Manufacturing method of capacitive touch screen

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., can solve the problems that capacitive touch screen cannot meet the demand and cannot make curved surface, so as to prevent circuit breakage and improve Yield rate and the effect of avoiding disconnection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

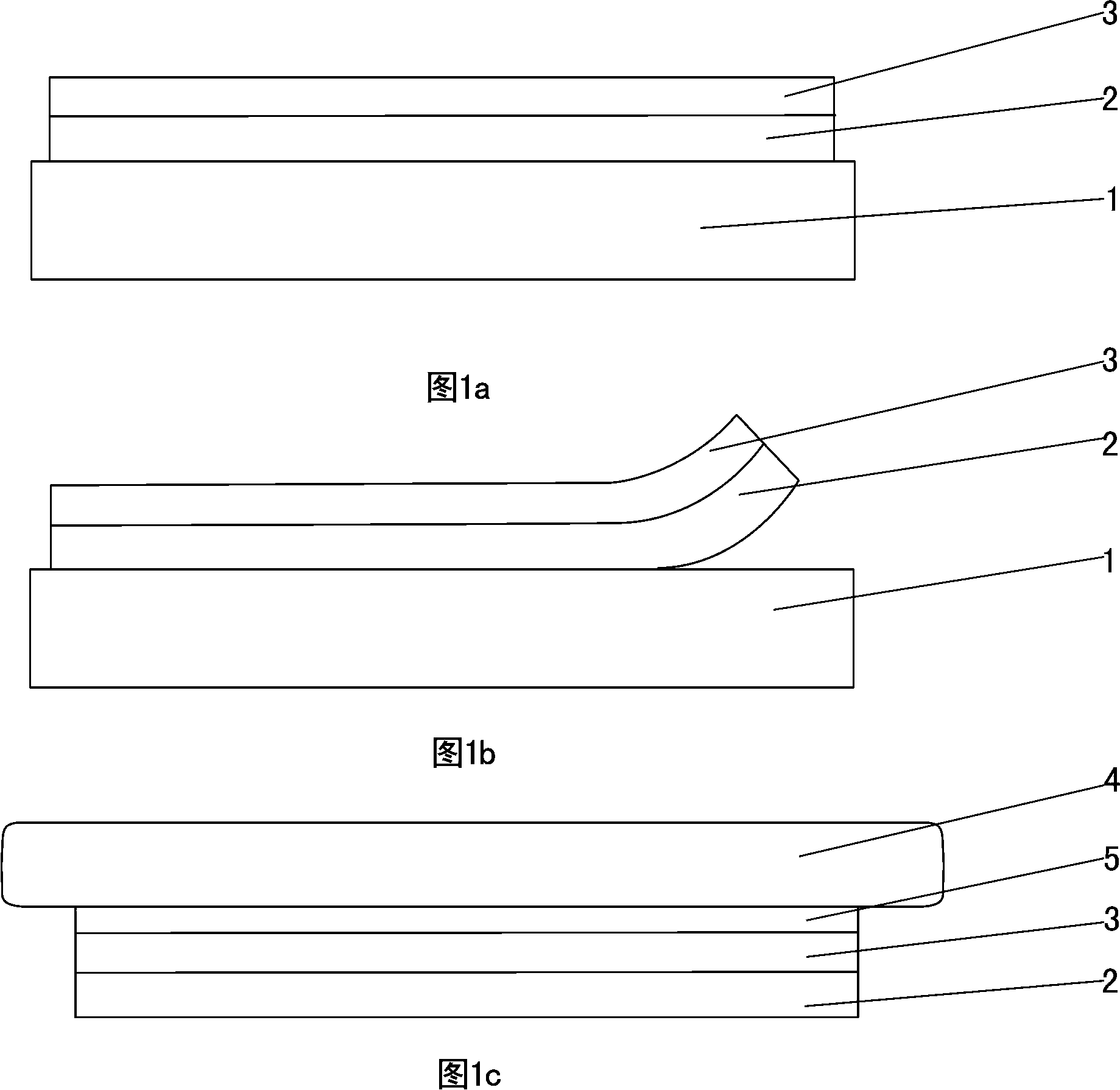

[0041] Such as figure 1 As shown, the manufacturing method of this capacitive touch screen includes the following steps:

[0042] (1) A circuit layer 2 with touch sensing function is formed on a motherboard 1;

