Laminated structure, method for manufacturing the same, and light-emitting device

A technology of layered structure and light-emitting device, which is applied in the direction of multi-layer circuit manufacturing, chemical instruments and methods, coating, etc., can solve problems such as limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

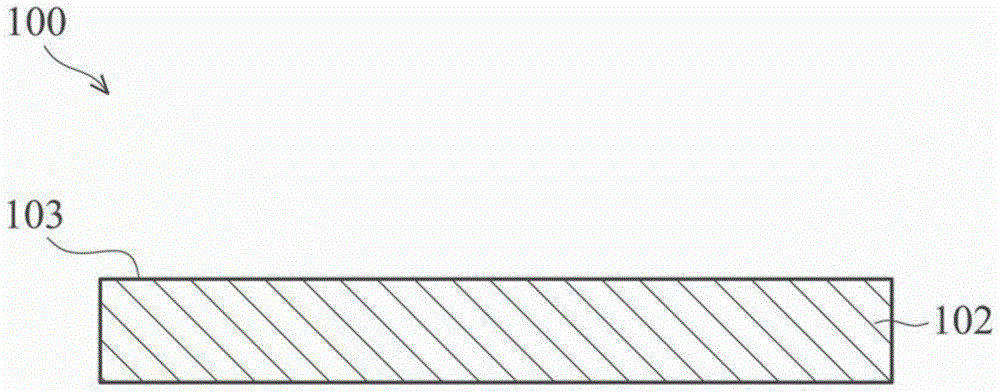

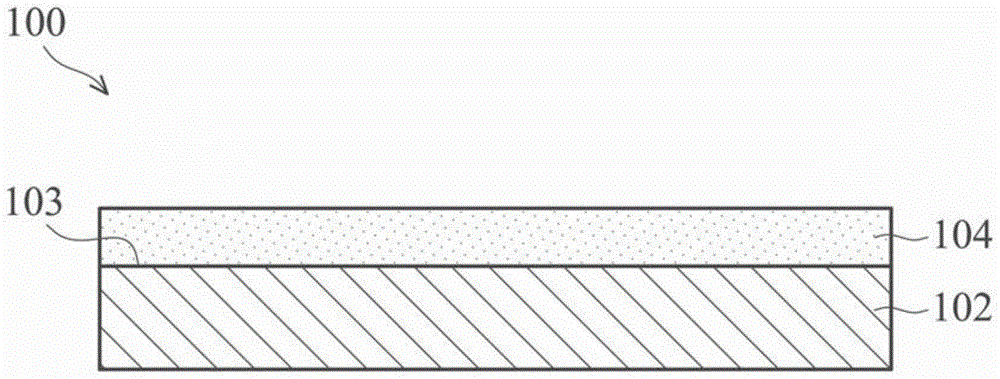

Embodiment 1

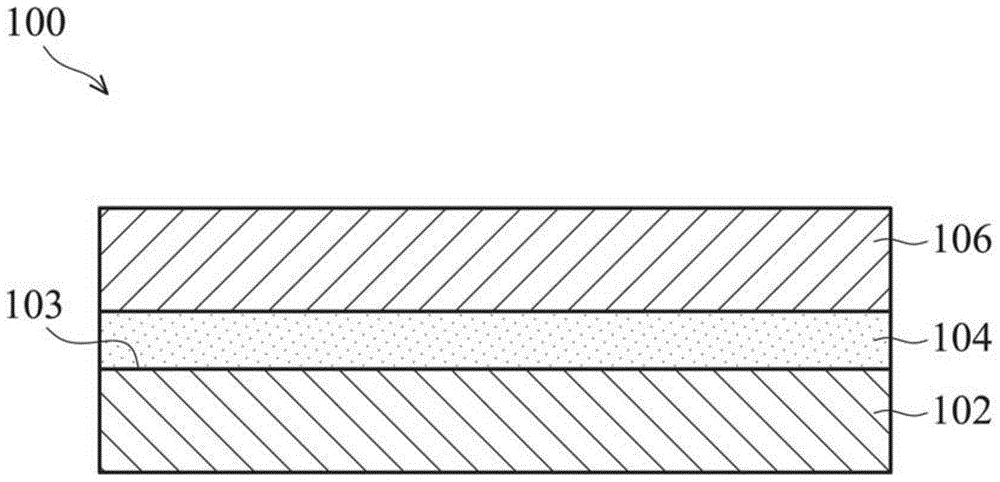

[0034] Place the SUS 304 stainless steel substrate in the deposition chamber, and keep the chamber in a vacuum state. Next, Ar was introduced at a flow rate of 100 sccm to maintain the chamber pressure at 60 mtorr, and the surface of the stainless steel substrate was treated with 100 W 13.56 MHz radio frequency plasma for about 1 min. Next, HMDSO was injected into the deposition chamber with a flow rate of 100 sccm, and at a pressure of 40 mtorr, a 100 W 13.56 MHz radio frequency plasma was used for 10 min to form an interposer layer. The film thickness of the interposer is about 120nm, and the ratio of Si-C bonds to Si-O bonds is about 0.3.

[0035] Put 10 g of solid powder of p-xylene dimer in an evaporation chamber and heat to 150° C. to sublimate p-xylene into a gaseous state. Next, gaseous p-xylene is passed into a thermal cracking chamber with a temperature of about 650° C. for pyrolysis, and the pyrolyzed p-xylene monomer is sent to a deposition chamber with a temperat...

Embodiment 2

[0037] The same procedure as in Example 1 was carried out, but the flow rate of HMDSO was 150 sccm. In this embodiment, the ratio of Si-C bonds to Si-O bonds in the interposer is about 0.5.

Embodiment 3

[0039] The same steps as in Example 1 were carried out, but the flow rate of HMDSO was 200 sccm. In this embodiment, the ratio of Si-C bonds to Si-O bonds in the interposer is about 0.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com