Tensile resistance flat electric cable

A technology of flat cable and tension resistance, which is applied in the field of tension resistance flat cable, can solve the problems of anti-twisting, single cable structure design, etc., and achieve the effect of enhancing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

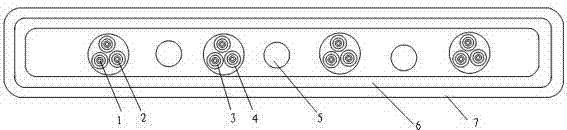

[0015] A tension-resistant flat cable, comprising a conductor 1, an insulated wire core and a sheath 7, the conductor 1 is wrapped with a flame-retardant cross-linked polyolefin insulation layer 2, and the insulation layer 2 is braided with copper wire armor Layer 3, the outer layer of copper wire armor layer 3 is wrapped with flame-retardant cross-linked polyolefin insulation layer II 4 to form an insulated wire core, and three insulated wire cores are combined to form a cable core, and a steel wire rope 5 is arranged between the cable cores; copper wire armor is braided outside the cable core The armor layer II6, the copper wire armor layer II6 is wrapped with a highly flame-retardant and corrosion-resistant flexible neoprene sheath layer 7.

[0016] The cross-sectional area of the conductor is 0.75-2.5 mm 2 , the conductor is formed by twisting 10-50 copper wires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductor cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com