identification method, and achieve the effect of broad industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

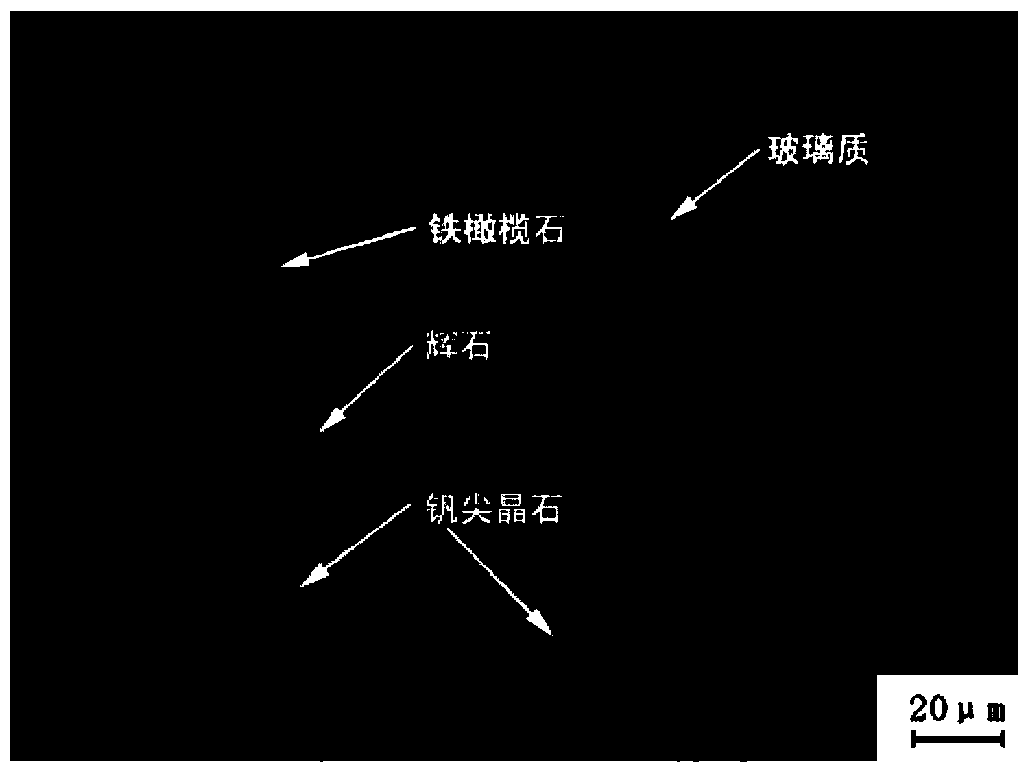

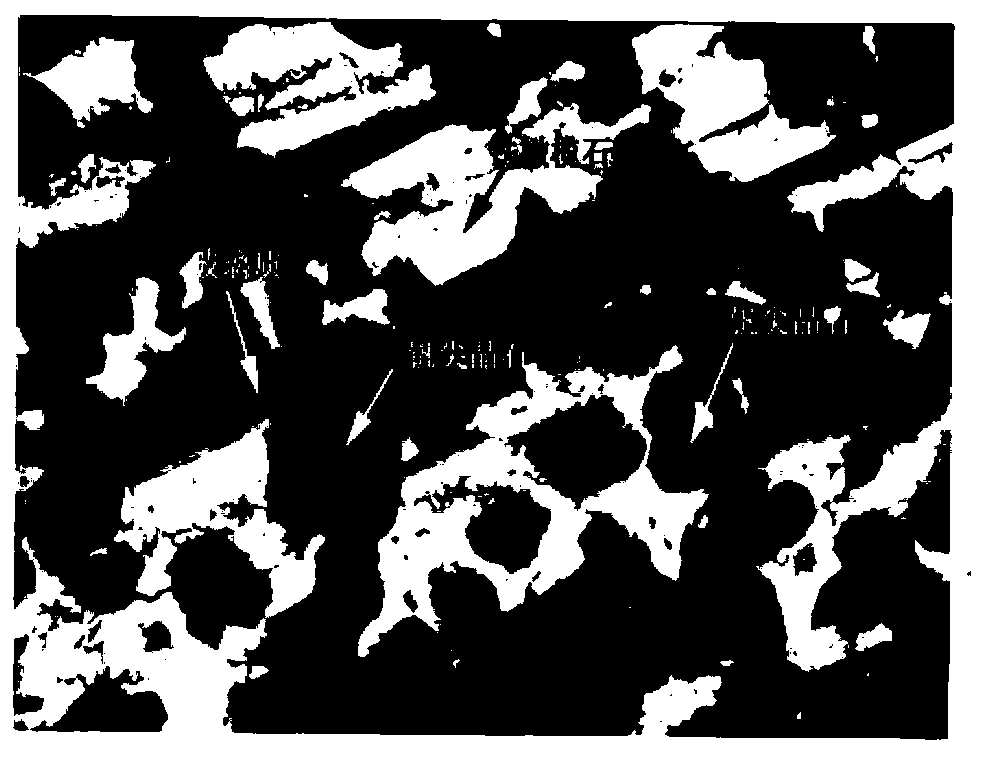

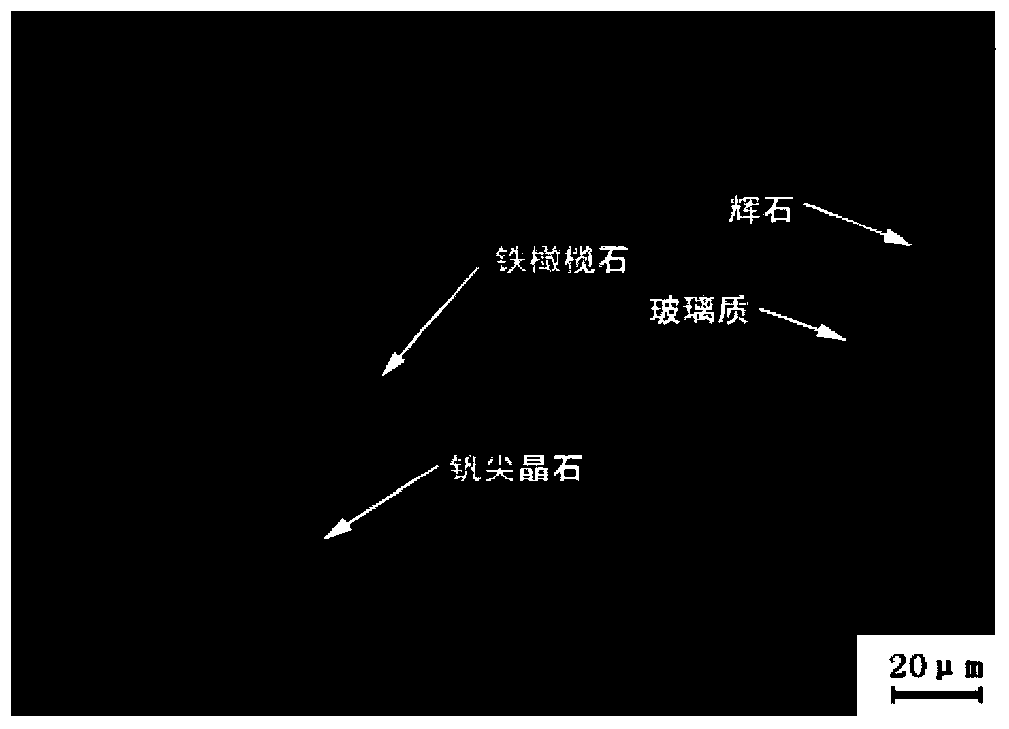

[0020] Hereinafter, an exemplary embodiment of the phase identification method of vanadium slag rich in various impurity elements according to the present invention will be described in detail.

[0021] The phase identification method of vanadium slag rich in various impurity elements according to the present invention includes the following steps A to H performed in sequence. The method of the present invention can be used for phase identification of vanadium slag produced with vanadium-titanium magnetite as raw material, but the method of the present invention is not limited thereto. phase identification.

[0022] According to an exemplary embodiment of the present invention, the phase identification method of vanadium slag rich in various impurity elements includes the following steps.

[0023] Step A:

[0024] The vanadium slag is pretreated to obtain a vanadium slag standard sample.

[0025] In step A, in order to ensure the validity and guiding role of the identific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com