[0043] (2) Coating and curing a polymer tough layer 3 on the circuit layer 2, the adhesive force of the tough layer 3 and the circuit layer 2 is greater than the bonding force of the circuit layer 3 and the motherboard 1;

[0044] (3) Separate the tough layer 3 from the motherboard 1, and the circuit layer 2 is adhered to the tough layer 3;

[0045] (4) The protective sheet 4 is adopted, and the first adhesive layer 5 is arranged on the protective sheet 4 (or the tough layer 3);

[0046] (5) Stick the flexible layer 3 on the protective sheet 4, so that the circuit layer 2 is closely attached to the protective sheet 4 through the flexible layer 3, the first adhesive layer 5, and the circuit layer 2, the protective sheet 4, and the flexible layer 3 together constitute a capacitor ...

Embodiment 2

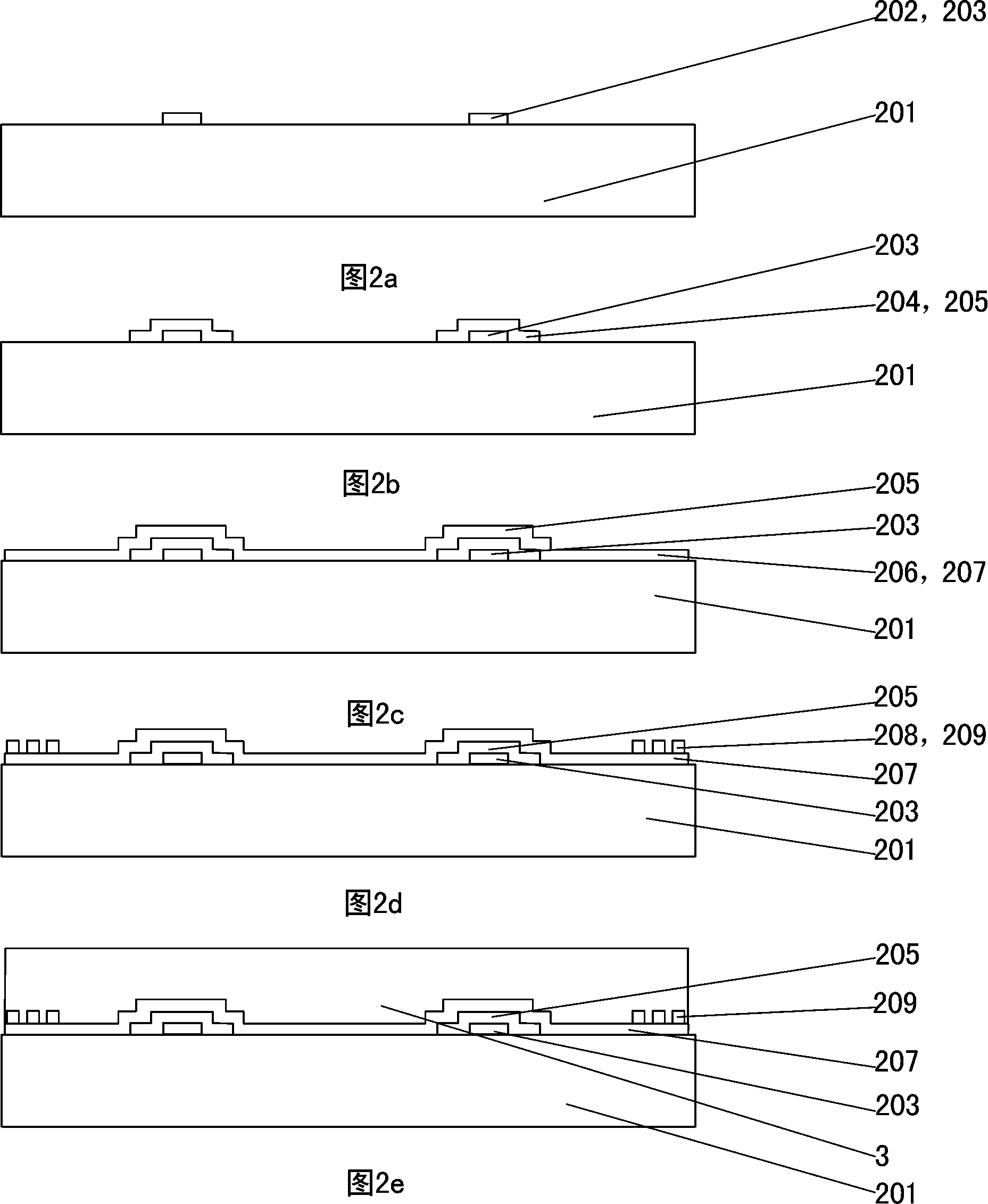

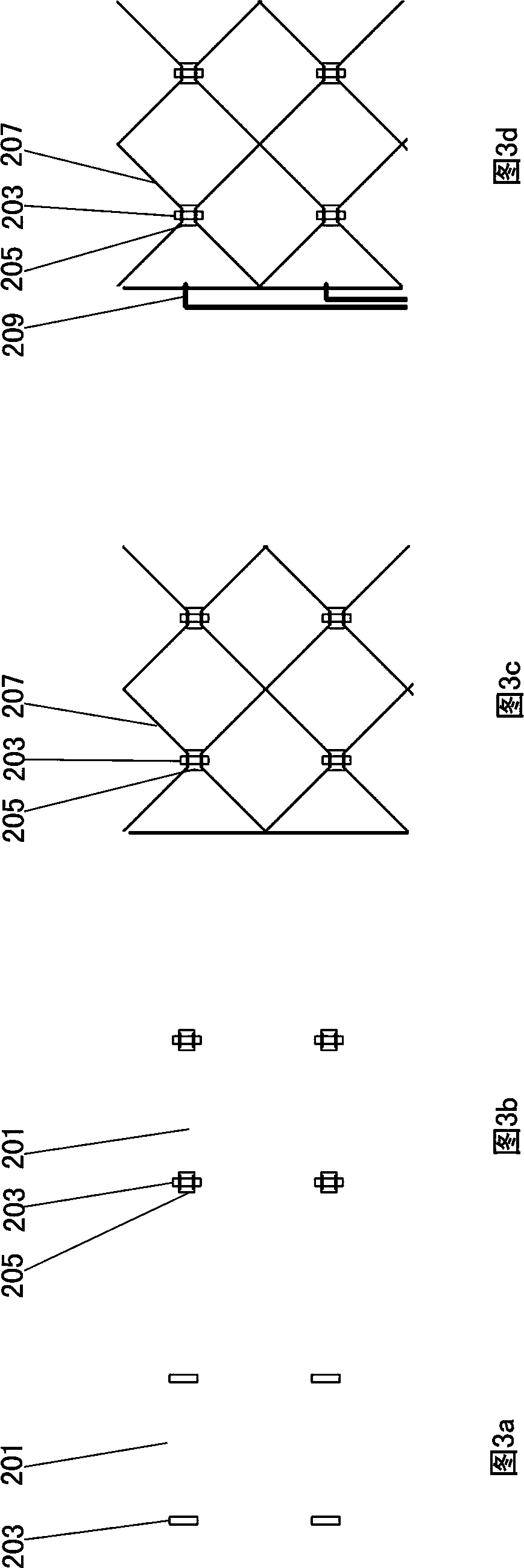

[0055] Such as Figure 5 As shown, when the other parts are the same as the first embodiment, the difference is that the production of the circuit layer includes the following steps:

[0056] (1) A first silver nanowire conductive film 202' is formed on the mother board 201' to form the first sensing electrode of the circuit layer 2'. The first silver nanowire conductive film 202' is made of linear nano silver in the glue Dispersed

[0057] (2) An insulating layer 204' is formed on the first silver nanowire conductive film 202';

[0058] (3) A second silver nanowire conductive film 206' is formed on the insulating layer 204' to form the first sensing electrode of the circuit layer 2'. The second silver nanowire conductive film 206' is made of linear nano silver in the glue Dispersed

[0059] (4) Fabricate the peripheral circuit layer 209'.

[0060] The capacitive touch screen manufactured by the above method is like Image 6 Shown.

Embodiment 3

[0062] Such as Figure 7 with Figure 8 As shown, when the other parts are the same as in the first or second embodiment, the difference is that the circuit layer includes a fingerprint scanning circuit, and the fingerprint scanning circuit includes a plurality of micro-patterned silver nanowire conductive films. The fingerprint detection matrix 11 formed by the electrodes 10, the size of each microelectrode 10 is less than 50μm, each microelectrode 10 contains a plurality of nano silver wires 12, and each nano silver wire 12 is randomly distributed. Both ends constitute a potential probe 13, and the potential probe 13 can detect the potential of the fingerprint based on the principle of capacitance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com