Capacitive equipment partial discharge detection method based on optical fiber current sensor

A partial discharge detection, optical fiber current technology, applied in the direction of instruments, testing dielectric strength, electrical digital data processing, etc., can solve the problems of small application range, poor anti-interference ability, low reliability, etc., to overcome the poor anti-interference ability , good anti-interference ability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

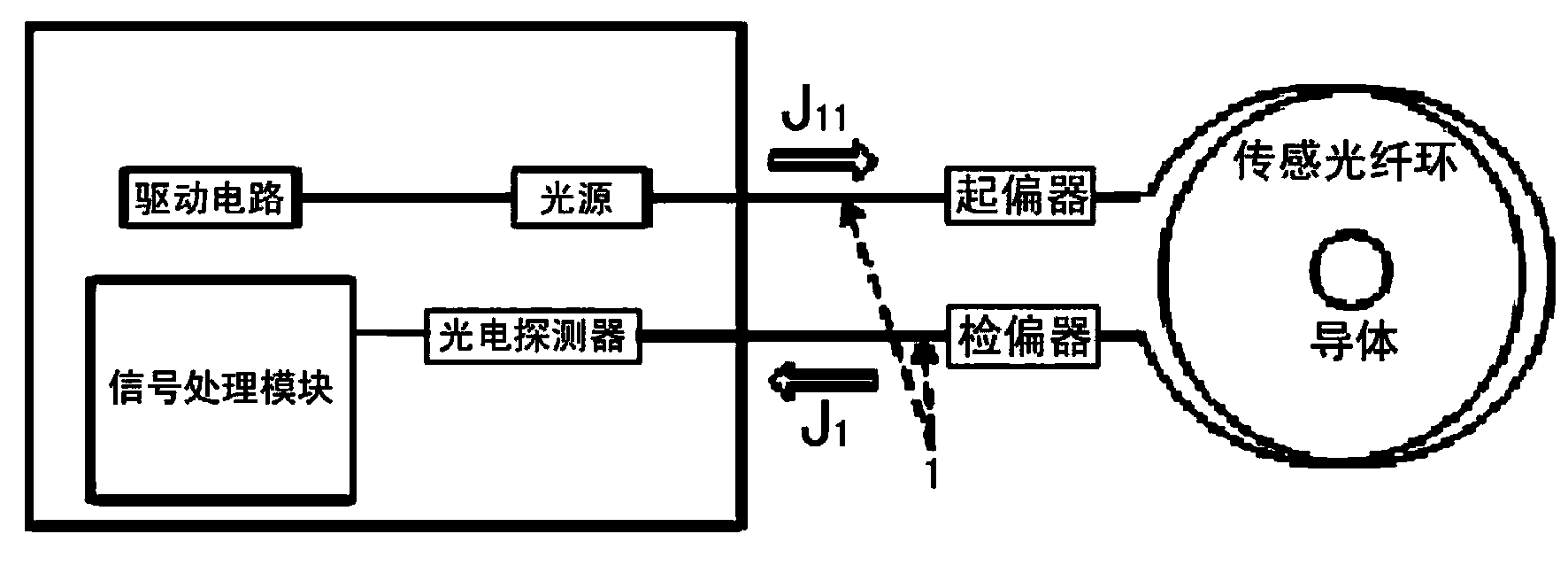

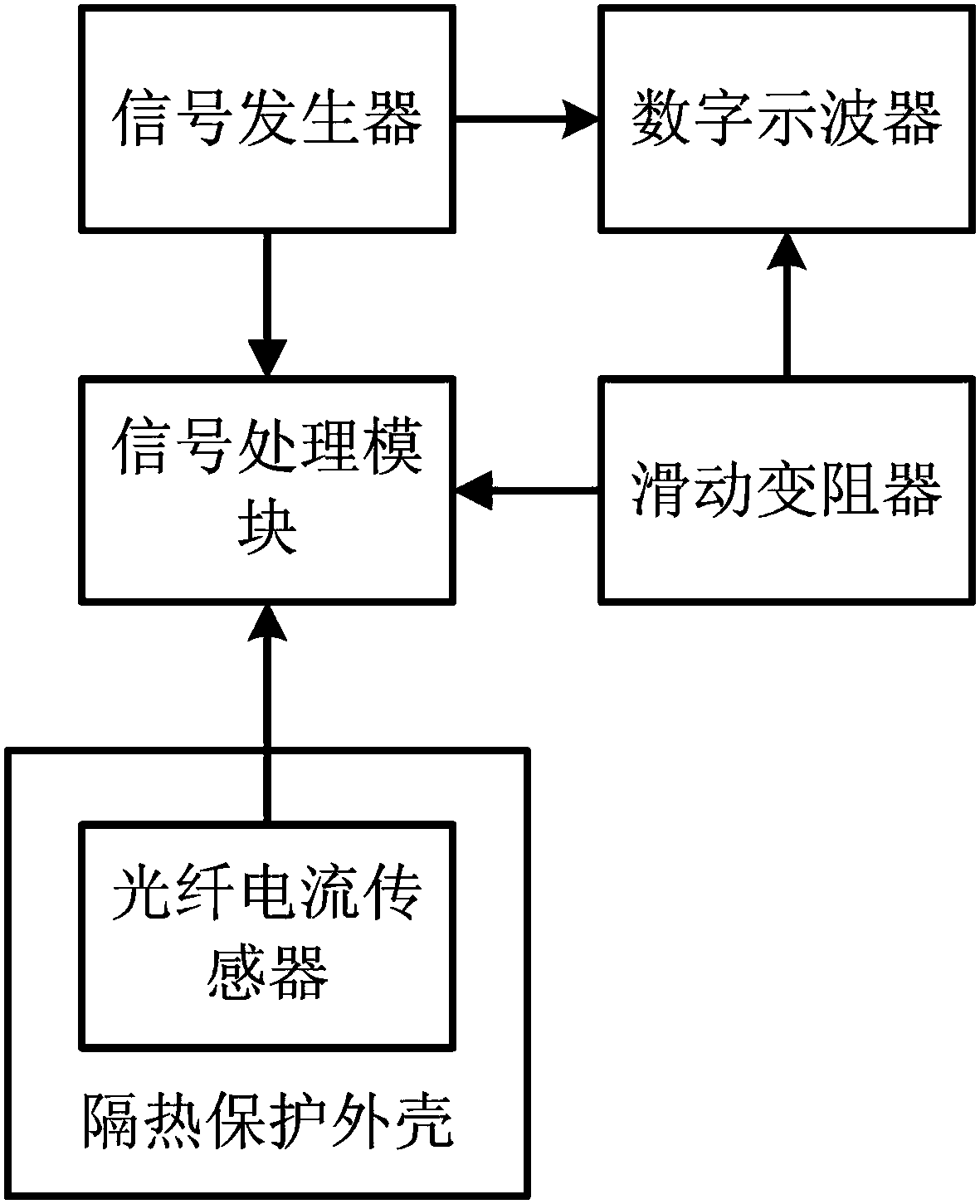

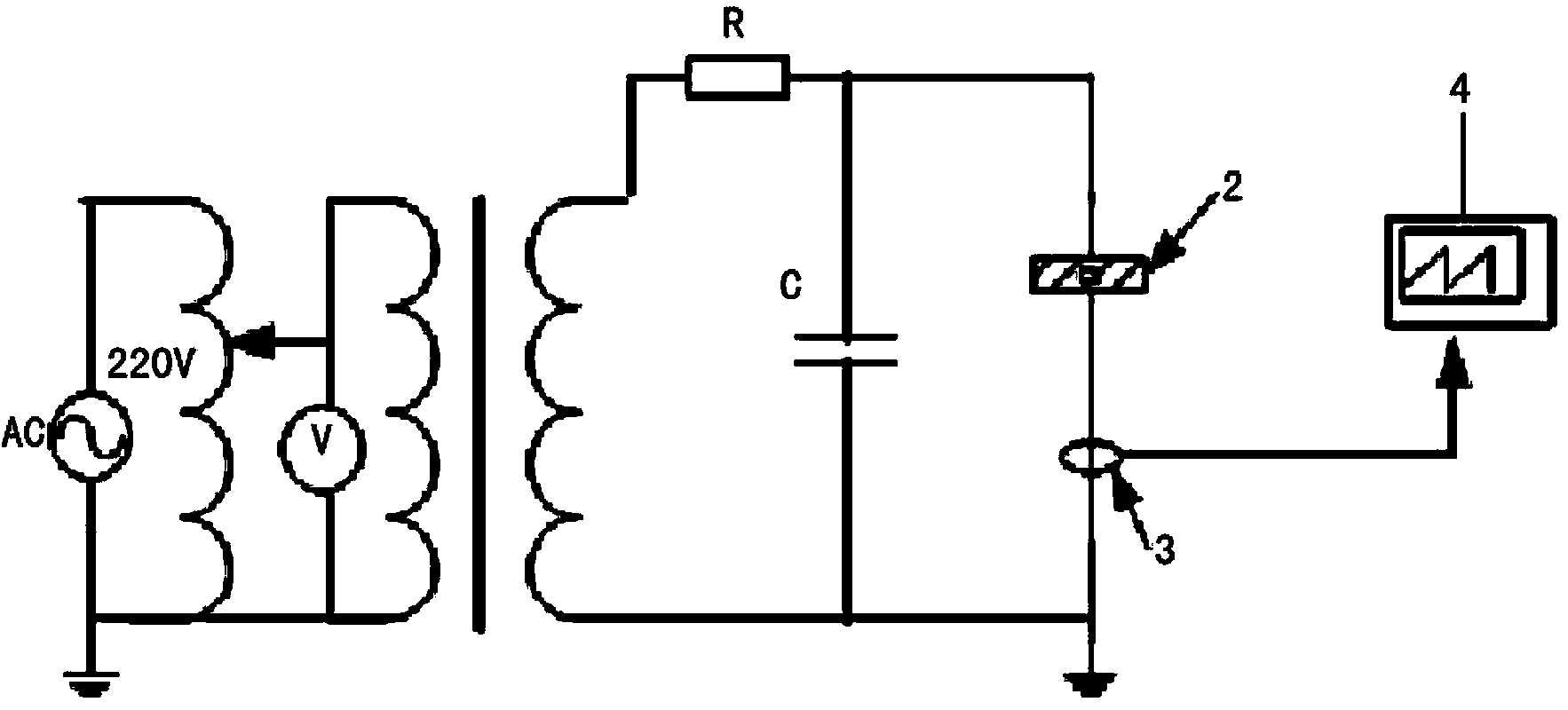

[0051] Since the discharge pulse energy is small and has certain randomness, and some interference signals are many times larger than the discharge signal of the device itself, this seriously affects the sensitivity of the test and the reliability of the detection, so it is necessary to develop a high-performance sensor. The corresponding Jones matrix is deduced for the optical device involved in the present invention, and the mathematical model of the optical fiber current sensor is established. The partial discharge current signal has the characteristics of wide frequency distribution and weak amplitude. It is necessary to develop a broadband high-frequency fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com